Titanium alloy surface self-lubricating layer and preparation method thereof

A self-lubricating layer, titanium alloy technology, applied in surface reaction electrolytic coating, metal material coating process, coating and other directions, can solve the problems of load-carrying capacity solid lubricant loss, large temperature change, reducing friction coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

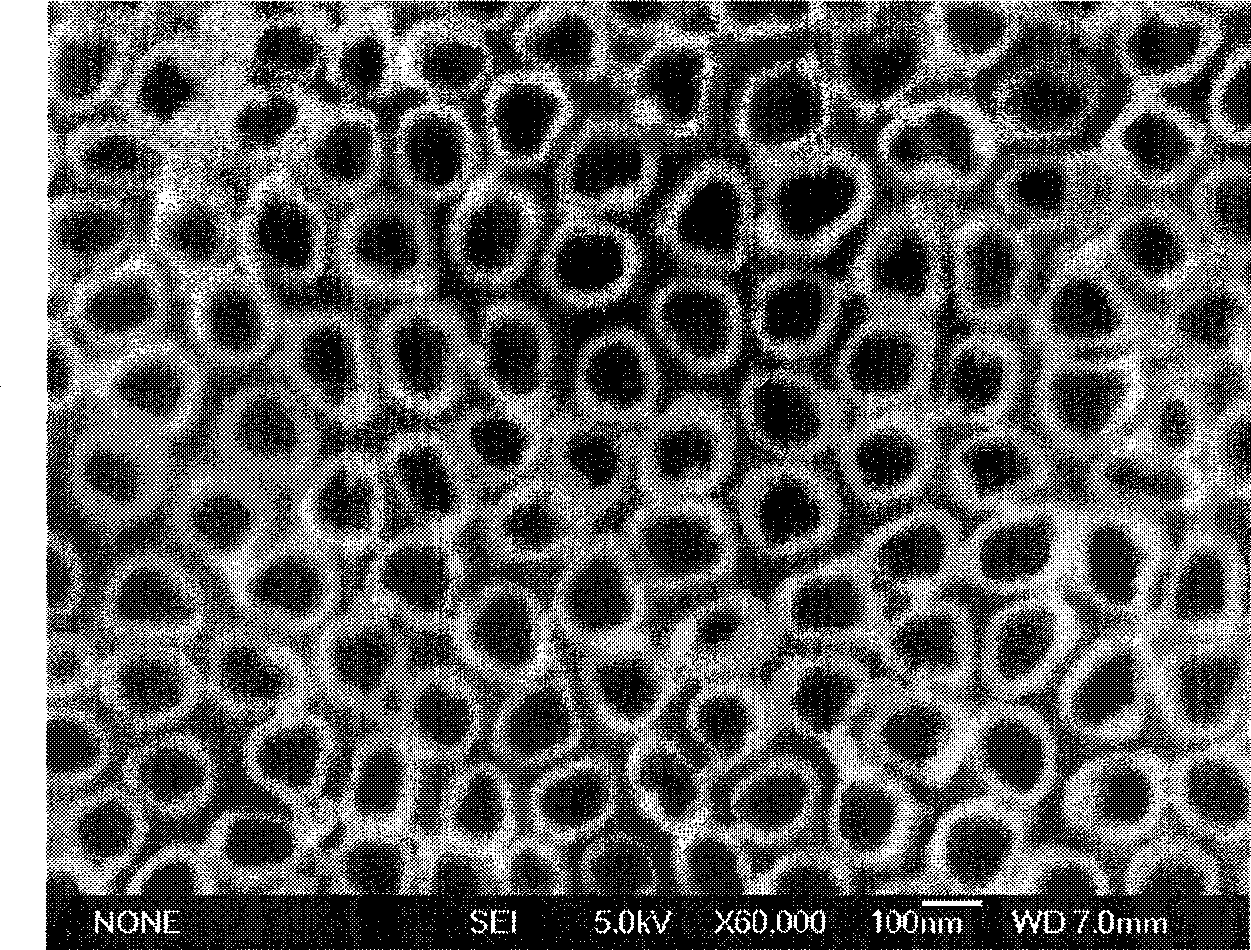

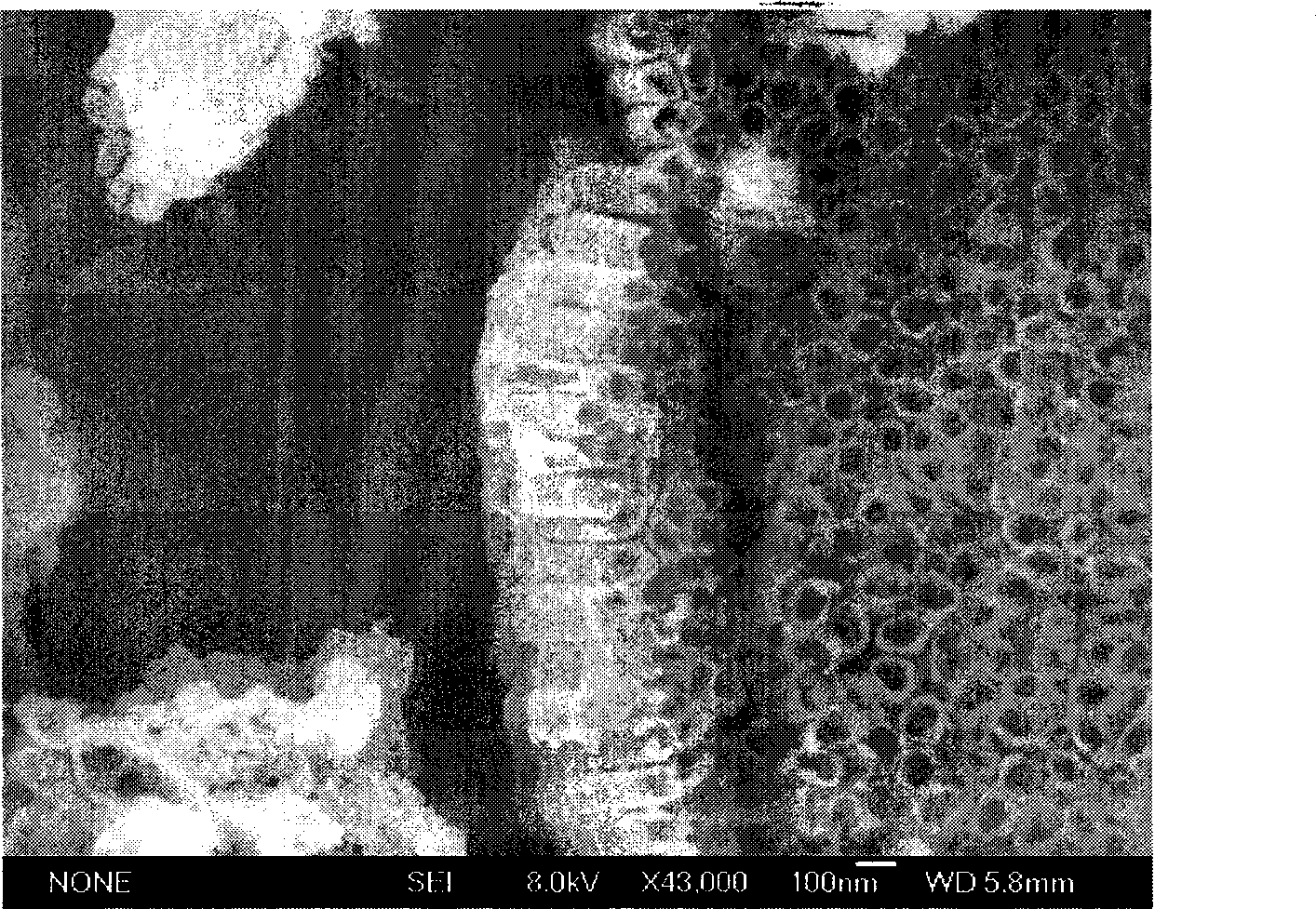

[0027] Embodiment 1: Prepare titania nanotube array on the surface of titanium alloy workpiece (1)

[0028] Prepare ammonium sulfate / ammonium fluoride mixed electrolyte at room temperature, take an appropriate amount of analytically pure ammonium sulfate and ammonium fluoride and mix it into ionized water, so that the molar concentration of ammonium sulfate in the mixed electrolyte is 1M, and the molar concentration of ammonium fluoride is 0.14M, pour into the electrolytic cell after completely dissolved. Clean the surface of the Ti-6Al-4V alloy workpiece with distilled water and acetone respectively, then immerse the titanium alloy workpiece in the electrolytic cell, and keep the distance between the surface of the titanium alloy workpiece and the high-purity graphite electrode at 5 cm. Connect the titanium alloy workpiece to the positive pole of the DC power supply, and the graphite to the negative pole, then keep applying a DC voltage of 25V for 20 minutes, and keep the tem...

Embodiment 2

[0031] Embodiment 2: Prepare titania nanotube array on the surface of titanium alloy workpiece (2)

[0032] Prepare phosphoric acid / ammonium fluoride mixed electrolyte at room temperature, weigh an appropriate amount of analytically pure phosphoric acid and ammonium fluoride and mix it into ionized water, so that the molar concentration of phosphoric acid in the mixed electrolyte is 0.3M, and the molar concentration of ammonium fluoride is 0.14M , and pour it into the electrolytic cell after completely dissolving. Clean the surface of the Ti-6Al-4V alloy (or other titanium-based alloy) workpiece and then immerse it in the electrolytic cell, keeping the distance between the surface of the titanium alloy workpiece and the high-purity graphite electrode at 5 cm. A DC voltage of 25V was kept applied between the titanium alloy workpiece and the graphite for 20 minutes, and the temperature of the electrolyte was maintained at 18-25°C. The titanium alloy workpiece is taken out and c...

Embodiment 3

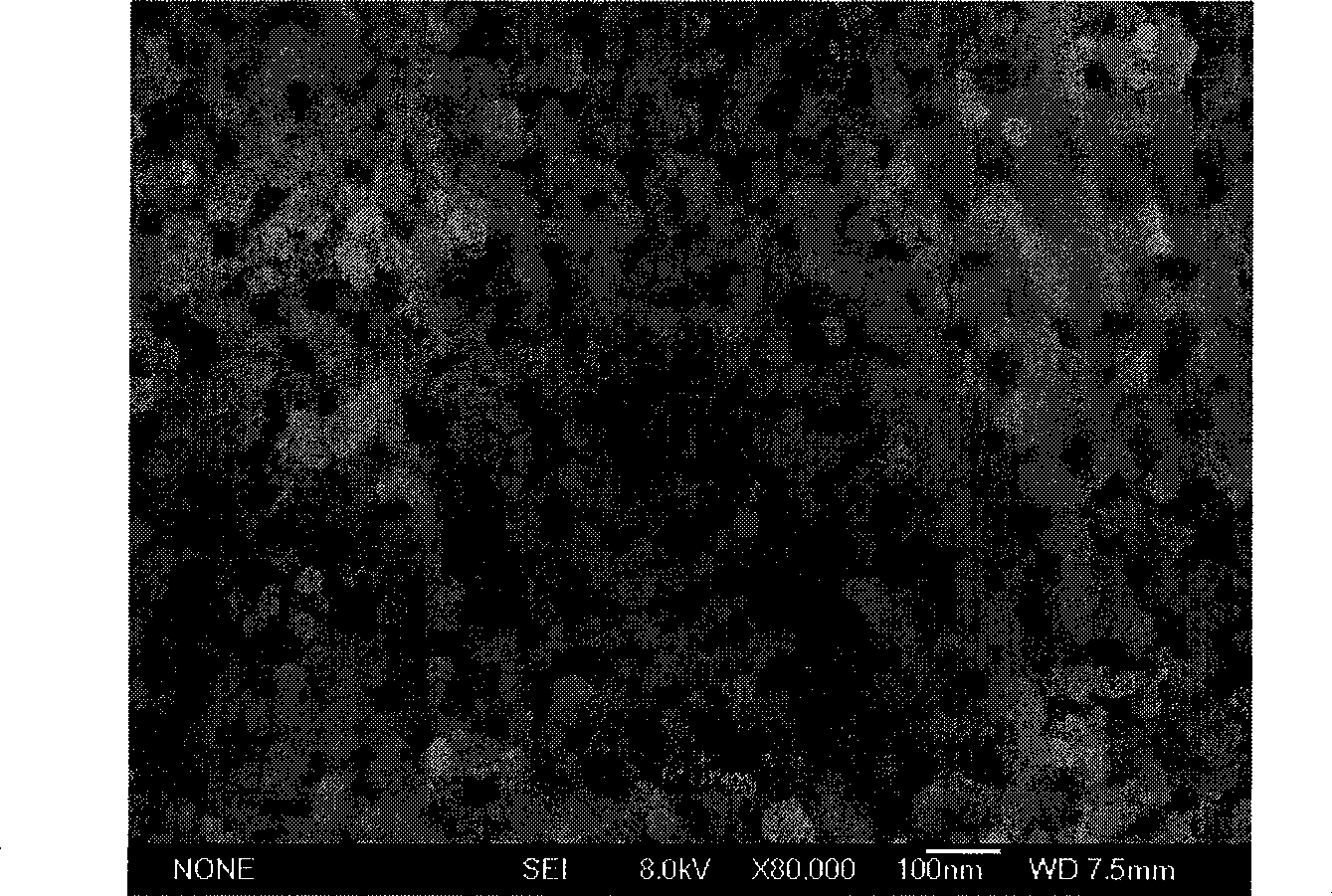

[0034] Embodiment 3: the preparation process of IF-WS2 nanoparticles

[0035] The first step is the preparation of spherical tungsten trioxide nanoparticles.

[0036] Prepare a 3 M HCl solution and a 0.5 M Na solution with deionized water at room temperature. 2 WO 4 solution. Take 500ml ethanol and 1500ml Na 2 WO 4 The solution was fully mixed, and under the synergistic effect of ultrasonic and mechanical stirring, the HCl solution was slowly and uniformly dropped into the reaction system through the dropping funnel until the pH ≈ 1.0, and then maintained ultrasonic and stirred for 30 minutes, and the reaction system became a stable white suspension. Cloudy liquid. The reactants were separated by a centrifuge, washed three times with deionized water, and washed twice with absolute ethanol. Dry in a vacuum oven at 80°C for 6h, and then calcinate in a resistance furnace at 500°C for 2h to obtain about 160 grams of spherical WO with a particle size of 30-60nm. 3 nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pipe diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com