Method for synthesizing and purifying tulathromycin impurity E

A technology of teramycin and impurities, applied in the field of medicinal chemistry, can solve the problems of low purity of tebramycin impurity E, unable to meet the structure and properties, difficult to control the synthesis process, etc., to improve the purity, promote the transformation efficiency, and improve the properties stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

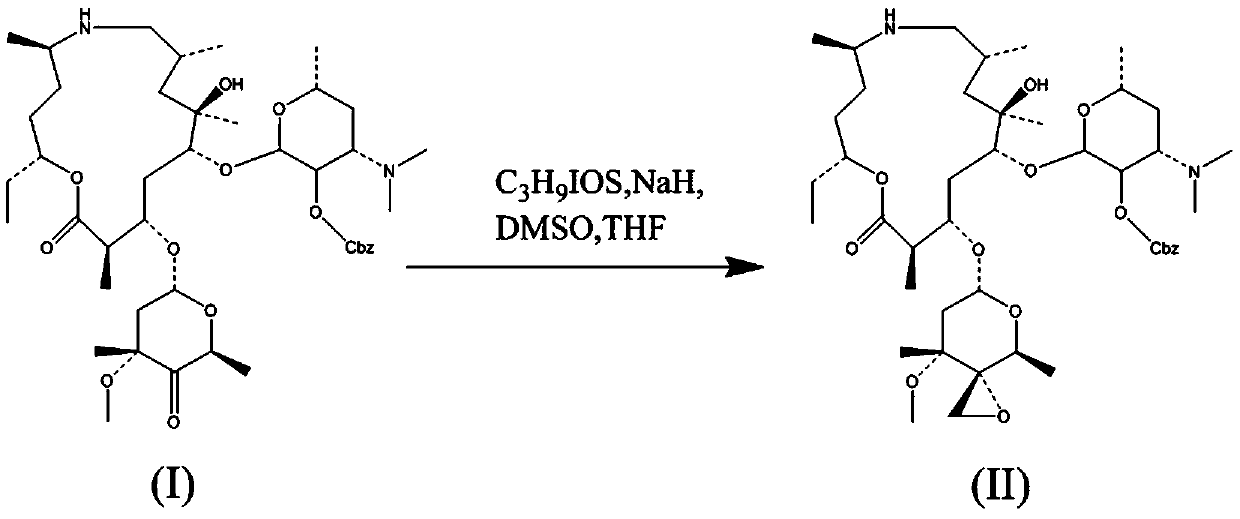

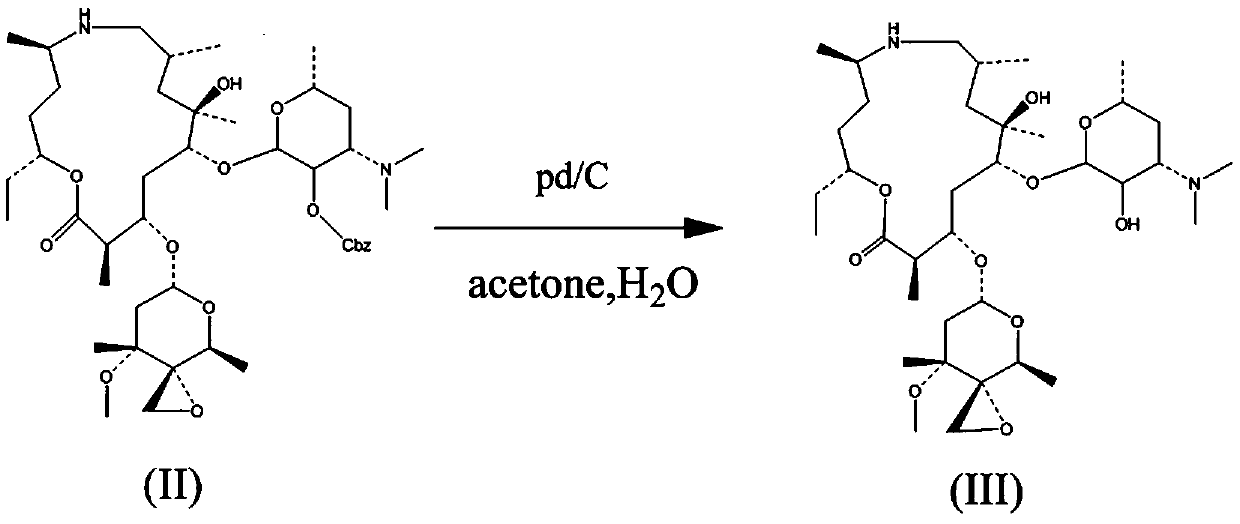

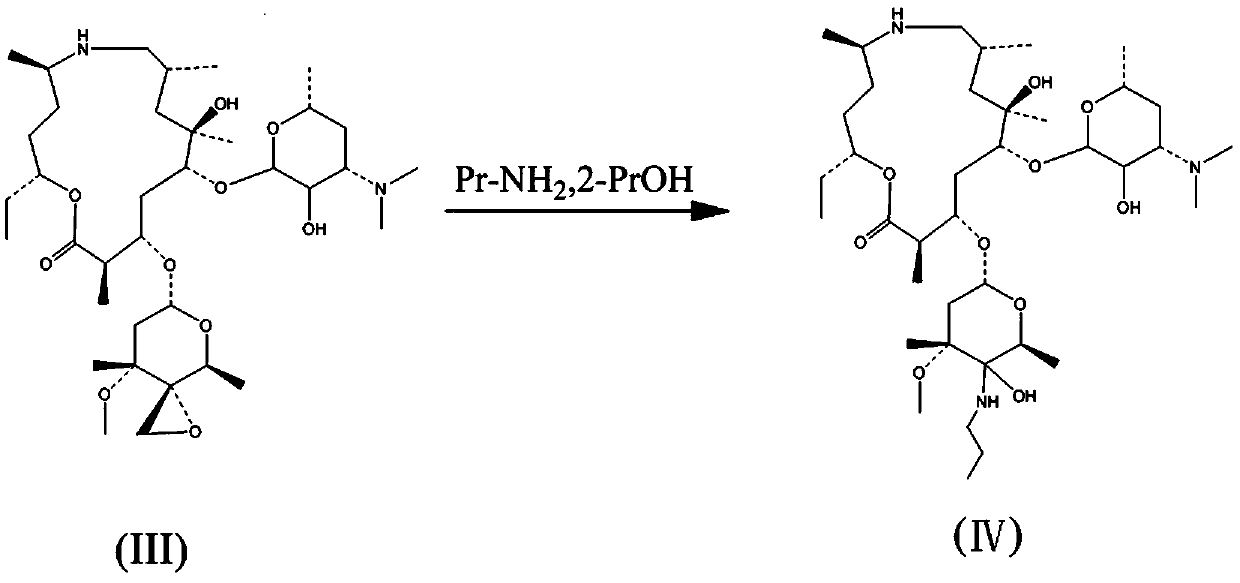

[0034] The method for synthesizing and purifying telamycin impurity E of the present embodiment comprises the following steps:

[0035] (1) Add 3.0 g of potassium hexamethyldisilazide, 100 ml of DMSO and tetrahydrofuran to a 500 ml four-necked flask, stir to dissolve, and feed N 2 For protection, add 15.7 g of trimethylsulfoxide iodide in portions, control the temperature at 0° C., and keep stirring at this temperature for 2 hours; add the DMSO solution (30 g+100 ml) of telamycin oxide dropwise, and control the dropping temperature at 30°C, after the dropwise addition, keep it at -50°C for 1 hour, take a sample for detection, epoxy ketone isomer: epoxy compound = 85:15, add the reaction solution to 10% ammonium chloride aqueous solution, and quench the reaction , the reaction solution was layered, and after washing with brine, the organic phase was concentrated to dryness to obtain 30.4 g of the crude product of epoxy ketone isomers;

[0036] (2) The crude product of epoxy ke...

Embodiment 2

[0041] The method for synthesizing and purifying telamycin impurity E of the present embodiment comprises the following steps:

[0042] (1) Add 3.0 g of sodium hydride, 100 ml of DMSO and tetrahydrofuran to a 500 ml four-necked flask, stir and dissolve, and inject N 2For protection, add 15.7g of trimethylsulfoxide iodide in portions, control the temperature at 20°C, and keep stirring at this temperature for 2 hours; add the DMSO solution (30g+100ml) of telamycin oxide dropwise, and control the dropping temperature at -30°C, after the dropwise addition, keep it warm at -50°C for 1 hour, take a sample for detection, epoxy ketone isomer: epoxy compound = 90:10, add the reaction solution to 10% ammonium chloride aqueous solution, quench Reaction, the reaction solution was separated into layers, washed with brine, and then the organic phase was concentrated to dryness to obtain 31.4 g of the crude product of epoxy ketone isomers;

[0043] (2) The crude product of epoxy ketone isom...

Embodiment 3

[0048] The method for synthesizing and purifying telamycin impurity E of the present embodiment comprises the following steps:

[0049] (1) Add 3.0 g of sodium hydride, 100 ml of DMSO and tetrahydrofuran to a 500 ml four-necked flask, stir and dissolve, and inject N 2 For protection, add 15.7g of trimethylsulfoxide iodide in portions, control the temperature at 10°C, and keep stirring at this temperature for 2 hours; add the DMSO solution (30g+100ml) of telamycin oxide dropwise, and control the dropping temperature at 0°C, after the dropwise addition, keep it warm at -50°C for 1 hour, take a sample for detection, epoxy ketone isomer: epoxy compound = 90:10, add the reaction solution to 10% ammonium chloride aqueous solution, and quench the reaction , the reaction solution was layered, and after washing with brine, the organic phase was concentrated and dried to obtain 30.0 g of the crude product of epoxy ketone isomers;

[0050] (2) The crude product of epoxy ketone isomer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com