Preparation method of zinc-doped titanium dioxide nano-tube array

A nanotube array, titanium dioxide technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of reducing electrolyte concentration, lack of universality, and difficulty in ions entering, achieving high quantum effect, combined with Firm, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Polish the pure titanium foil until there is no scratch on the surface, clean it and set aside;

[0023] (2) prepare electrolyte: electrolyte is the mixed solution that is the hydrofluoric acid of 40wt% and deionized water preparation by HF content, and the content of HF is 0.3wt% in the electrolyte;

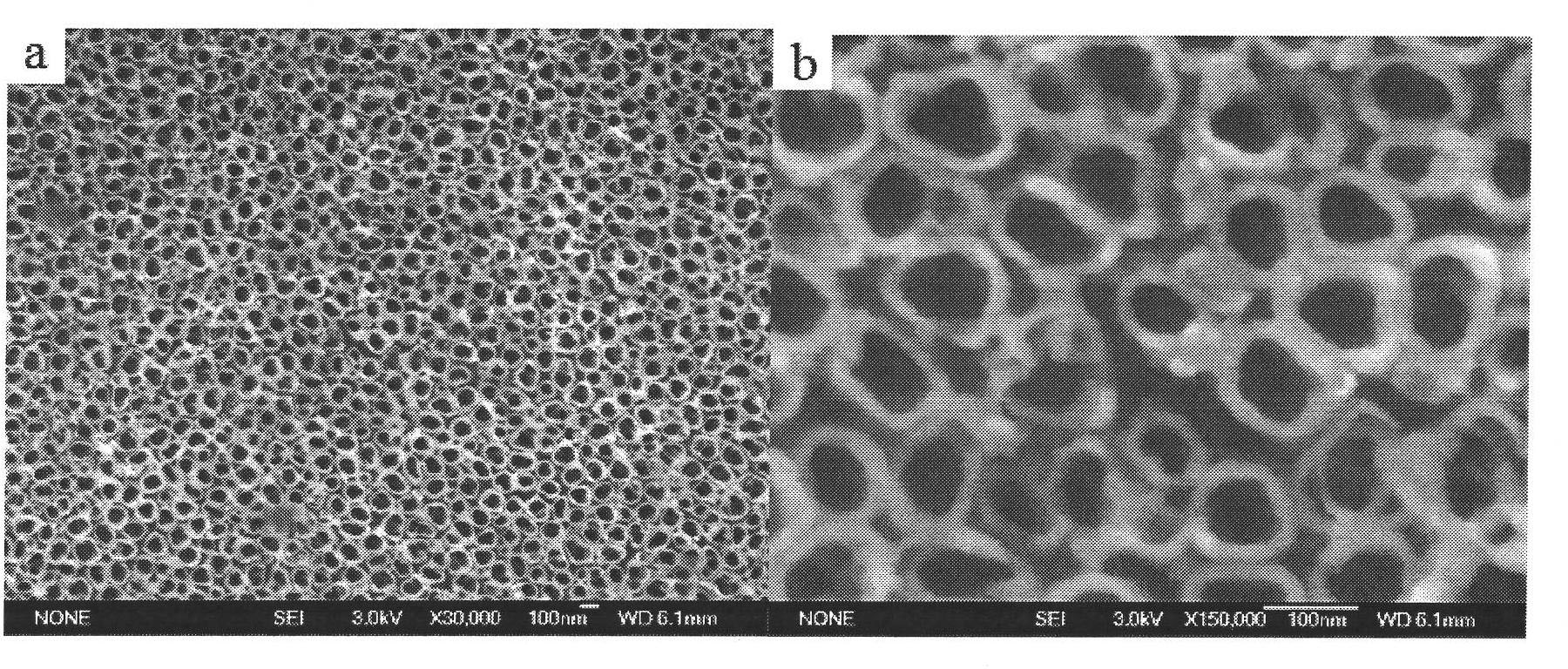

[0024] (3) Under 20V DC voltage, with pure titanium foil as the anode and platinum sheet as the cathode, keeping the distance between the two electrodes at 30mm, anodic oxidation is carried out in the electrolyte, and the oxidation time is 4h, and the amorphous titanium dioxide nanotube array is prepared ;

[0025] (4) Preparation of zinc-doped titania nanotube arrays: use the titania nanotube arrays prepared above as cathode, platinum sheet as anode, and 0.1mol / L Zn(NO 3 ) 2 The solution is an electrolyte, and the electrochemical deposition is carried out at a DC voltage of 0.4V for 60 minutes;

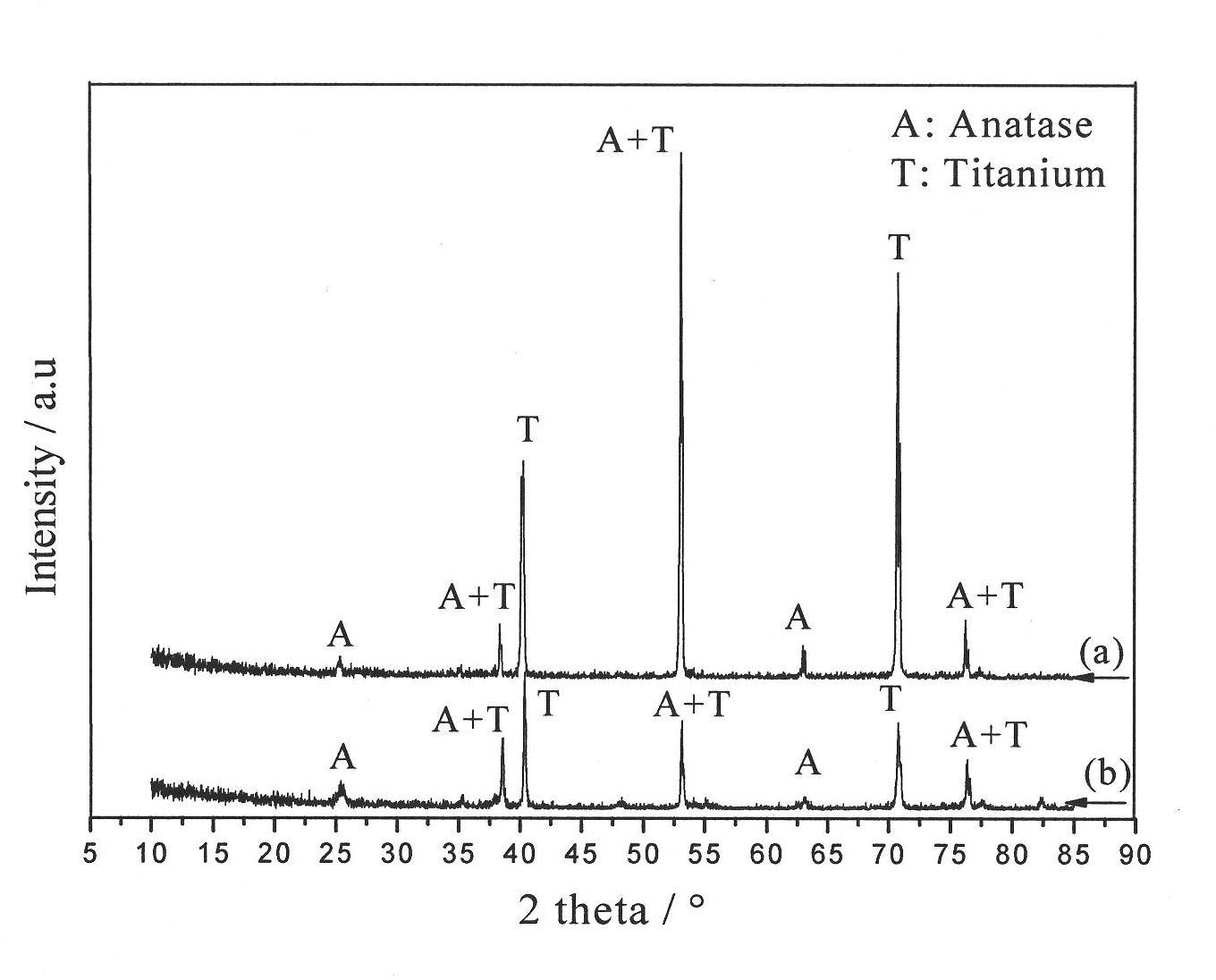

[0026] (5) Put the electrochemically deposited titanium dioxide nano...

Embodiment 2

[0028] (1) Polish the pure titanium foil until there is no scratch on the surface, clean it and set aside;

[0029] (2) prepare electrolyte: electrolyte is the mixed solution that is the hydrofluoric acid of 40wt% and deionized water preparation by HF content, and the content of HF is 0.5wt% in the electrolyte;

[0030] (3) Under 30V DC voltage, using pure titanium foil as the anode and platinum sheet as the cathode, keeping the distance between the two electrodes at 40mm, anodizing in the electrolyte, the oxidation time is 3h, and the amorphous titanium dioxide nanotube array is prepared ;

[0031] (4) Preparation of zinc-doped titania nanotube array: use the titania nanotube array prepared above as cathode, platinum sheet as anode, and 0.2mol / L Zn(NO 3 ) 2 The solution is an electrolyte, and electrochemical deposition is carried out at a DC voltage of 0.6V for 30 minutes;

[0032] (5) Put the electrochemically deposited titanium dioxide nanotube array into a muffle furnac...

Embodiment 3

[0034] (1) Polish the pure titanium foil until there is no scratch on the surface, clean it and set aside;

[0035] (2) prepare electrolyte: electrolyte is the mixed solution that is the hydrofluoric acid of 40wt% and deionized water preparation by HF content, and the content of HF is 0.7wt% in the electrolyte;

[0036] (3) Under 40V DC voltage, with pure titanium foil as the anode and platinum sheet as the cathode, keeping the distance between the two electrodes at 50 mm, anodic oxidation is carried out in the electrolyte, and the oxidation time is 2 hours, and the amorphous titanium dioxide nanotube array is prepared ;

[0037] (4) Preparation of zinc-doped titania nanotube array: use the titania nanotube array prepared above as cathode, platinum sheet as anode, and 0.3mol / L Zn(NO 3 ) 2 The solution is an electrolyte, and the electrochemical deposition is carried out at a DC voltage of 0.5V for 60 minutes;

[0038] (5) Put the electrochemically deposited titanium dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com