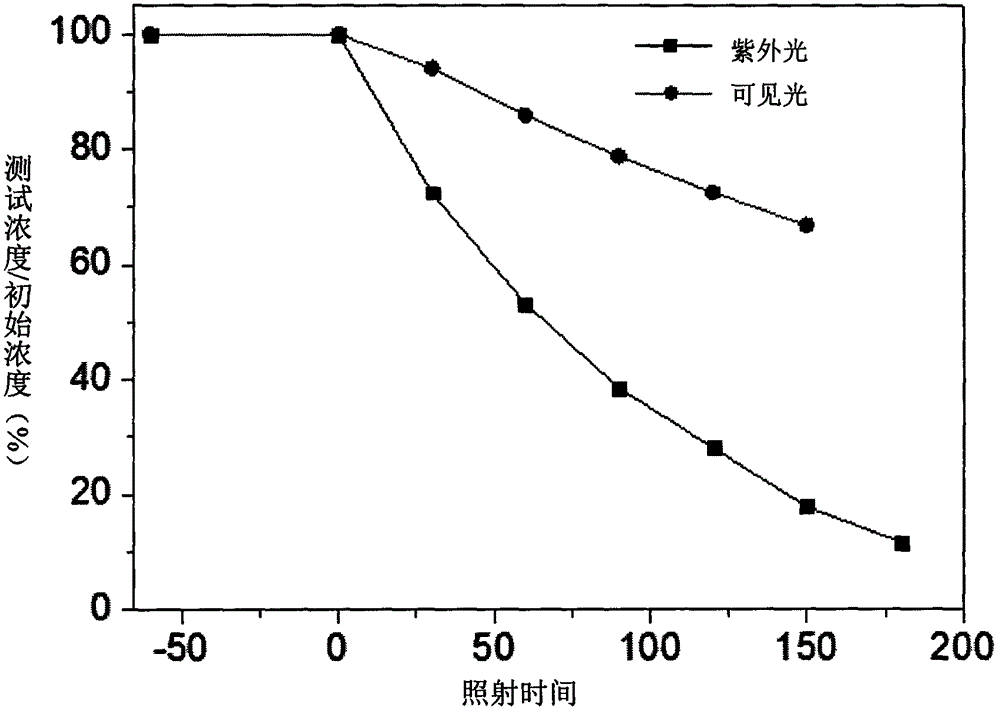

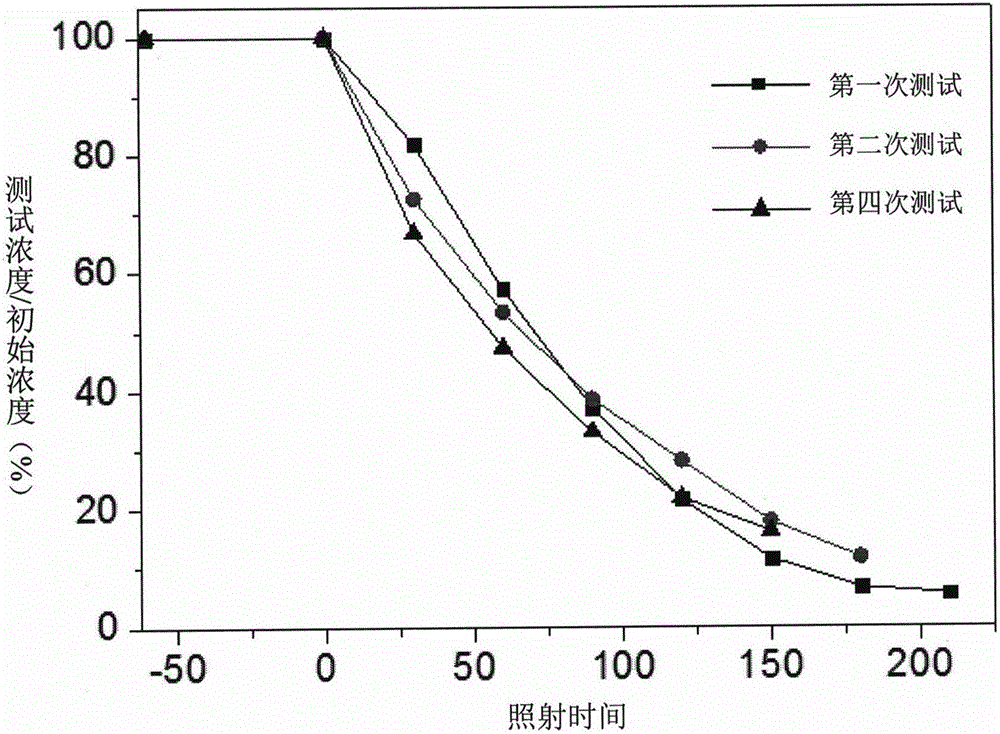

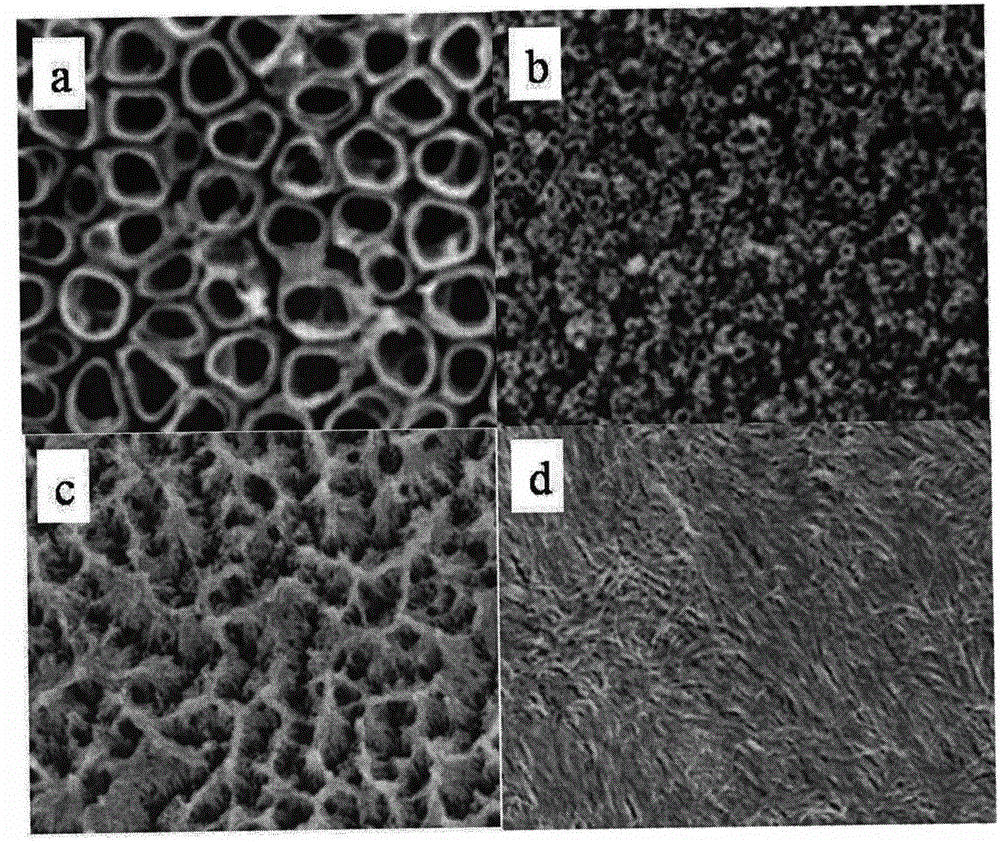

Anodic oxidation preparation method for titanium dioxide nanotube array photocatalyst for degrading rhodamine B

A technology of nanotube array and anodic oxidation method, which is applied in the field of preparation of nano-photocatalytic environmental protection materials, can solve problems such as needs, cumbersome recycling and complicated processes, and achieve the effects of easy recycling and good catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. First, place the titanium sheet in an acid mixed solution for pickling for 5 minutes, then ultrasonically clean the titanium sheet in an organic solution and deionized water for 10 minutes, and finally dry the cleaned titanium sheet at room temperature for use.

[0029] 2. Configure 0.27M NH 4 F, a mixed solution of water and glycerol (1:1, v / v) was stirred evenly as the electrolyte for the anodic oxidation process.

[0030] 3. The anode and cathode are pretreated titanium sheets and platinum wires for electrochemical anodic oxidation respectively. The distance between the two electrodes is 1-4cm, and the voltage is boosted from 0V to 20V at a boost rate of 150-300mV / s and then stopped and maintained. 1~3h.

[0031] 4. After the anodic oxidation reaction, turn off the power, take out the titanium sheet of the anode and rinse it with deionized water to remove the electrolyte adsorbed on the surface, and then dry it at room temperature.

[0032] 5. Put the titanium d...

Embodiment 2

[0035] 1. First, place the titanium sheet in an acid mixed solution for pickling for 5 minutes, then ultrasonically clean the titanium sheet in an organic solution and deionized water for 10 minutes, and finally dry the cleaned titanium sheet at room temperature for use.

[0036] 2. Configure 0.27M NH 4 F, a mixed solution of water and glycerol (1:1, v / v) was stirred evenly as the electrolyte for the anodic oxidation process.

[0037] 3. The anode and cathode are pretreated titanium sheets and platinum wires for electrochemical anodic oxidation respectively. The distance between the two electrodes is 1-4cm, and the voltage is boosted from 0V to 20V at a boost rate of 150-300mV / s and then stopped and maintained. 1~3h.

[0038] 4. After the anodic oxidation reaction, turn off the power, take out the titanium sheet of the anode and rinse it with deionized water to remove the electrolyte adsorbed on the surface, and then dry it at room temperature.

[0039] 5. Put the titanium d...

Embodiment 3

[0042] 1. First, place the titanium sheet in an acid mixed solution for pickling for 5 minutes, then ultrasonically clean the titanium sheet in an organic solution and deionized water for 10 minutes, and finally dry the cleaned titanium sheet at room temperature for use.

[0043] 2. Configure 0.1M NH 4 F, water and 0.5M (NH 4 ) 2 SO 4 The mixed solution was stirred evenly as the electrolyte solution for the anodizing process.

[0044] 3. The anode and the cathode are pretreated titanium sheets and platinum wires for electrochemical anodization, the distance between the two electrodes is 2em, and the voltage is boosted from 0V to 20V at a boost rate of 150-300mV / s and then stopped and maintained at 1~ 3h.

[0045] 4. After the anodic oxidation reaction, turn off the power, take out the titanium sheet of the anode and rinse it with deionized water to remove the electrolyte adsorbed on the surface, and then dry it at room temperature.

[0046] 5. Put the titanium dioxide nanot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com