Low-concentration copper-doped titanium dioxide nanotube photocatalyst and preparation method thereof

A technology of titanium dioxide and photocatalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of low stability of doping metal doping, complicated process, and unfavorable large-scale production. , to achieve a clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0010] The preparation of example 1 pure titania nanotube catalyst

[0011] (1) First cut the titanium plate and the nickel plate into several rectangles with equal area of 4cm×10cm. Then the cut titanium sheet and nickel sheet were polished with metallographic sandpaper until there were no scratches on the surface, and the oxide layer on the surface of the titanium sheet was removed, followed by ultrasonic cleaning in distilled water, acetone, and distilled water for 25 minutes, and finally placed in air to dry .

[0012] (2) Select 0.5wt% NH 4 F+0.3M(NH 4 ) 2 SO 4 +glycerin+water (volume ratio 2:1) is the electrolyte, using a DC stabilized power supply, the titanium sheet is used as the anode, the nickel sheet is used as the cathode, the voltage is 30V, the anodic oxidation time is 2h, and a magnetic stirrer is used for stirring, room temperature ( 25°C) for anodic oxidation.

[0013] (3) After the reaction, wash the sample with distilled water and dry it in the air....

example 2

[0014] The preparation of example 2 copper-doped titania nanotubes

[0015] (1) Doping pretreatment, pure TiO prepared by anodic oxidation 2 Nanotubes should be soaked in acetone for 5 minutes before doping, and washed with distilled water to remove reducing substances on the nanotubes.

[0016] (2) Using a DC regulated power supply with a range of 0-30V to prepare amorphous pure TiO 2 The nanotube is the cathode, the nickel sheet is the anode, 0.01M copper sulfate is selected as the electrolyte, the voltage is 0.5V, the electrochemical deposition time is 1h, the magnetic stirrer is used for stirring, and the electrodeposition reaction is carried out at room temperature (25°C).

[0017] (3) Prepared copper-doped TiO 2 The nanotubes were rinsed with distilled water and left to air dry.

[0018] (4) Put the prepared copper-doped titanium dioxide nanotubes into a tubular resistance furnace for calcination in air for 2 h, the calcination temperature is 500 °C, 600 °C, 700 °C, a...

example 3

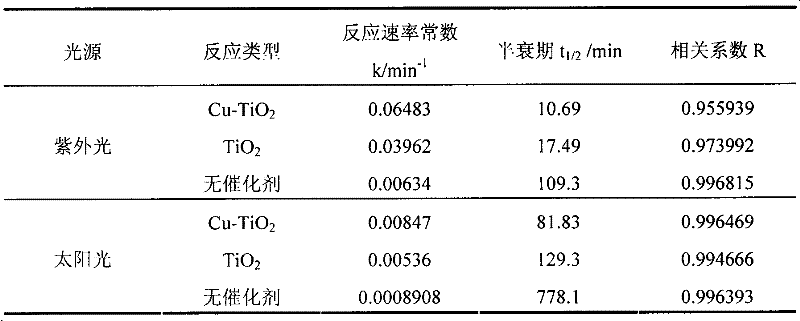

[0019] Example 3 Application example of low concentration copper-doped titanium dioxide nanotube photocatalytic degradation of methyl orange

[0020] Using the prepared low-concentration copper-doped titanium dioxide nanotubes to carry out the experiment of ultraviolet photocatalytic degradation of methyl orange, the concentration of methyl orange is 20mg L -1 , with a 400W high-pressure mercury lamp as the ultraviolet light source, the degradation rate of methyl orange was 89.9% after irradiating for 60 minutes, and the catalyst still had a high degradation rate after repeated use.

[0021] Using the prepared low-concentration copper-doped titanium dioxide nanotubes to carry out the solar photocatalytic degradation experiment of methyl orange, the concentration of methyl orange is 5mg L -1 , select sunlight (Nanjing, China, mid-August, direct sunlight during 12:00-14:00) as the light source, after 120 minutes of sunlight irradiation, the methyl orange degradation rate of copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com