Process for preparing cationic nanotube array intermingling titanium oxide

A technology of titanium oxide nanotubes and cations, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as difficult uniform doping, and achieve easy recovery and high-efficiency in-situ cation doping , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

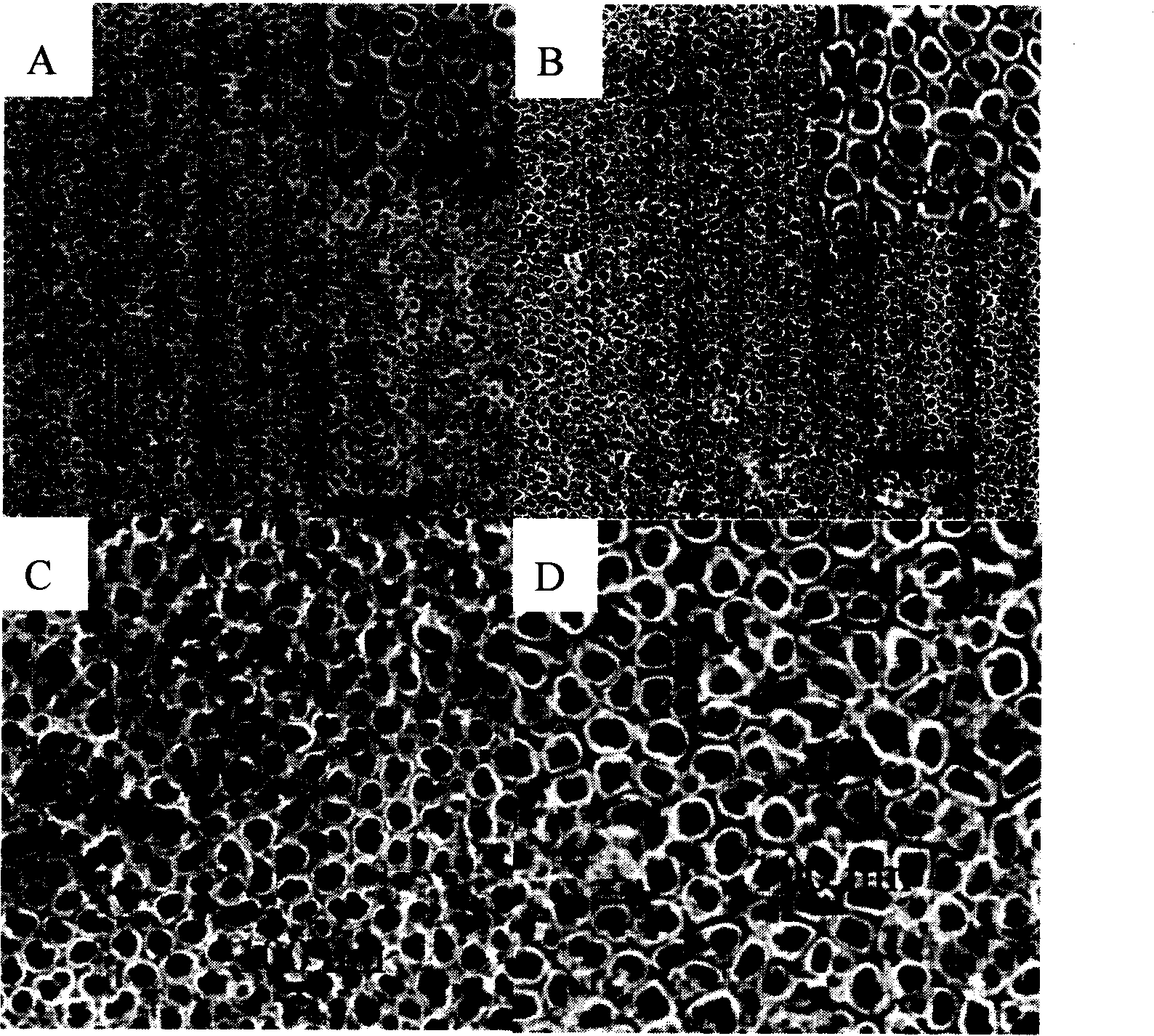

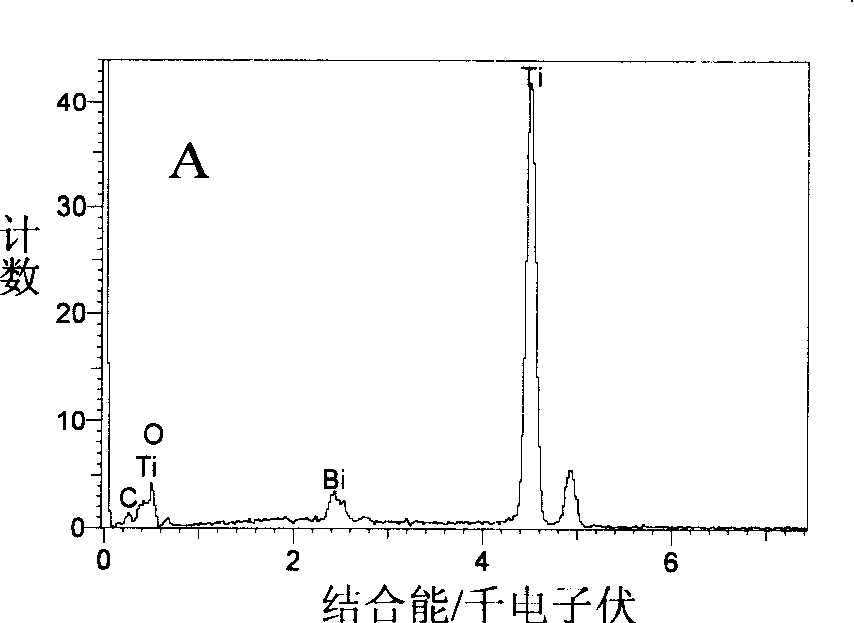

Embodiment 1

[0026] The prepared titanium-bismuth alloy was cut into thin slices of 20mm×8mm×0.5mm, and titanium oxide nanotubes were grown on the titanium-bismuth alloy substrate by anodic oxidation process, and the molar content of the alloying element bismuth was 3%. The alloy titanium sheet is heat-treated in a nitrogen atmosphere of 2000Pa, the treatment temperature is 1200°C, and the holding time is 30h, until the residual stress in the alloy titanium sheet is eliminated, and the treated titanium sheet is cleaned in cleaning solvent ethanol and dried. The platinum sheet is used as the cathode, the titanium-bismuth alloy is used as the anode, and the electrolyte is 1M Na 2 SO 4 solution, wherein a certain amount of NaF is added, and the weight concentration of NaF is 1.2%. Apply an external voltage of 20V and oxidize at room temperature for 8 hours until the electrolyte turns milky white. Wash the prepared titanium oxide nanotubes with deionized water. At this time, they are amorphou...

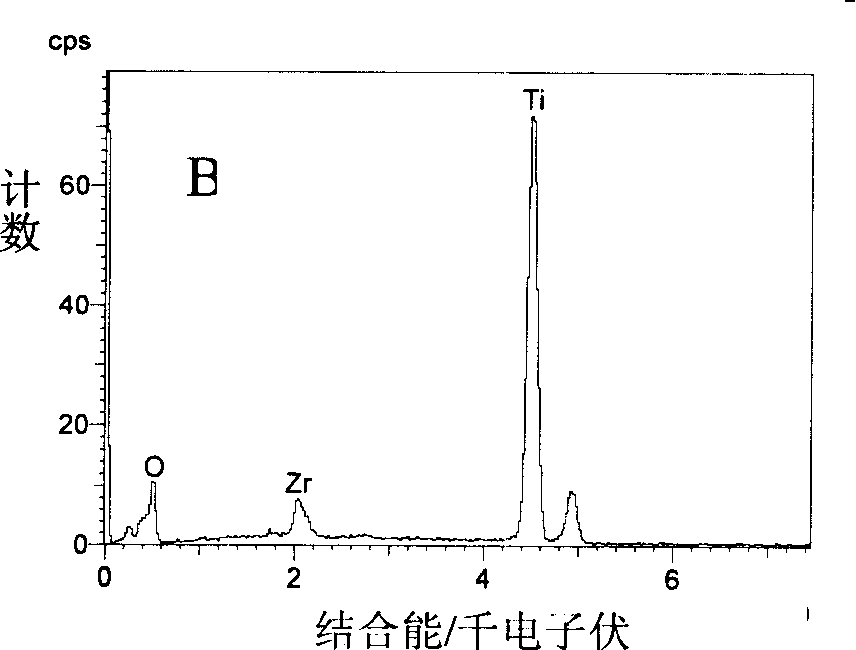

Embodiment 2

[0029] The prepared titanium-zirconium alloy was cut into thin slices of 20mm×8mm×0.5mm, and titanium oxide nanotubes were grown on the titanium-zirconium alloy substrate by anodic oxidation process, and the molar content of alloy element zirconium was 6%. The titanium alloy sheet is heat treated in a nitrogen atmosphere of 4000Pa, the treatment temperature is 1250°C, and the holding time is 36h, until the residual stress in the titanium-zirconium alloy sheet is eliminated, and the treated titanium sheet is washed in cleaning solvent water and dried. The platinum sheet is used as the cathode, the titanium-zirconium alloy is used as the anode, and the electrolyte is 1M Na 2 SO 4 solution, wherein a certain amount of NaF is added, and the weight concentration of NaF is 2%. After applying an external voltage of 25V and oxidizing at room temperature for 5 hours, until the electrolyte turns milky white, the prepared titanium oxide nanotubes are washed with deionized water, and at ...

Embodiment 3

[0032]The prepared titanium-aluminum alloy was cut into thin slices of 20mm×8mm×0.5mm, and titanium oxide nanotubes were grown on the titanium-aluminum alloy substrate by anodic oxidation process, and the molar content of alloying element aluminum was 6%. The alloy titanium sheet is heat-treated in a nitrogen atmosphere of 10000Pa, the treatment temperature is 1000°C, and the holding time is 24h, until the residual stress in the titanium-aluminum matrix is eliminated, and the treated titanium sheet is washed in cleaning solvent water and dried. The platinum sheet is used as the cathode, the titanium aluminum alloy is used as the anode, and the electrolyte is 1M Na 2 SO 4 solution, wherein a certain amount of NaF is added, and the weight concentration of NaF is 1%. After applying an external voltage of 20V and oxidizing at room temperature for 8 hours until the electrolyte turns milky white, the prepared titanium oxide nanotubes are washed with deionized water, and at this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com