Patents

Literature

77 results about "Tulathromycin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

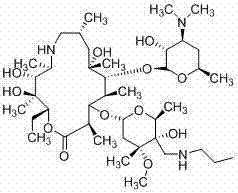

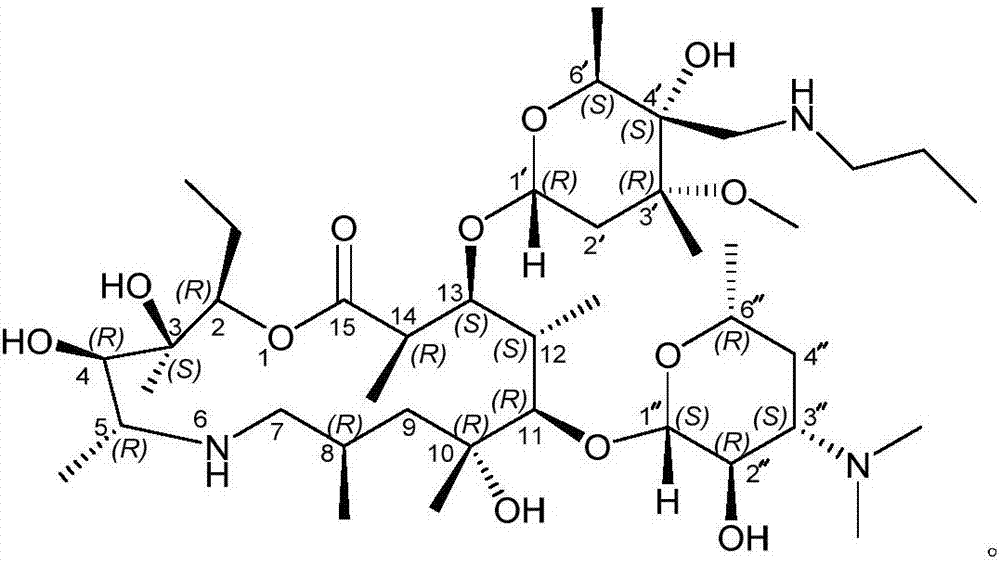

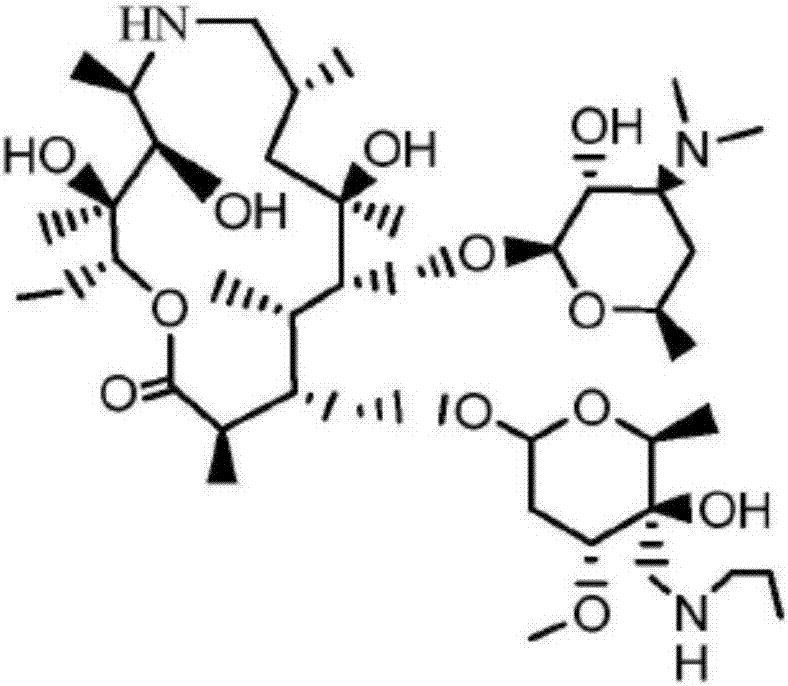

Tulathromycin is a macrolide antibiotic used to treat bovine respiratory disease (BRD) in cattle and swine respiratory disease in pigs. It is marketed by Pfizer Inc. under the tradename Draxxin. It is supplied as a solution for injection containing 100 mg of the drug.

Tulathromycin intermediate and preparation method thereof, as well as preparation method of tulathromycin

ActiveCN102786569AReduce manufacturing costMild conditionsSugar derivativesSugar derivatives preparationEpoxyTert-Butyloxycarbonyl protecting group

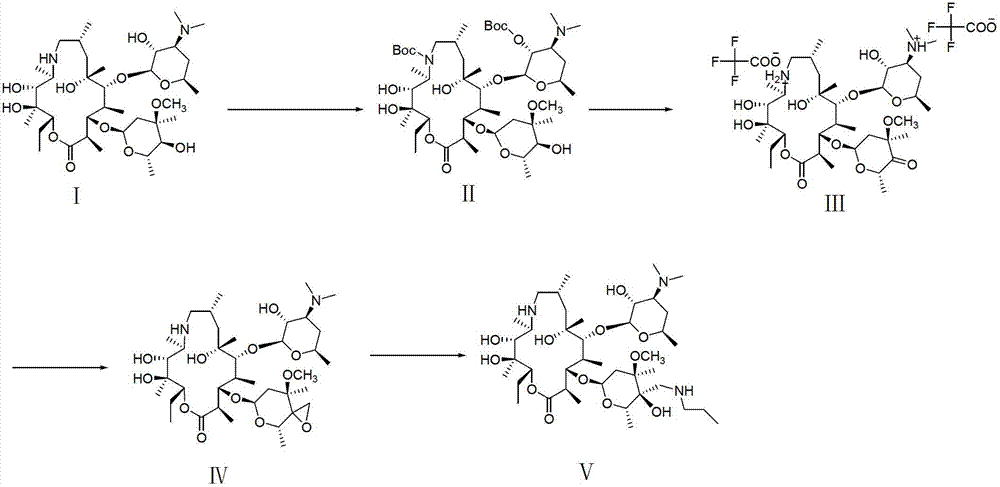

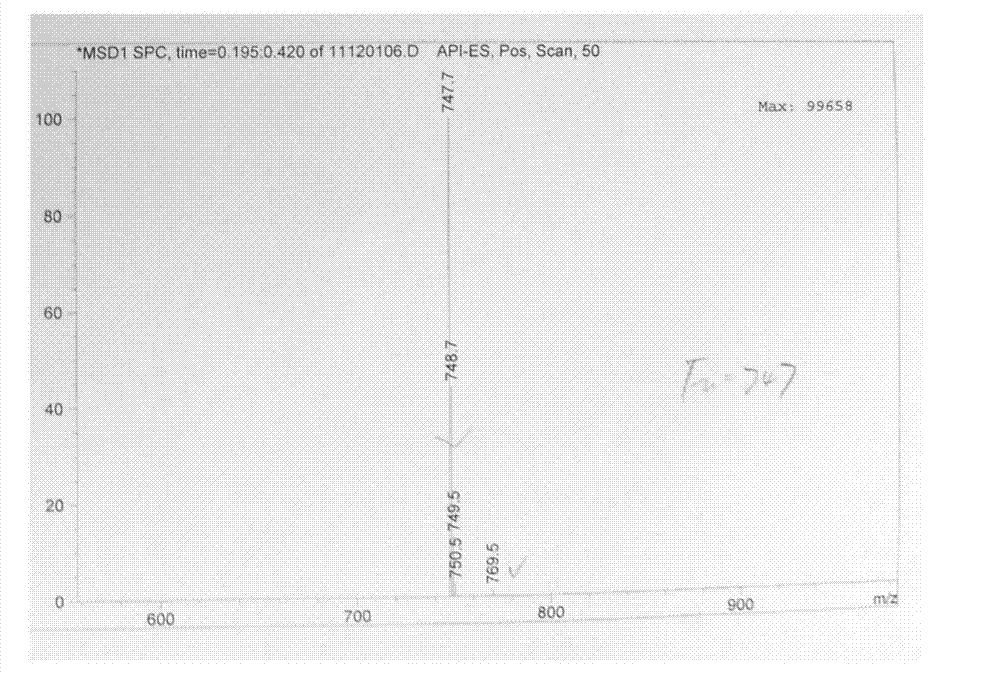

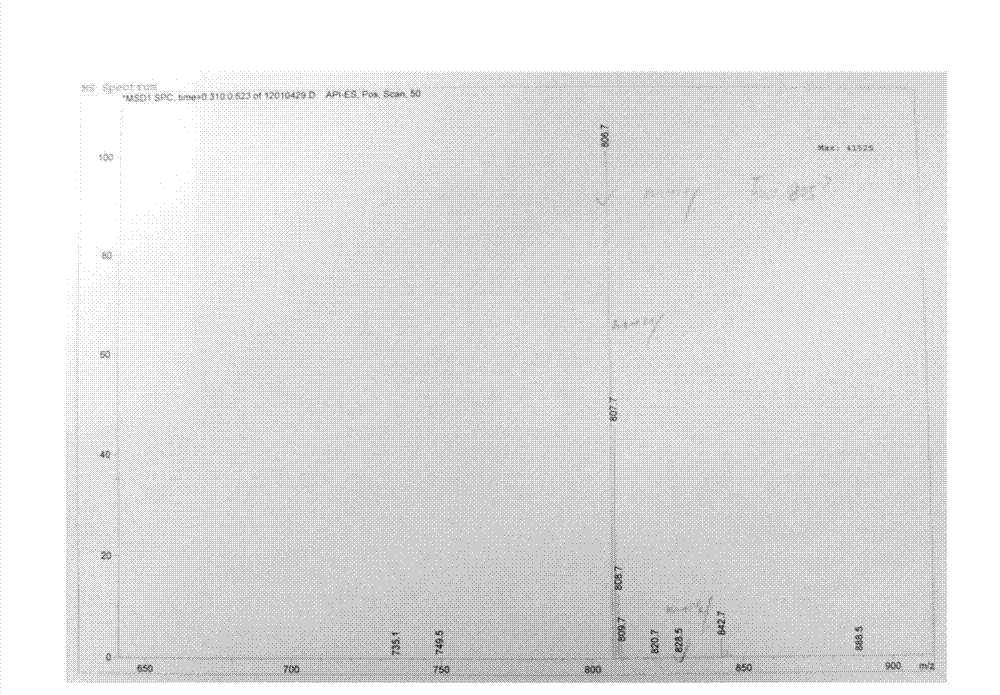

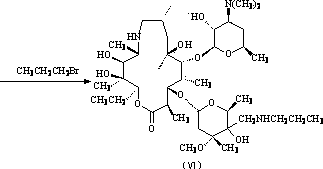

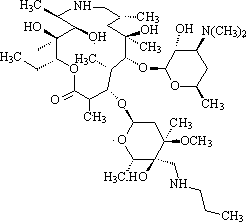

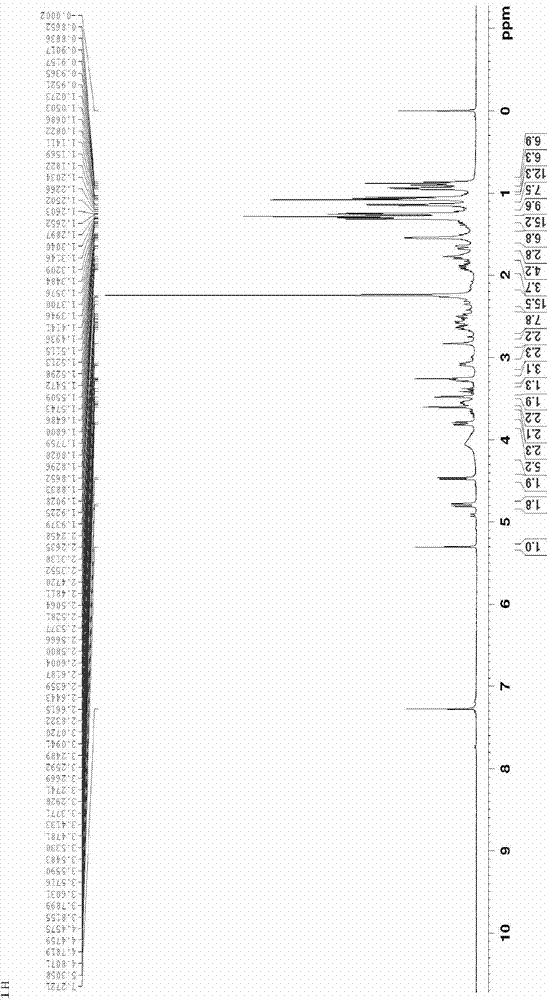

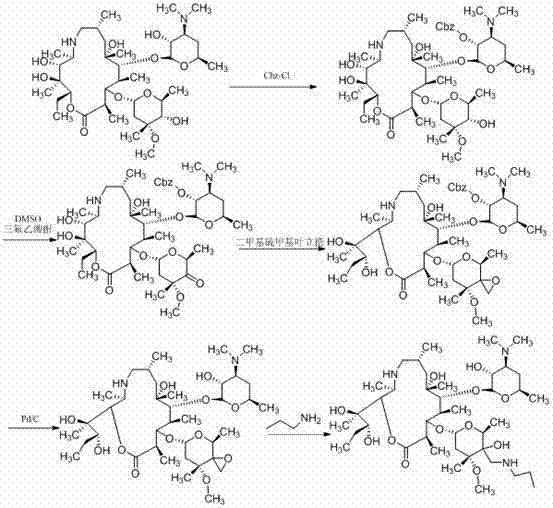

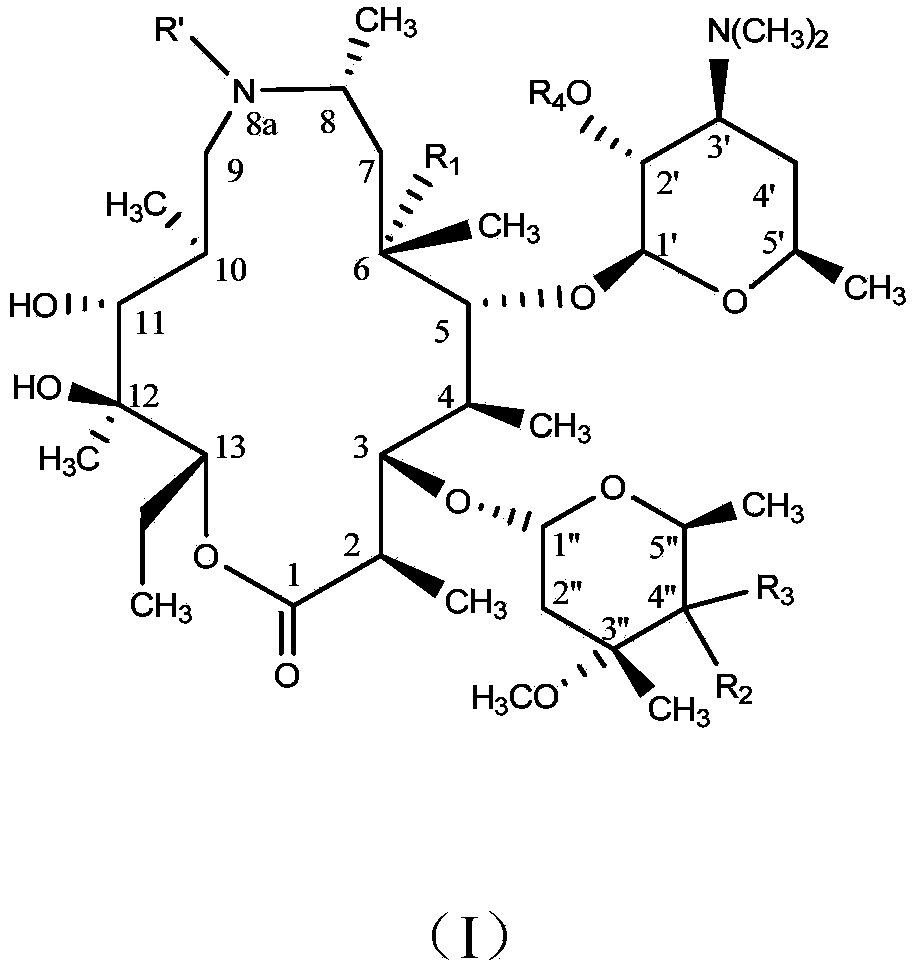

The invention provides a tulathromycin intermediate, a preparation method of the tulathromycin intermediate, and a preparation method of the tulathromycin. The preparation method of the tulathromycin has the advantages of mild condition, convenience for operation, and low cost. The preparation method of the tulathromycin comprises the following steps of: using azithromycin A as a raw material; protecting 2'-hydroxy and 6'-amino in the azithromycin A through di-tert-butyl dicarbonate so as to obtain double-protective azithromycin A; carrying out Swern oxidation to 4''-hydroxy to the double-protective azithromycin A; salifying along with trifluoroacetic acid; and synchronously removing boc t-butyloxycarbonyl to obtain the azithromycin A bitrifluoroacetic acid salt of 4''-carbonyl; and then reacting with trimethylsulfonium bromide to obtain 4''-epoxy compound; and finally carrying out nucleophilic addition on the 4''-epoxy compound by n-propylamine so as to obtain the phosphate of tulathromycin; and further neutralizing via alkaline to obtain the target compound tulathromycin; and synchronously obtaining the tulathromycin intermediate of azithromycin A bitrifluoroacetic acid salt of 4''-carbonyl.

Owner:TIANJIN ZHONGSHENG TIAOZHAN BIOTECH

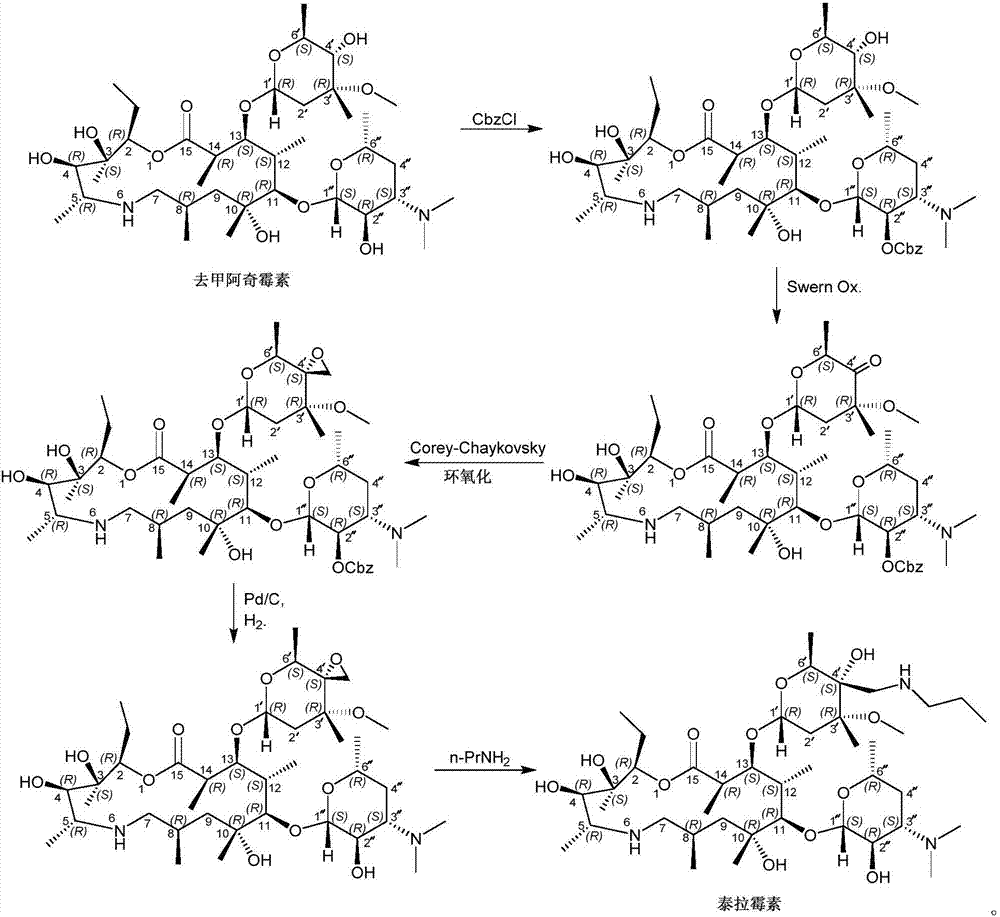

A new method for preparing telamycin

ActiveCN102260306AAvoid catalytic hydrogenation methodsReduce manufacturing costSugar derivativesSugar derivatives preparationEpoxyAzithromycin

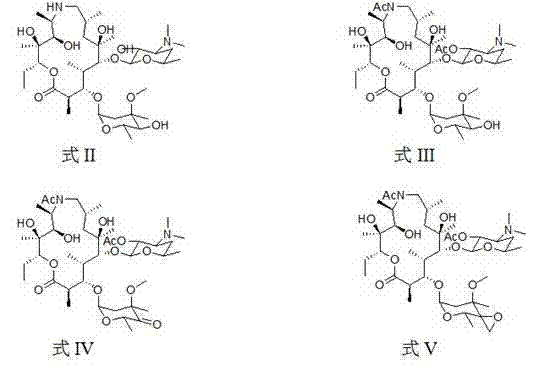

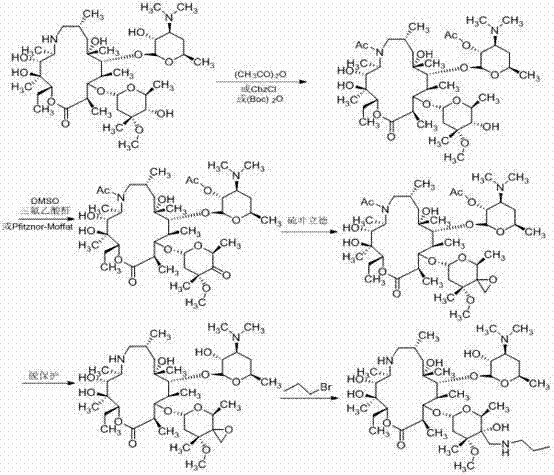

The invention discloses a novel method for preparing tulathromycin and relates to a semi-synthetic macrolide antibiotic. The method comprises the following steps: simultaneously protecting 2'-hydroxyl and 6a-amino of desmethyl azithromycin with acetyl, then carrying out oxidation and epoxidation on 4''-hydroxy, then removing the protecting groups under alkaline alcohol solution conditions, and carrying out nucleophilic addition on 4''-epoxy group with n-propylamine to obtain the target compound tulathromycin. Compared with the prior art, the method for preparing tulathromycin has the advantages of simple process, mild conditions, high yield and the like, and is beneficial to industrial production.

Owner:SHANDONG LUKANG SHELILE PHARMA

Method for preparing tulathromycin compound

The invention provides a method for preparing a tulathromycin compound. The method comprises the steps that: demethylated azithromycin is adopted as a raw material; and reactions such as substitution, oxidation, addition, reduction, condensation, and the like are carried out, such that a target compound is obtained. According to the invention, a cheaper raw material is adopted, and a traditional process employing low-temperature reaction is changed. The method has the advantages such as short process route, easy-to-control reaction, high yield, and the like. The method is suitable for large-scale industrialized productions.

Owner:QINGDAO VLAND BIOTECH INC

Oil injection containing tulathromycin/poloxamer 407

The invention discloses combination of tulathromycin and poloxamer 407. The technology comprises the following steps: preparing medicine-carrying micro-particles; further dispersing the medicine-carrying micro-particles into oil medium; and preparing a long-acting oil injection containing tulathromycin and poloxamer 407 medicine-carrying micro-particles in a grinding manner. The injection is simple in preparation technology, good in slow-release effect, good in biocompatibility, and free of an irreversible damage to the tissue of the injection part.

Owner:王玉万

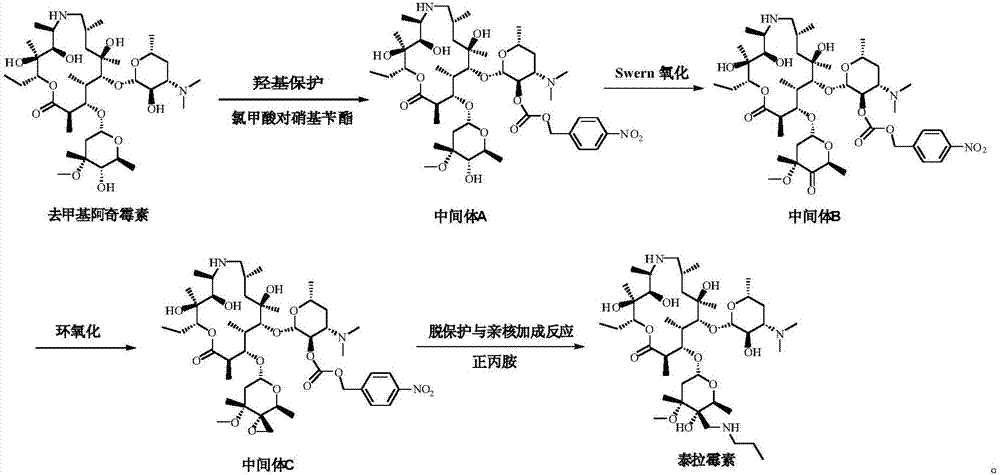

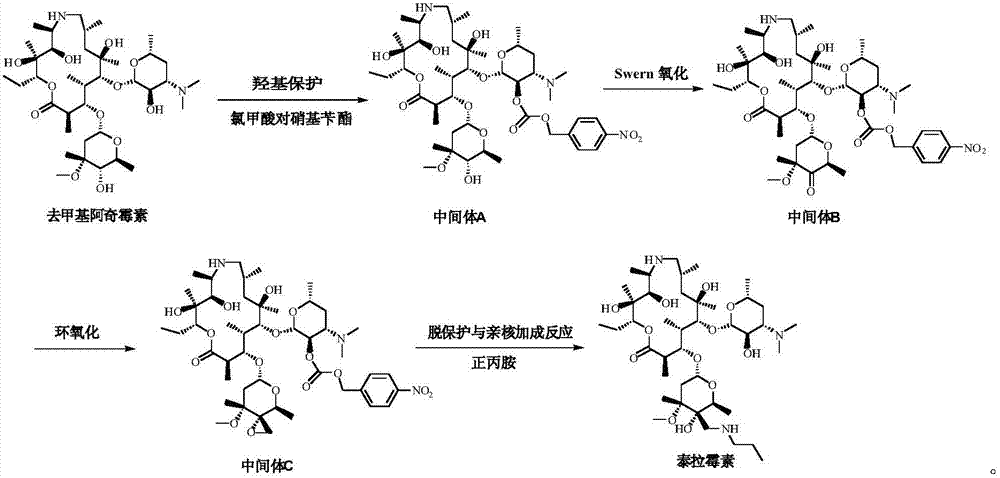

Preparation method of tulathromycin

ActiveCN106939029AImprove protectionAvoid catalytic hydrogenation methodsSugar derivativesSugar derivatives preparationAzithromycinChemical synthesis

The invention relates to the field of chemical synthesis and particularly relates to a preparation method of tulathromycin. The method comprises protecting a 2-hydroxyl group of demethyl azithromycin through 4-nitrobenzyl chloroformate, carrying out oxidation and epoxidation on a 4"-hydroxyl group, and carrying out deprotection and 4"-epoxy nucleophilic addition through n-propylamine to obtain tulathromycin. Comprised with the prior art, the preparation method has simple processes, mild conditions and a high yield, is free of palladium-carbon hydrodeprotection and is conducive to industrial production.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

Compound oral medicament composition for treating respiratory diseases of pig and cattle

The invention relates to a compound oral medicine composition for treating respiratory disease of animals, in particular to a compound oral medicine composition for treating the respiratory disease of pigs and cattle. The composition contains tulathromycin with effective quantity and nonsteroidal antipyretic and analgesic.

Owner:QINGDAO VLAND BIOTECH INC

A synthetic method of high-purity tulathromycin

InactiveCN103864865ASugar derivativesSugar derivatives preparationAzithromycinBiochemical engineering

The invention provides a synthetic method of high-purity tulathromycin. The method includes subjecting demethylated azithromycin adopted as a raw material to substitution, oxidation, addition, reduction, condensation, and the like, so as to obtain a target compound. According to the synthetic method, the cheaper raw material is adopted, and a traditional process employing low-temperature reaction is changed. The method has the advantages of short process route, easy-to-control reaction, high yield, and the like. The method is suitable for large-scale industrialized production.

Owner:QINGDAO VLAND BIOTECH INC

Preparation method for tulathromycin intermediate

InactiveCN103497227ASuitable for industrial productionSugar derivativesSugar derivatives preparationAcetic anhydridePtru catalyst

The invention relates to a preparation method for a tulathromycin intermediate. The preparation method comprises the following steps: oxidizing 4'-hydroxyl of demethylazithromycin of which the hydroxyl is protected by acetyl under a mild condition to obtain ketone by using a dimethyl sulfoxide and acetic anhydride system, and continuing to epoxidize the obtained ketone to obtain an epoxide by using a phase transfer catalyst, wherein the intermediate epoxide of tulathromycin can be introduced into propylamine through an open loop, and is subjected to deprotection to obtain the tulathromycin. According to the reaction method, a phase transfer catalyst system is adopted for the first time in an exoxidizing process, reaction conditions are mild, and the method is high in yield and more suitable for industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

Tulathromycin composition and use thereof in preparation of drugs for treating or preventing bacterial diseases of poultry

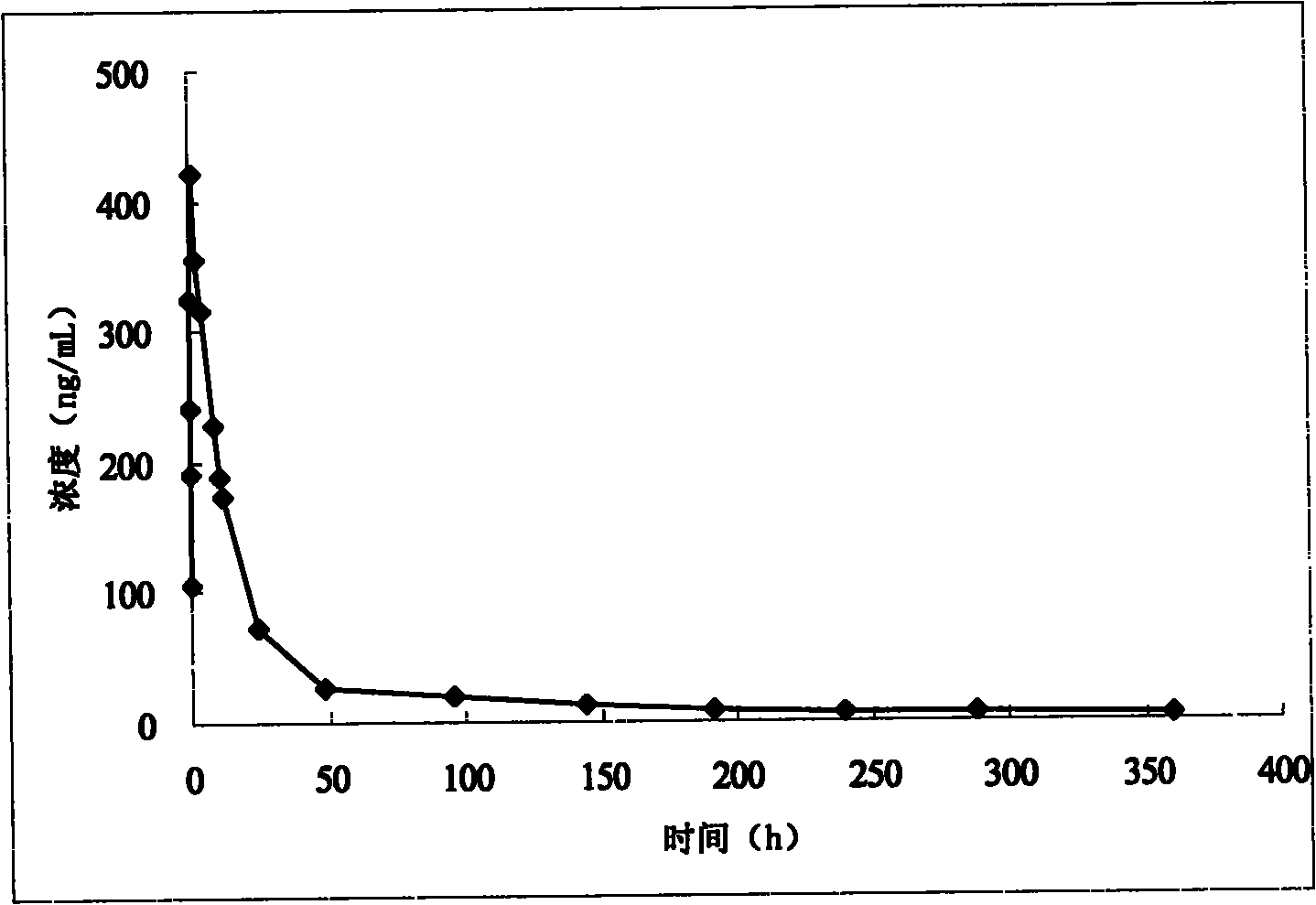

InactiveCN101933935AWidely distributedApparent volume of distribution is largeAntibacterial agentsOrganic active ingredientsMedicineHalf-life

The invention discloses an application of a tulathromycin composition in treatment or prevention of bacterial diseases of poultry. The invention further discloses a pharmaceutical composition containing tulathromycin and a preparation method thereof, and the composition has wide distribution in a poultry body, large apparent distribution volume, long half-life period and slow elimination, has the characteristics of small dosage and good efficacy when being used for treating the bacterial diseases of the poultry, and further has broad market prospects and value when being applied in the preparation of the drugs which are widely clinically used in veterinary.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

Tulathromycin intermediate, preparation method of tulathromycin intermediate and preparation method of tulathromycin

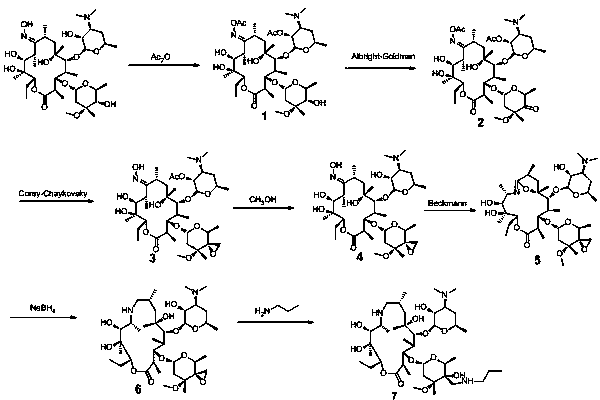

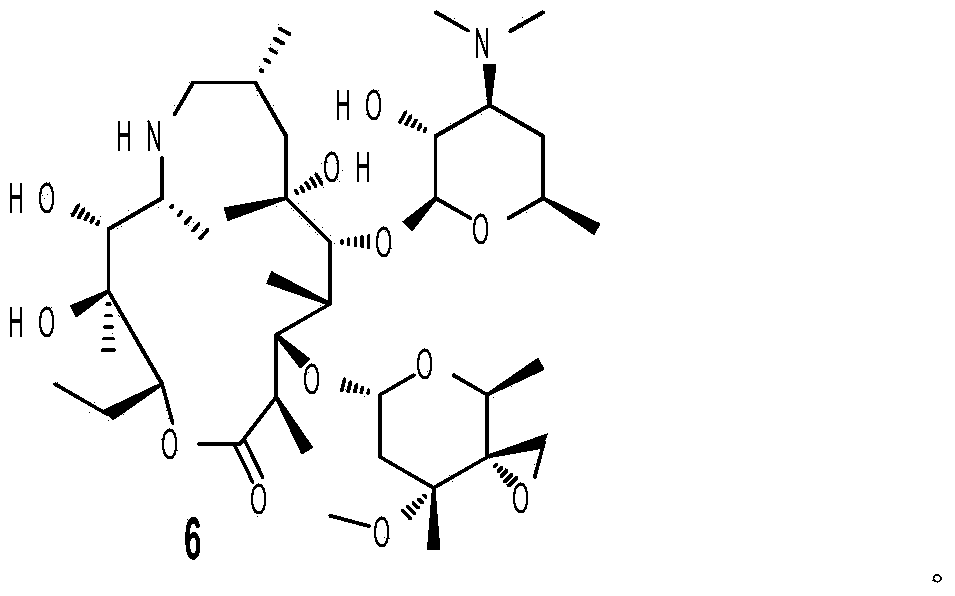

InactiveCN103772459AAvoid residueSimple and safe operationSugar derivativesSugar derivatives preparationBeckmann rearrangementHydrolysis

The invention provides a tulathromycin intermediate, a preparation method of the tulathromycin intermediate and a preparation method of tulathromycin. According to the preparation method, Erythromycin A (E) oxime used as a starting material is subjected to acetyl protection, Albright-Goldman oxidation, Corey-Chaykovsky epoxidation, deprotection, Beckmann rearrangement, reduction and hydrolysis, and n-propylamine ring opening to synthesize tulathromycin. The preparation method has mild conditions, has the advantages of convenient operation, high yield and low cost and is beneficial to industrial production, and the raw materials are easily available.

Owner:QINGDAO VLAND BIOTECH INC

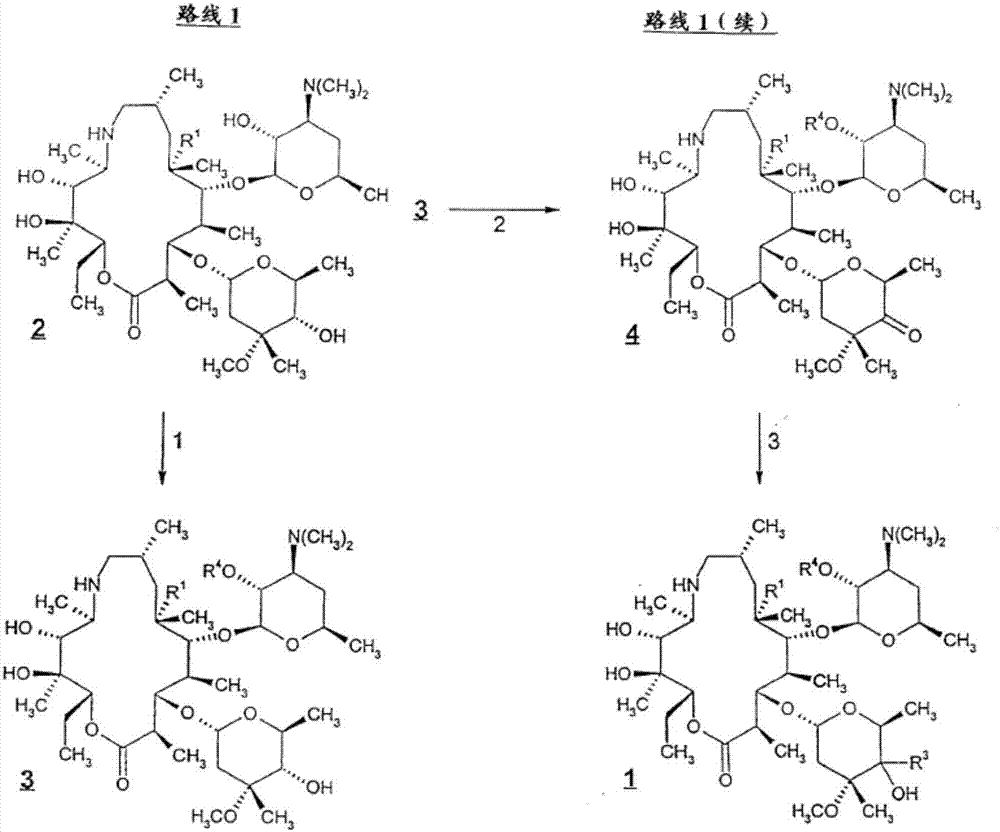

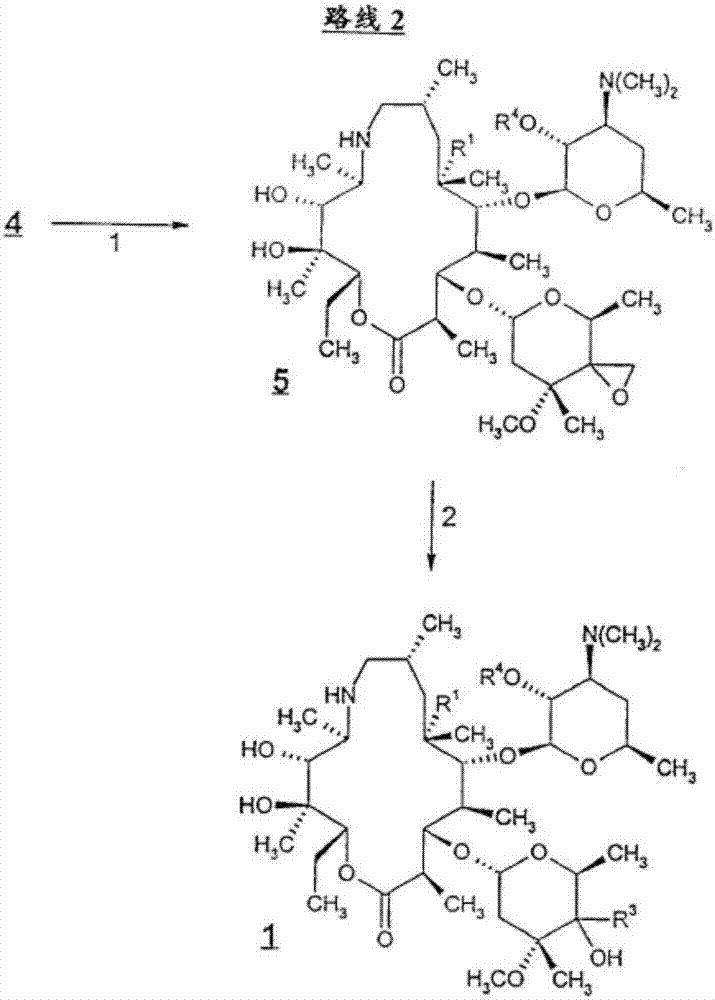

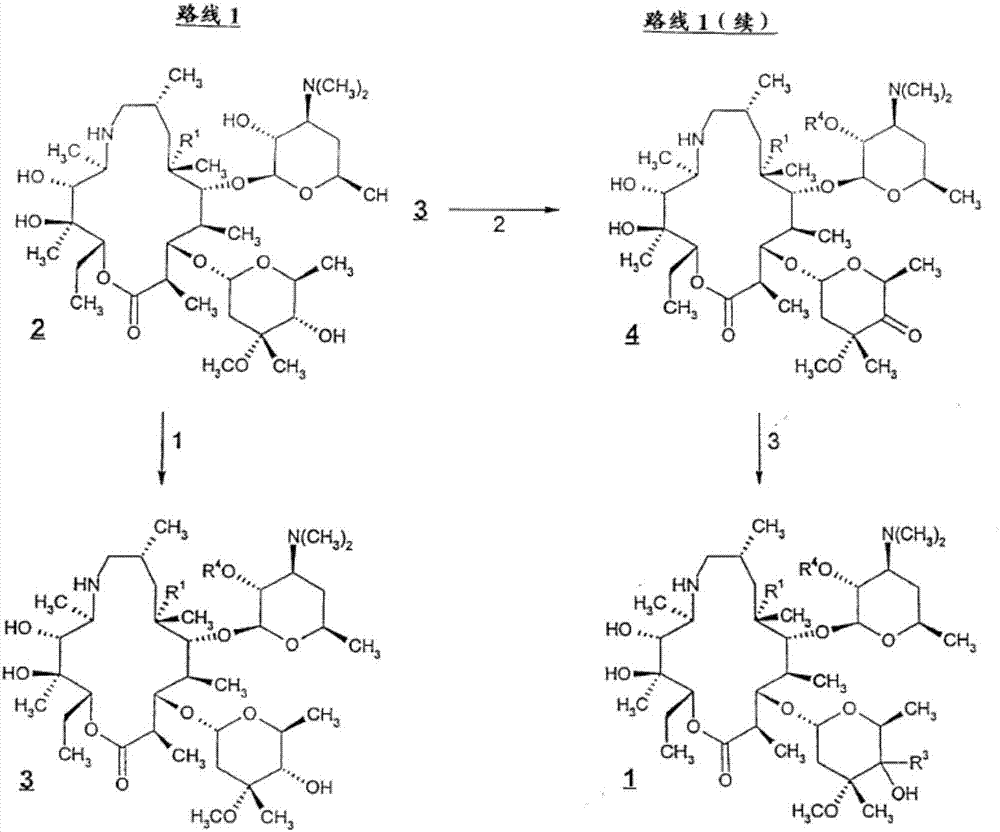

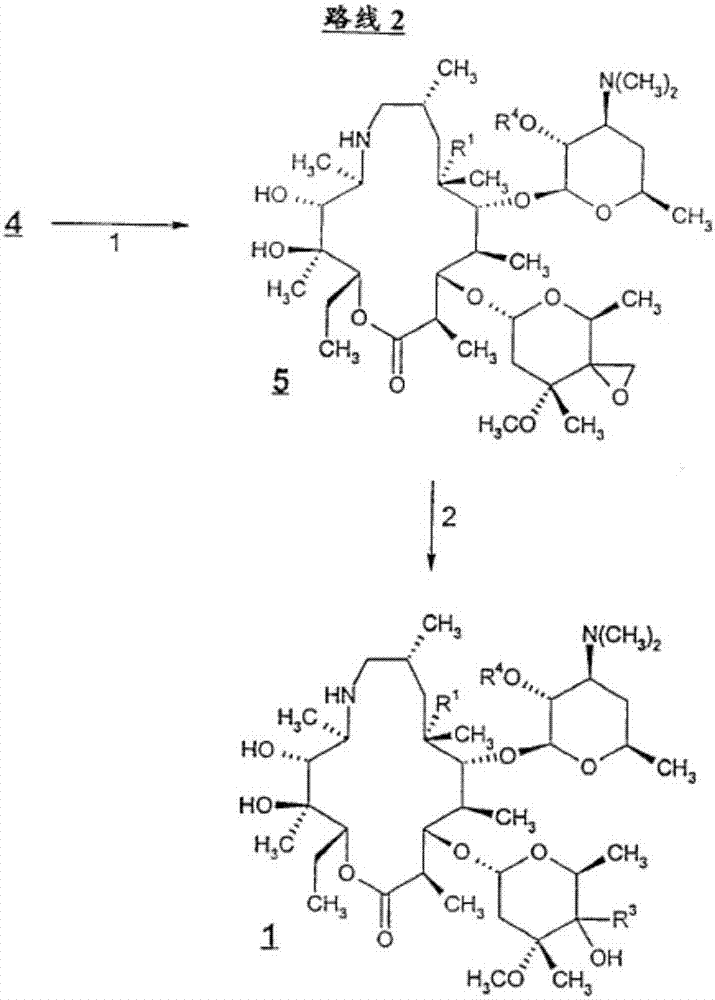

Tulathromycin A synthesis method

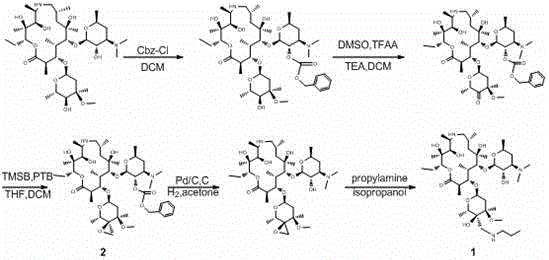

ActiveCN106046077AReduce usageAvoid hydrogenation reactionsSugar derivativesSugar derivatives preparationSynthesis methodsPropylamine

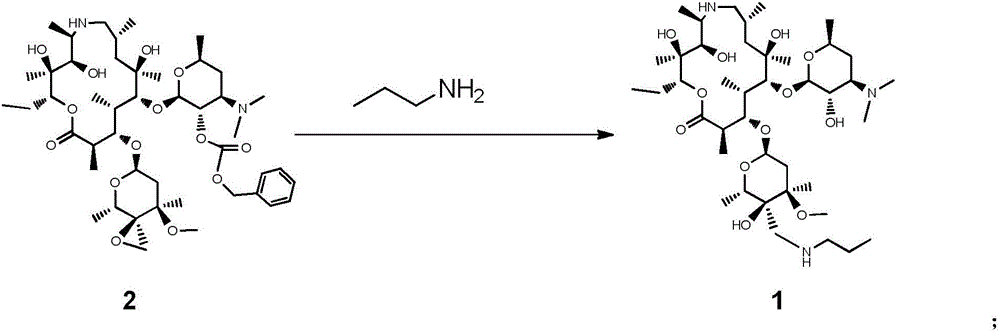

The invention discloses a tulathromycin A synthesis method and belongs to the technical field of medicine synthesis. The tulathromycin A synthesis method comprises 1, dissolving a compound 2 into a solvent 1 and carrying out a reaction process on n-propylamine at a temperature of 20-80 DEG C, 2, after the reaction, according to reaction product benzyloxycarbonyl removal cases, directly carrying out a reaction process at a temperature of 20-80 DEG C, or adding a deprotection regent into the reaction product and then carrying out a reaction process on the mixture at a temperature of 20-80 DEG C, and separating the reaction products to obtain a tulathromycin A crude product, and 3, purifying the tulathromycin A crude product to obtain a tulathromycin A refined product. The tulathromycin A synthesis method realizes deepoxidation and deprotection by one process, shortens reaction time, improves reaction efficiency and reduces a cost.

Owner:MASTEAM BIO TECH

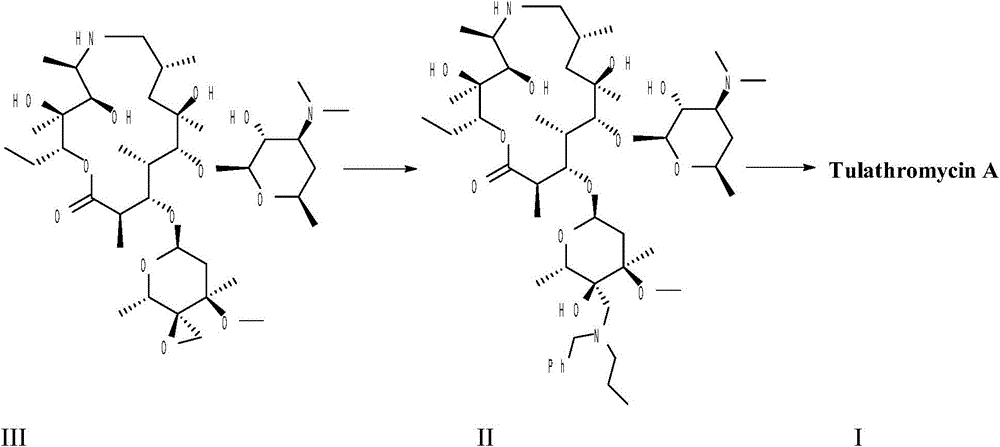

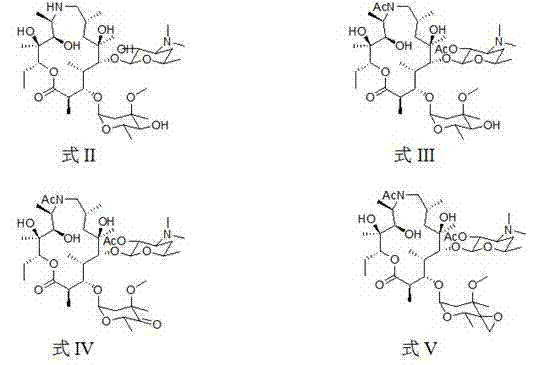

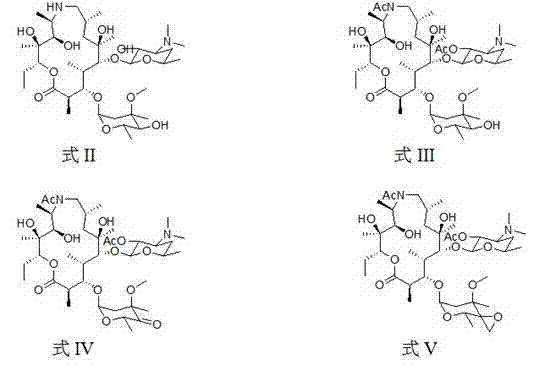

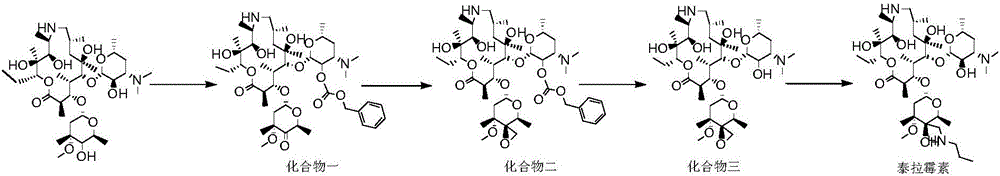

New route for synthesizing tulathromycin

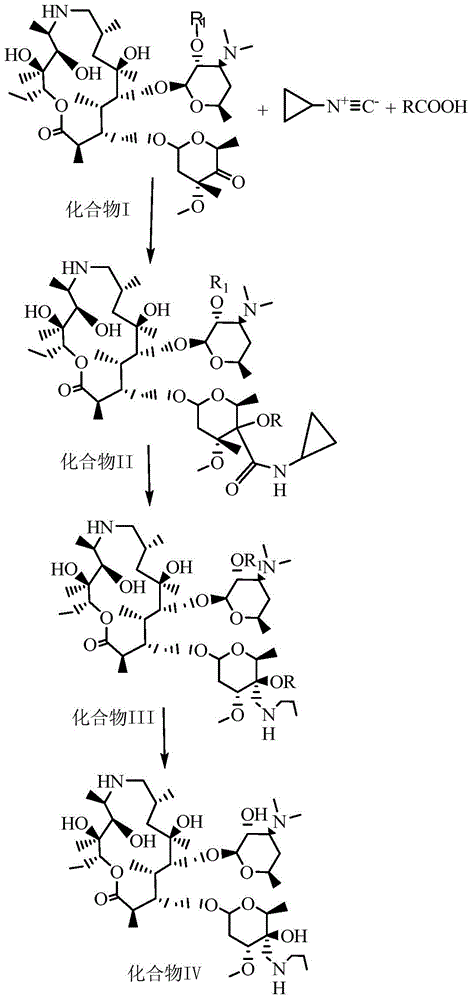

ActiveCN104876983AThe reaction process is simpleEasy to implementSugar derivativesSugar derivatives preparationPasserini reactionAzithromycin

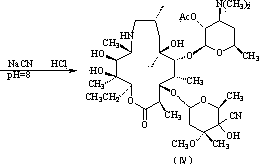

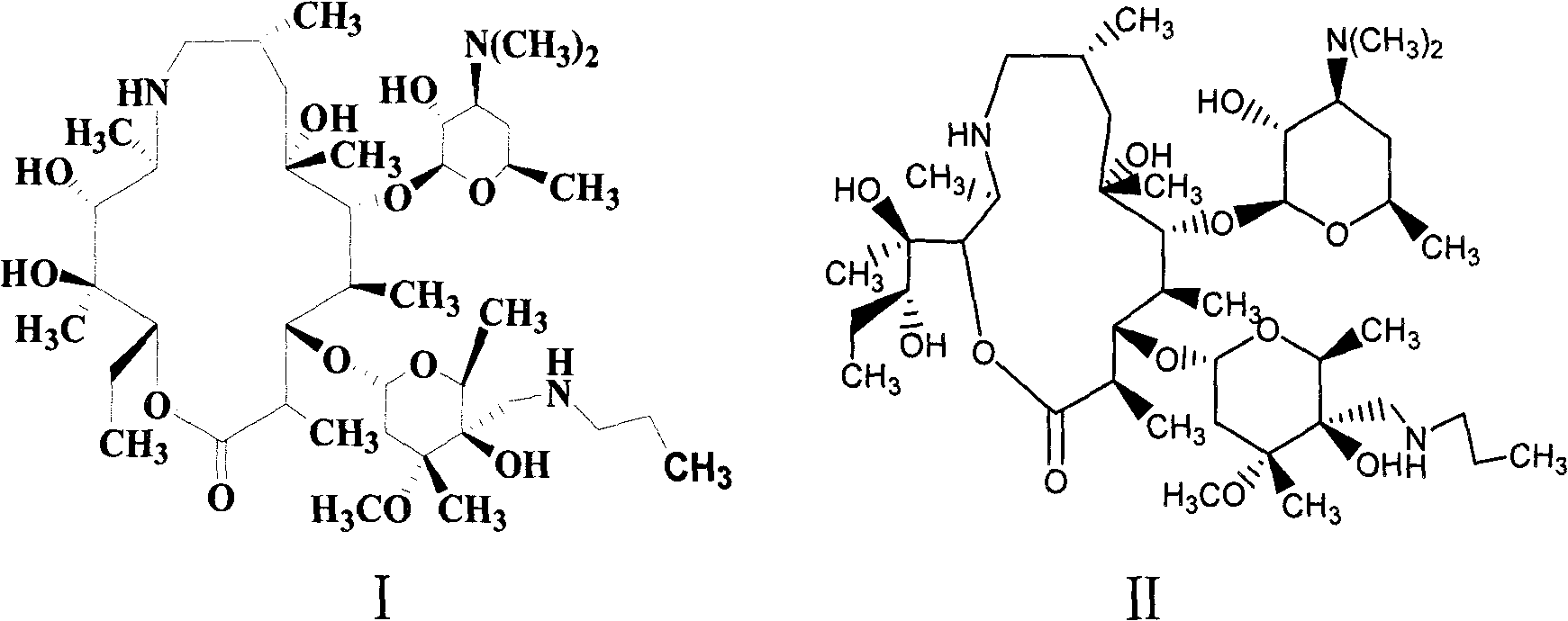

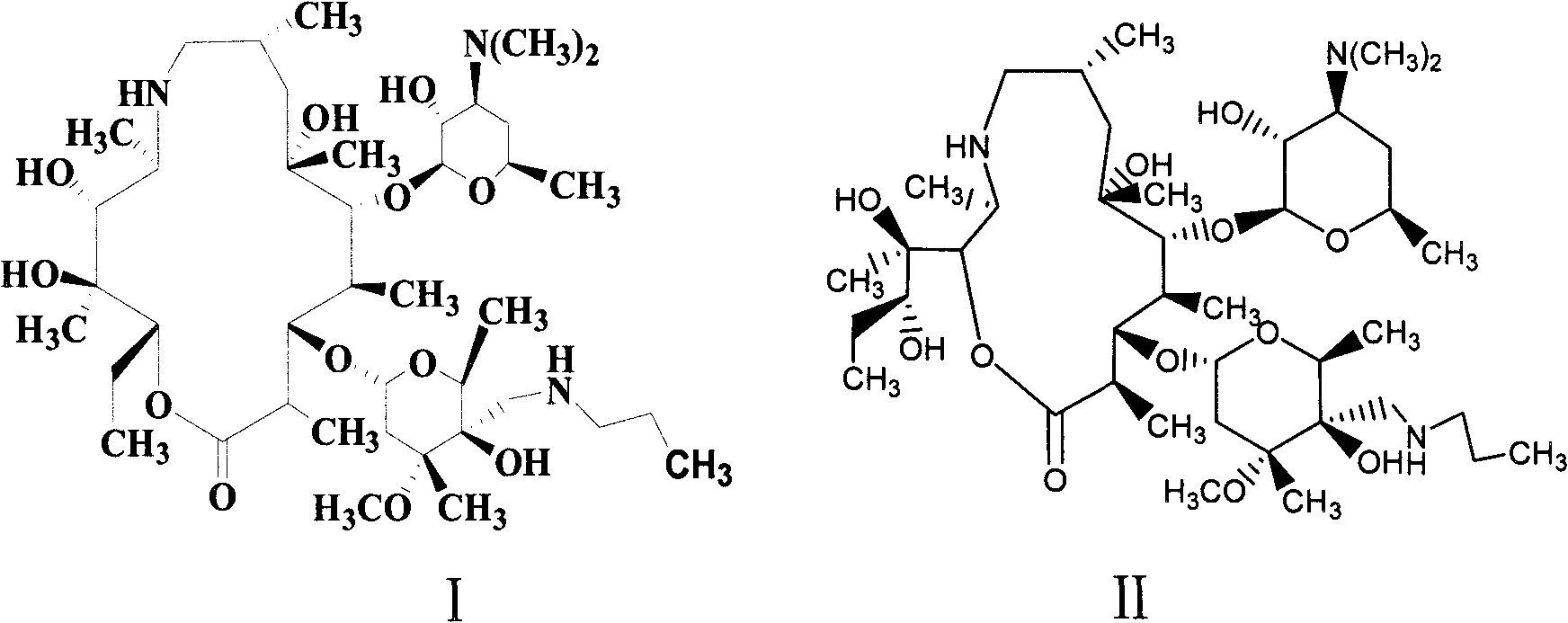

The invention discloses a new route for synthesizing tulathromycin. The new route for synthesizing the tulathromycin is different from the previous epoxidation reaction, ring-opening reaction and the like reaction process. The new route for synthesizing the tulathromycin uses Passerini reaction, all the groups are led in by one time, and then the tulathromycin is obtained through Clemmensen reaction and hydrogenation reduction reaction. The new route for synthesizing the tulathromycin includes steps that taking hydroxyl protecting demethylation azithromycin, generating hydroxyl protecting ketone (compound I) through oxidation reaction, leading amido bond and cyclopropyl to a ketone-hydroxyl group position, generating (compound II), reducing the hydroxyl into methylene through Clemmensen reaction, generating (compound III), carrying out hydrogenation and ring opening on cyclopropyl to generate n-propyl through ring-opening reaction, and obtaining the tulathromycin (compound IV). The new route for synthesizing the tulathromycin is simple in process, easy to implement, easy to obtain reaction reagent, moderate in reaction condition, high in selectivity, less in by-product, easy to purify and low in facility request.

Owner:RINGPU TIANJIN BIOLOGICAL PHARMA

Method for preparing tulathromycin compound by taking demethylated azithromycin as raw material

InactiveCN104193789AHigh antibacterial activityBroad spectrum antibacterialSugar derivativesSugar derivatives preparationAzithromycinHalf-life

The invention discloses a method for preparing tulathromycin compound by taking demethylated azithromycin as a raw material. The preparation method comprises the following steps: by taking the demethylated azithromycin as a raw material, performing substitution, oxidation, addition, reduction and condensation reactions, thereby obtaining a target compound. The method has the advantages that the compound is high in antibacterial activity and wide in antibacterial spectrum and has ultra-long half-life period, the whole treatment process is finished by single-dose, and the like.

Owner:苏赵珍

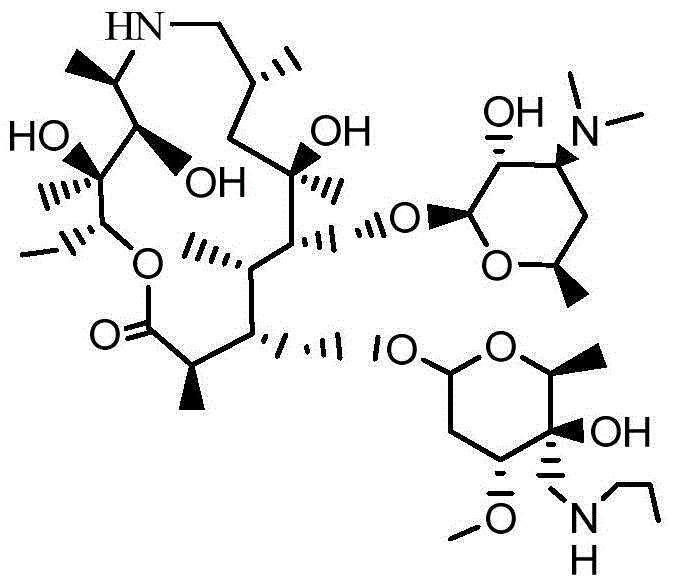

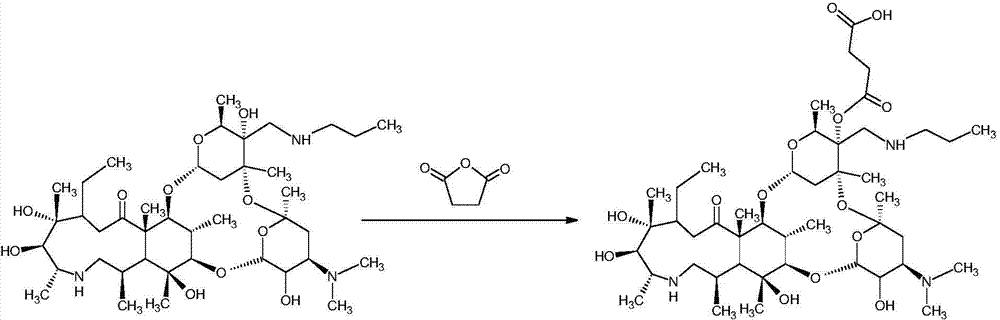

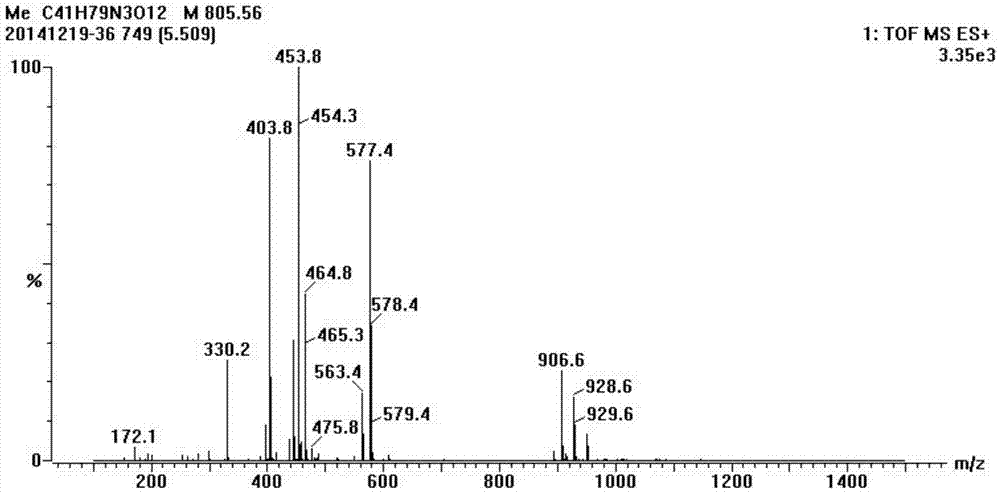

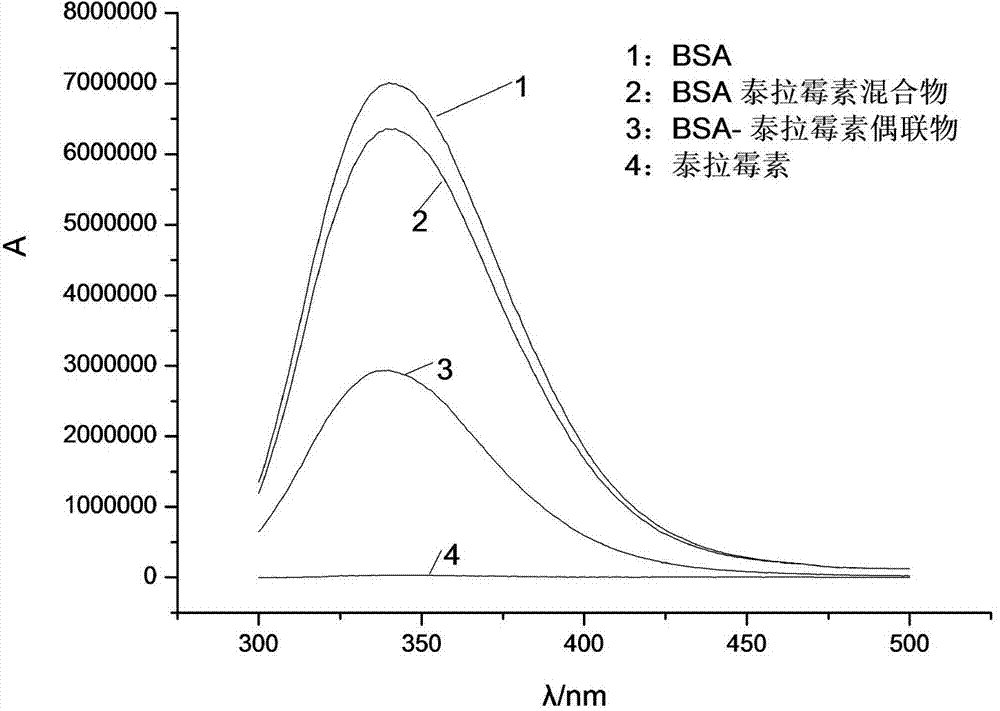

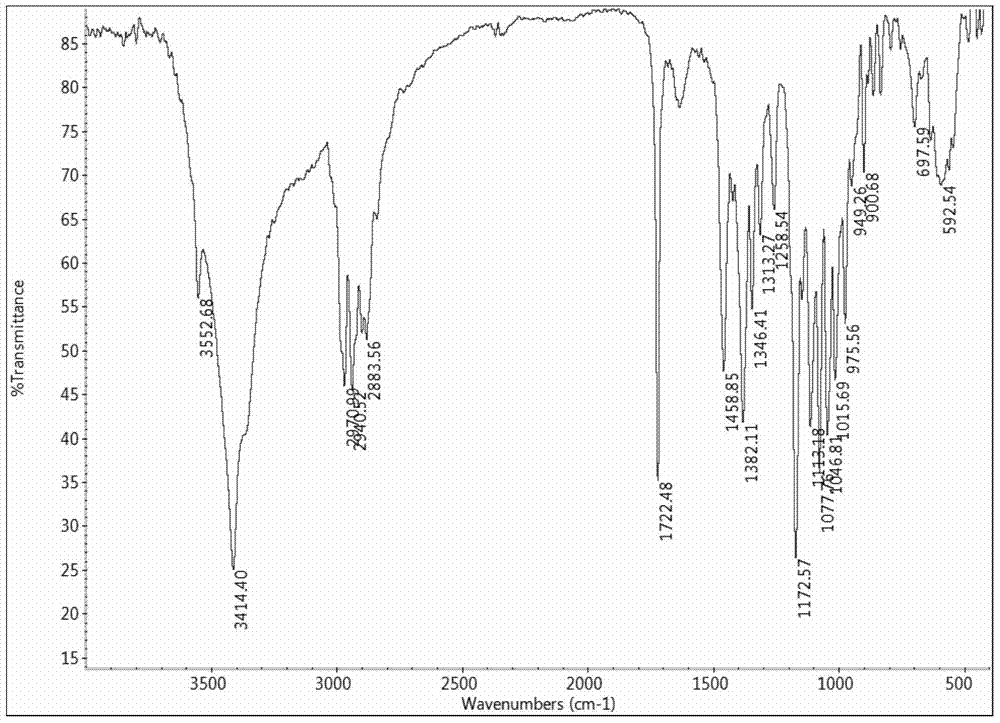

Synthesis method of half-antigen and complete antigen of tulathromycin

The invention discloses a synthesis method of a half-antigen and a complete antigen of tulathromycin and belongs to the technical field of immunology. The method synthesizes the half-antigen of tulathromycin by carrying out hydroxyl on tulathromycin by a succinic anhydride method and introducing free carboxyl. Derivated free carboxyl reacts with primaquine of bovine serum albumin to form an amido bond for coupling by an active ester method to form the complete antigen of tulathromycin. After the antigens are used for immunizing a Balb / c mouse for three times, the valence can reach 1:8000. The antigens have wide practical application prospects.

Owner:JIANGNAN UNIV

Method for preparing tulathromycin soluble powder

The invention relates to tulathromycin soluble powder used for treating chicken Escherichia coli disease. A preparation method comprises the steps that: a tulathromycin salt compound is well mixed with a carrier; the mixture is crushed and sieved by using a 80-mesh sieve, such that a product is obtained.

Owner:QINGDAO VLAND BIOTECH INC

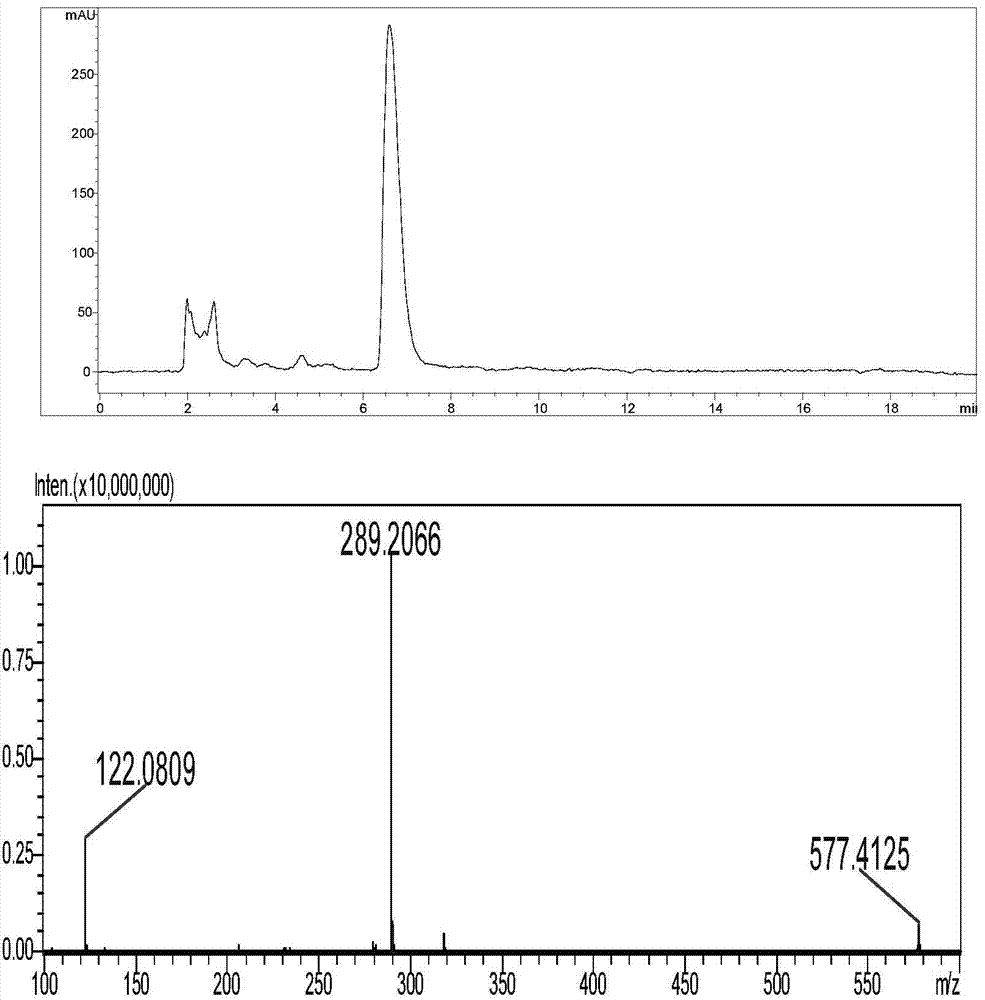

Synthesis method of tulathromycin residue marker

InactiveCN104119413ARaw materials are cheap and easy to getMild reaction conditionsSugar derivativesSugar derivatives preparationChemical synthesisBeckmann rearrangement

The invention belongs to the technical field of chemical synthesis, particularly a chemical synthesis method of a tulathromycin residue marker named 3-decladinosyl-9-deoxy-9-dihydro-9a-aza-9a-homoerythromycin A. The method is characterized by comprising the following steps: carrying out Beckmann rearrangement reaction on the raw material erythromycin A (E) oxime to obtain erythromycin A 6,9-imino ether, reducing with sodium borohydride to obtain nitroerythromycin, hydrolyzing under acidic conditions to remove cladinose to obtain a 3-decladinosyl-9-deoxy-9-dihydro-9a-aza-9a-homoerythromycin A crude product, and repeatedly recrystallizing to obtain the pure product of which the HPLC (high performance liquid chromatography) purity is up to higher than 99.5%. The method has the advantages of simple technique and high reaction yield. The product has high purity and can be used as a standard substance candidate of the tulathromycin residue marker.

Owner:HUAZHONG AGRI UNIV

Tulathromycin liposome and preparation method thereof

The invention belongs to the technical field of pharmacy, and provides a tulathromycin liposome which comprises tulathromycin and a lipid material; the lipid material comprises phospholipid, and the weight ratio of the tulathromycin to the phospholipid is 1:1-20. The invention also provides a corresponding preparation method which comprises the following steps: 1) dissolving the lipid material in ethanol, and preparing a blank liposome suspension by a film dispersion method, an injection method, a reverse evaporation method, or a spray-drying method; 2) preparing gradient liposome; 3) adding an ethanol solution of tulathromycin, controlling the ethanol content of the system to be less than 15 V%, performing incubation at 45-75 DEG C for 2-60 min to obtain a tulathromycin-containing liposome suspension. Liposome is encapsulated by tulathromycin, which effectively improves the bioavailability of tulathromycin. The ethanol content is controlled in the preparation method, which contributes to the acquisition of higher encapsulation efficiency and appropriate particle size.

Owner:HENAN SOAR VETERINARY PHARMA

Preparation method of azalide type tulathromvcin injection

InactiveCN101416977AReduce the number of medicationsReduce stress responseAntibacterial agentsOrganic active ingredientsWater useAzalide

The invention relates to a preparation method of an injection containing azalide tulathromycin; the injection consists of tulathromycin, hydrochloric acid, propylene glycol, phenol and water used for injection. The preparation method comprises the steps of: adding a proper amount of the water used for injection into a stainless-steel liquid distributing tank, adding 5100g of a 10-percent (w / w) hydrochloric-acid water solution and stirring the solution evenly, slowly adding 104g to 208g of the tulathromycin into the solution, stirring the solution till the tulathromycin is dissolved, adding the 10-percent (w / w) hydrochloric-acid water solution to adjust the pH value to be 4.0 to 7.0, heating the solution to the temperature of 60 DEG C to 70 DEG C for 10min to 30min, adding and evenly stirring 500g of propylene glycol (a cosolvent) when the temperature reaches 25 DEG C, adding the 10-percent (w / w) hydrochloric-acid water solution to regulate the pH value to reach 5.4, adding 5g to 10g of the phenol as a preservative, adding the water used for injection till the total volume of the solution is adjusted to be 1000ml, filtering the solution by a 5-to-10-micron filter and a 0.45-micron filter in sequence, encapsulating the filtered preparation and sterilizing the preparation by a wet-heat high-pressure sterilizing method for 30min at the temperature of 121 DEG C.

Owner:PU LIKE BIO ENG

Preparation method of animal antibiotic tulathromycin

ActiveCN103588833AHigh purityAvoid Pd/CSugar derivativesSugar derivatives preparationBiotechnologyAcetic anhydride

The invention belongs to the technical field of organic synthesis and pharmaceutical chemistry and especially relates to a preparation method of an animal antibiotic tulathromycin. According to the preparation method, azithromycin A and acetic anhydride which are used as raw materials are subjected to protection and oxidation to obtain oxide cyclic ketone; the intermediate is used for innovative addition of cyclic ketone and nitromethane; an addition product is reduced to obtain methyleneamine; direct condensation between methyleneamine and propionaldehyde is carried out; and reduction is conducted to obtain the high-purity target compound. Raw materials which are cheap and easily available are adopted. The preparation method has advantages of simple reaction, easily-controlled reaction process, high product purity, manageability, high yield, low cost and the like, and is suitable for large-scale industrial production.

Owner:UNIV OF SCI & TECH BEIJING

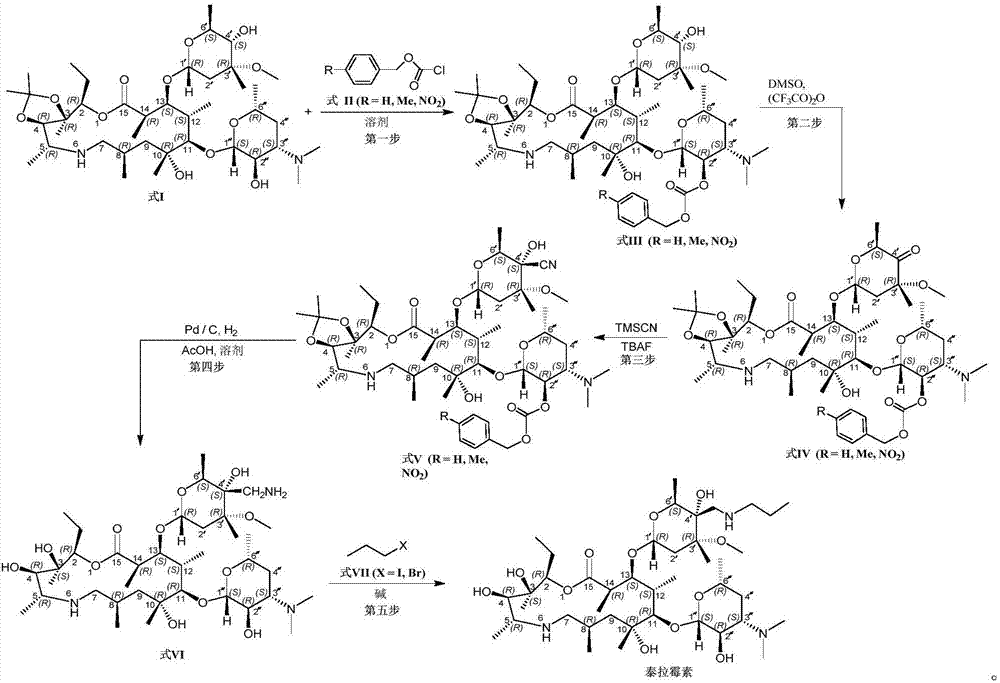

Method for preparing tulathromycin

ActiveCN108003207AInhibit side effectsGood choiceSugar derivativesSugar derivatives preparationHydrogenation reactionProtecting group

The invention relates to a novel method for preparing tulathromycin. The method includes the steps that 3,4-acetonylidene protected demethylazithromycin is used as a starting material, a 2-hydroxyl group is firstly protected, then a 4-hydroxyl group is oxidized to a carbonyl group under Swern conditions, TMSCN is used for performing a cyano group addition reaction on the carbonyl group under the action of TBAF, a resulting intermediate compound is subjected to a hydrogenation reaction in the presence of HOAc with Pd / C as a catalyst, the cyano group in the compound is converted into an amine methyl group while a 2-hydroxy group protecting group and 3,4-acetonylidene protection are removed, and finally under the action of base, an amine methyl compound is reacted with 1-halogenated propane to achieve the preparation of tulathromycin.

Owner:WISDOM PHARM CO LTD

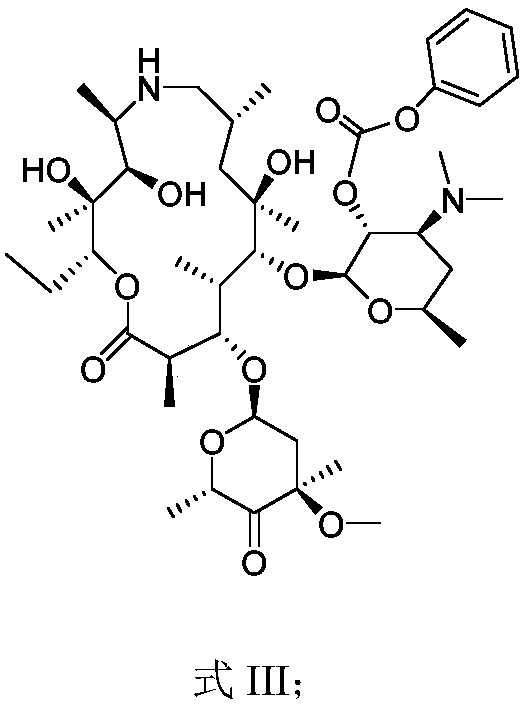

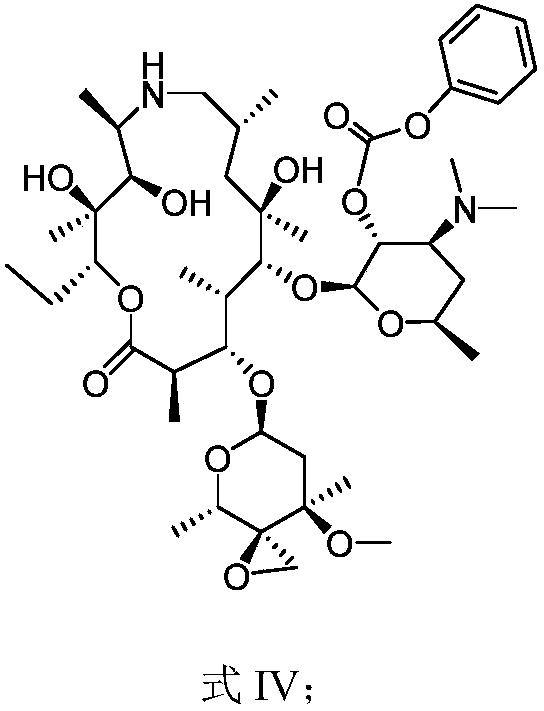

Preparation method of tulathromycin

InactiveCN110903335AHigh purityHigh yieldSugar derivativesSugar derivatives preparationAzithromycinMedicine

The invention provides a preparation method of tulathromycin, and belongs to the field of pharmaceutical chemicals. The method comprises the following steps of: reacting azithromycin serving as a rawmaterial with phenyl chloroformate to protect hydroxyl to obtain protected nitrogen azithromycin, oxidizing the hydroxyl into a ketone group by oxidation, epoxidizing, deprotecting, and reacting withn-propylamine to obtain tulathromycin. The product produced by the method has the characteristics of high purity, high yield, low cost, simple operation and stable process.

Owner:SUNSHINE LAKE PHARM CO LTD

Method for preparing tulathromycin

InactiveCN105646617AGuaranteed spatial selectivityCrude product of good qualitySugar derivativesChemical recyclingPalladium on carbonPhosphate

The invention relates to large-loop type veterinary medicine antibiotics, in particular to a method for preparing tulathromycin. The method mainly solves the problem that in the prior art, the dosage of n-propylamine is large, and also solves the technical problems that due to the large dosage of n-propylamine, a crude product is not high in content and poor in character, and phosphate needs to be formed, neutralized and purified. The method comprises the steps that an epoxy intermediate, ethyl alcohol or isopropanol and N-benzyl propylamine are added into a reactor and stirred fully and evenly, and then heating and stirring are carried out for a reaction; after the reaction is finished, a solvent is removed, acetone is added, and the mixture is evenly stirred and then transferred into a pressure reactor; a palladium carbon catalyst is added in the pressure reactor, hydrogen is introduced, a reaction is carried out under stirring, the catalyst is recycled through filtering after the reaction is finished, concentration is carried out to remove the solvent, then water is added, filtering is carried out, separated-out solids are collected and subjected to vacuum drying, a tulathromycin crude product is obtained, and a fine tulathromycin product is obtained after recrystallization.

Owner:杭州海尔希畜牧科技有限公司

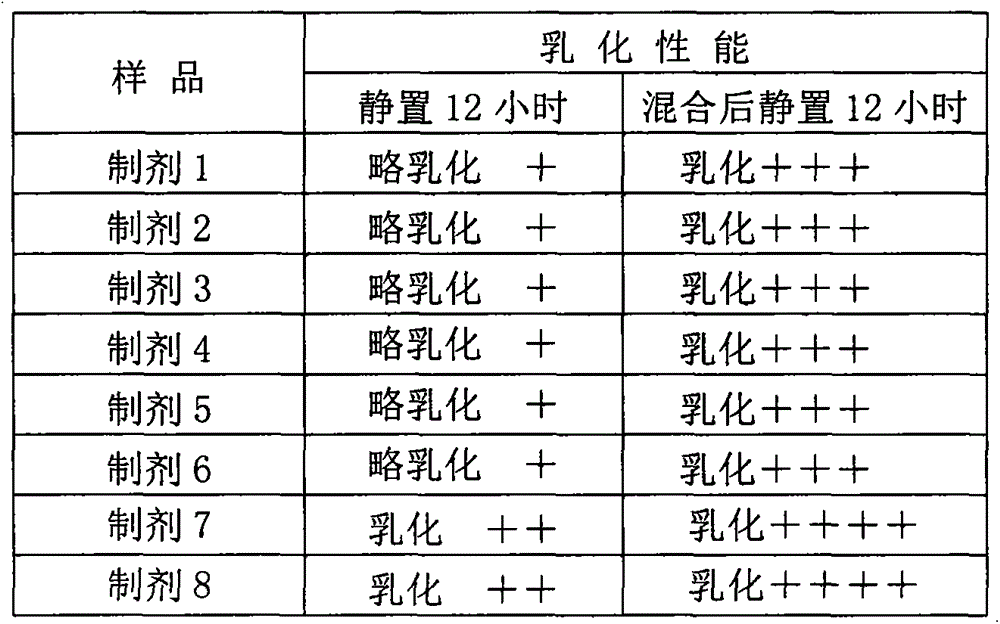

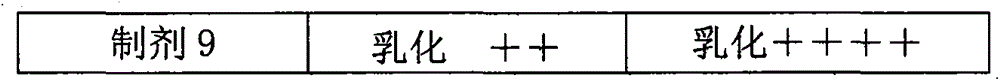

Preparation method for tulathromycin emulsifable injection

ActiveCN104095815AReduced dosing volumeImprove stabilityAntibacterial agentsOrganic active ingredientsBody fluidBiocompatibility

Poloxamer 188 and an oily medium are composed to prepare an oily injection containing tulathromycin; defined amount of hydrogenated castor oil and soya lecithin can be further added in the prepared oily injection containing tulathromycin; the oily injection containing tulathromycin is mainly characterized in that the prepared oily injection is emulsified when encountering water or liquid to generate a mixed system with emulsion droplets and oil; the quick releasing effect and long-acting effect are achieved and the prepared oily injection is defined as an emulsifable oily injection. The prepared oily injection has the characteristics that the drug loading capacity is high, the stability is good and the biocompatibility is excellent and the like.

Owner:王玉万 +1

Novel method for preparing tulathromycin

ActiveCN102260306BReduce manufacturing costReduce stepsSugar derivativesSugar derivatives preparationEpoxyAzithromycin

The invention discloses a novel method for preparing tulathromycin and relates to a semi-synthetic macrolide antibiotic. The method comprises the following steps: simultaneously protecting 2'-hydroxyl and 6a-amino of desmethyl azithromycin with acetyl, then carrying out oxidation and epoxidation on 4''-hydroxy, then removing the protecting groups under alkaline alcohol solution conditions, and carrying out nucleophilic addition on 4''-epoxy group with n-propylamine to obtain the target compound tulathromycin. Compared with the prior art, the method for preparing tulathromycin has the advantages of simple process, mild conditions, high yield and the like, and is beneficial to industrial production.

Owner:SHANDONG LUKANG SHELILE PHARMA

Tulathromycin oxalate

ActiveCN107400152AHigh yieldAvoid ultra-low temperature reactionsSugar derivativesSugar derivatives preparationTulathromycinInorganic chemistry

The invention discloses salt of tulathromycin, particularly oxalate, a preparation method of tulathromycin oxalate and application of tulathromycin oxalate to preparation of tulathromycin.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

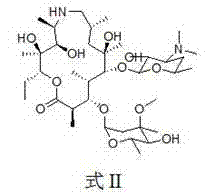

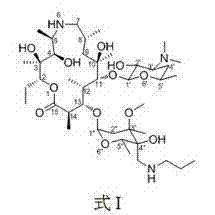

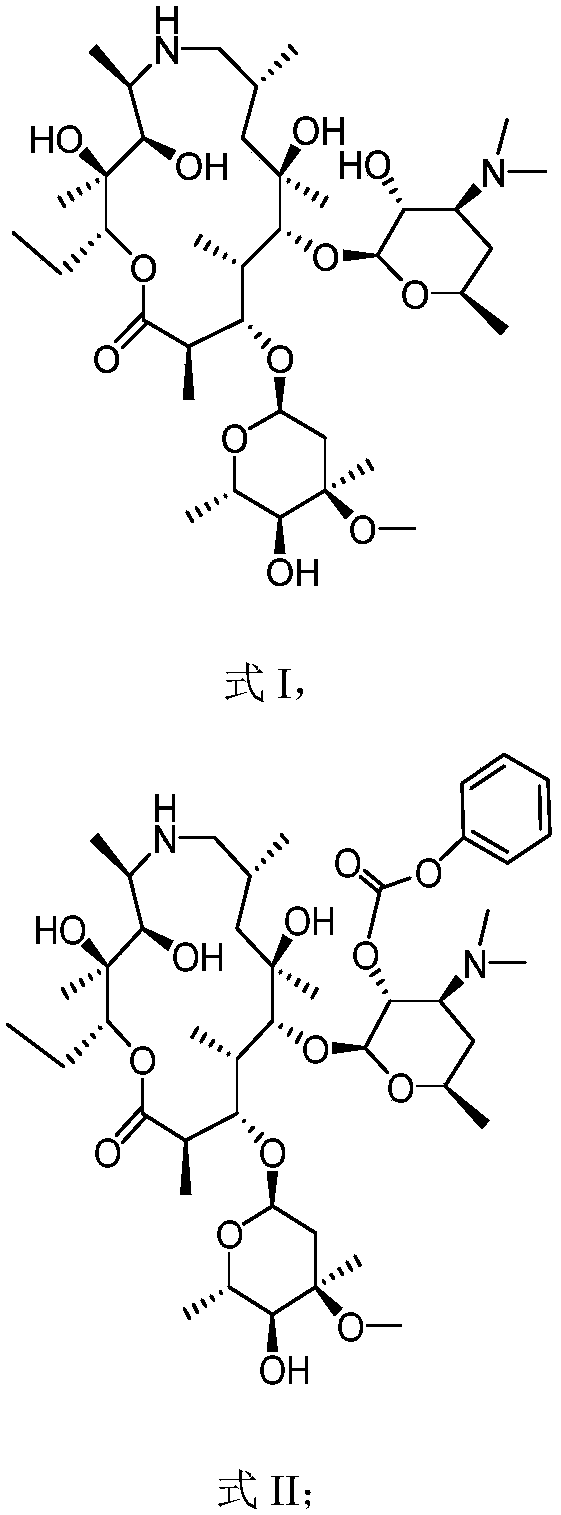

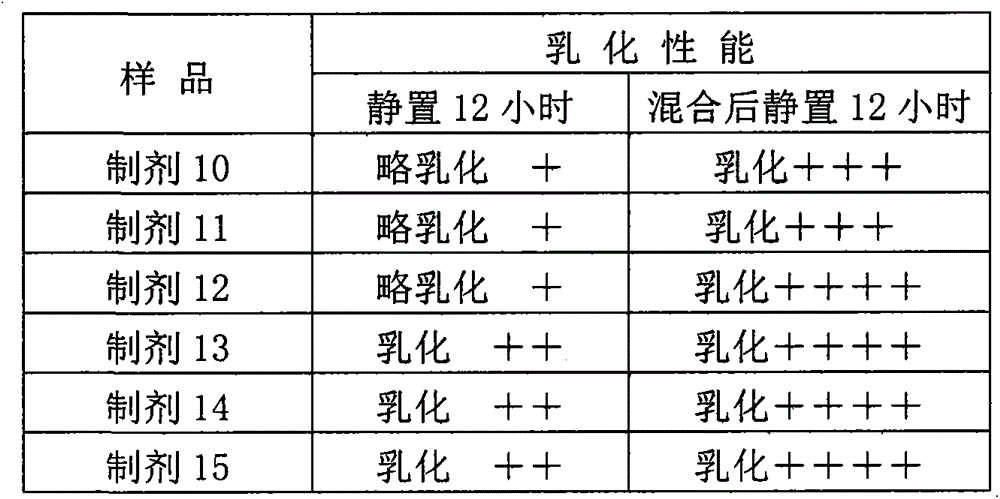

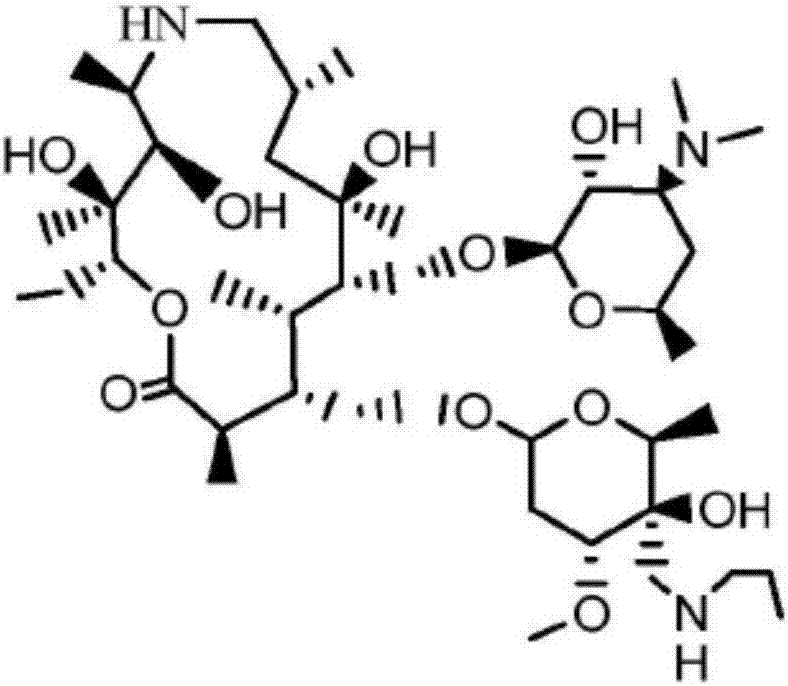

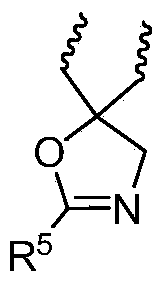

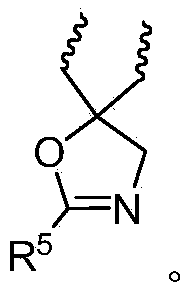

Macrolide compound and preparation method and application thereof

InactiveCN104248642AAntibacterial agentsOrganic active ingredientsMacrolide resistanceStereoisomerism

The invention provides an anti-infection pharmaceutical composition. The pharmaceutical composition contains an effective amount of a compound shown as a formula (I). The composition and pharmaceutically acceptable salt, ester, amide, stereoisomer or racemic mixture thereof can effectively prevent and treat various bacterial and protozoal infections, and have effect better than that of tulathromycin. The invention also relates to a preparation method and application of the compound.

Owner:PU LIKE BIO ENG

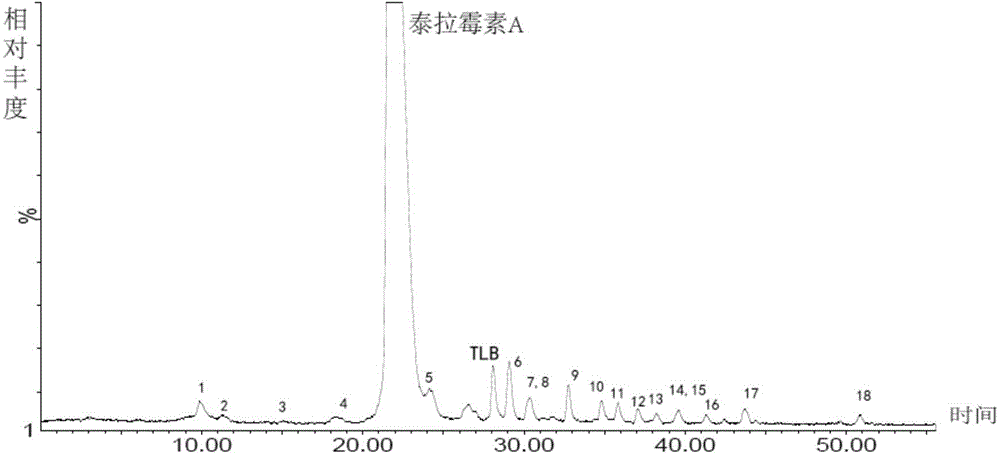

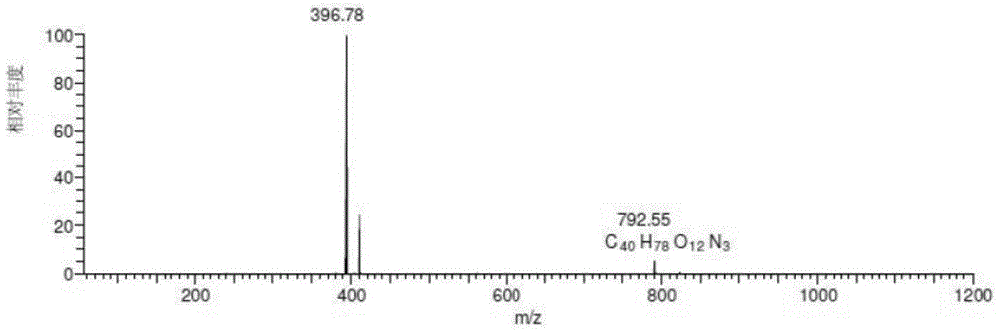

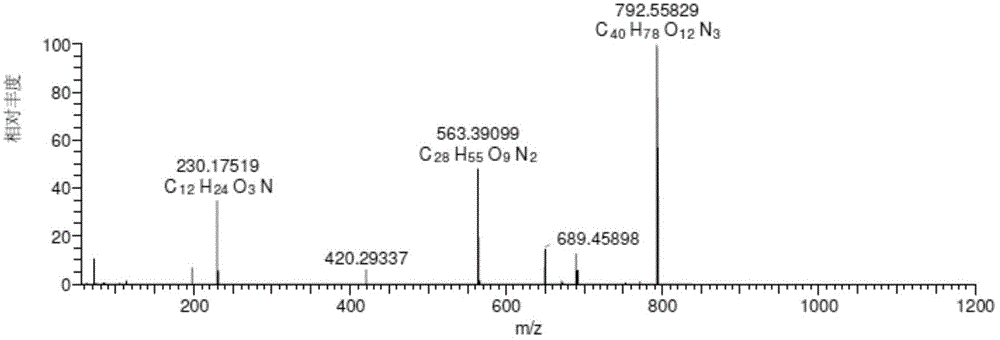

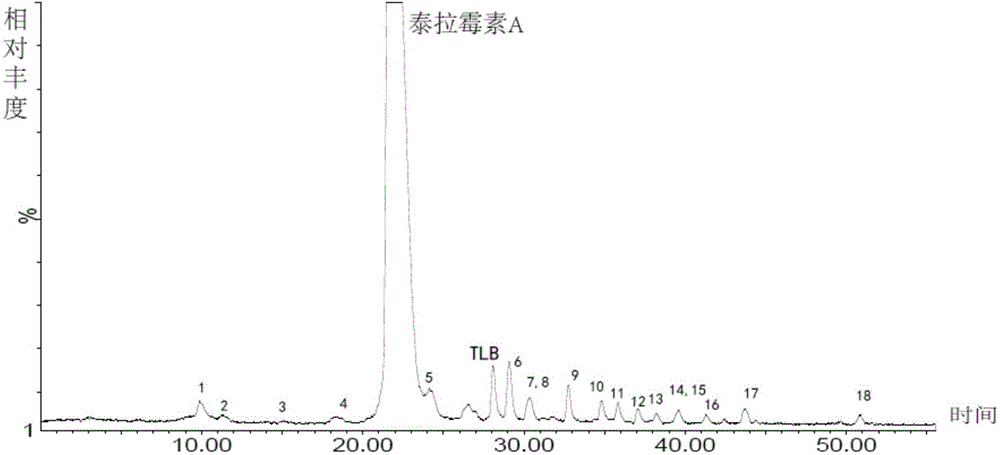

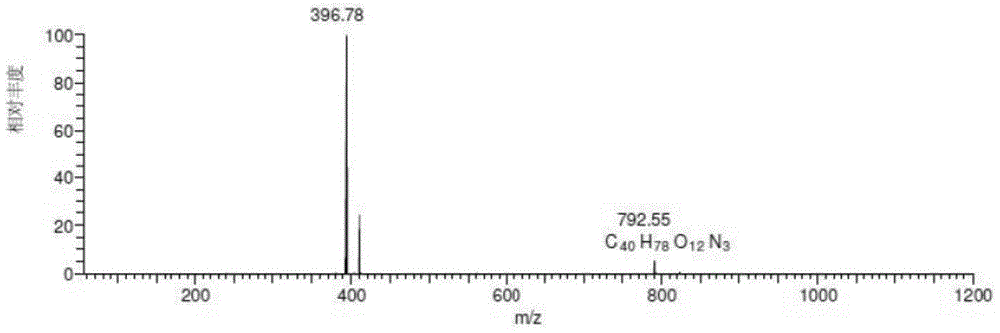

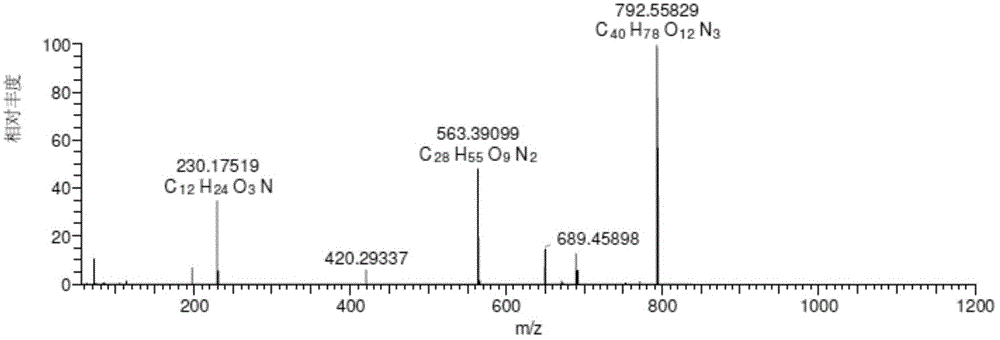

Tulathromycin related substance, and enriching preparing method, separation method and application thereof

ActiveCN106146576AControl drug qualityEfficient separationSugar derivativesComponent separationQuality controlMass spectrometry

The invention discloses a tulathromycin related substance, and an enriching preparing method, a separation method and an application thereof. The invention provides the separation method of the tulathromycin related substance, wherein the separation method comprises the following steps: adopting high performance liquid chromatography, eluting a to-be-tested material in a chromatographic column, and thus obtaining the product. The invention also provides the tulathromycin related substance 1 or a salt thereof. The separation method can effectively separate impurities produced in synthesis and degradation processes of tulathromycin, trace impurities can be detected further by mass spectrometric detection with high sensitivity, and the structure is identified and confirmed, so that the drug quality of tulathromycin is controlled, and a good foundation is laid for study of tulathromycin unknown impurities; the tulathromycin related substance is a necessity for quality control of tulathromycin.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

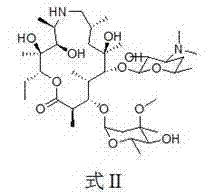

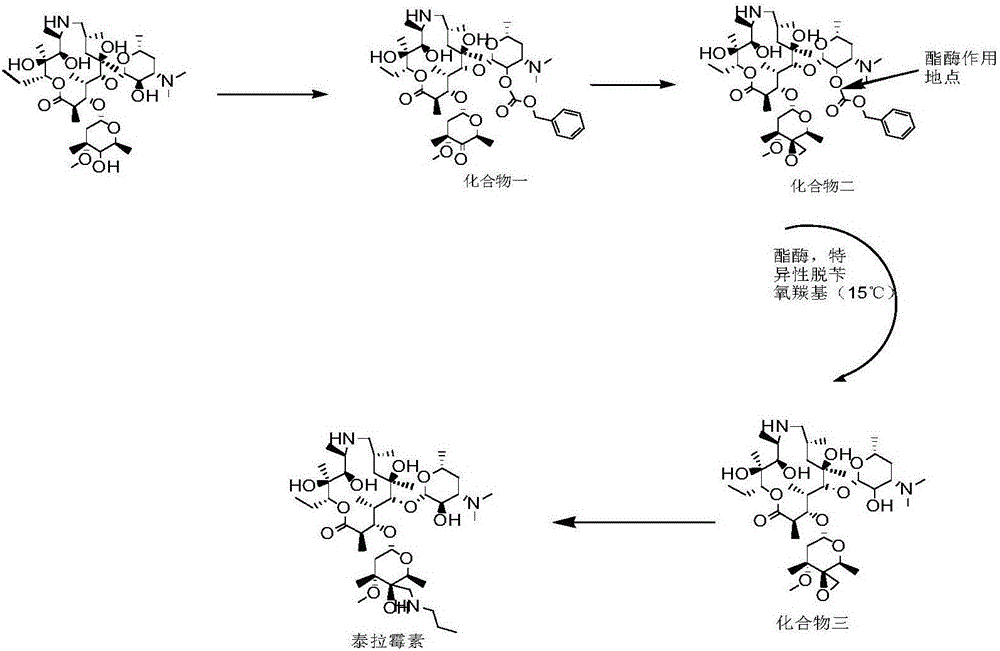

Technology for enzymatic synthesis of tulathromycin

The invention relates to a method for synthesizing a veterinary medicine, and in particular, relates to a method for enzymatic synthesis of tulathromycin. A compound II and a immobilized esterase are added to water, after each-time reaction, a mother liquor and the immobilized lipase only require to be filtered and separated, and the immobilized esterase only requires to be washed with deionized water and can be reused; the synthesis process has the advantages of simple technology, convenience in operation, short reaction time, high production efficiency, low cost and less pollution.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

Tulathromycin related substance, enriching and preparation method and application thereof

ActiveCN106153740AControl drug qualityEfficient separationComponent separationQuality controlDrug product

The invention discloses a telamycin related substance, its enrichment preparation method and application. The present invention provides a telamycin related substance 3 or a salt thereof. The present invention also provides a method for enriching telamycin-related substances 3, which includes the following steps: using high-performance liquid chromatography to elute the analyte in a chromatographic column, and collecting telamycin-related substances 3 is enough. The telamycin-related substance of the present invention is a necessity for quality control of the telamycin; the enrichment preparation method of the present invention can effectively separate the telamycin-related substance 3, thereby controlling the drug quality of the telamycin, for The study of unknown impurities of telamycin has laid a good foundation.

Owner:SHANGHAI INST OF PHARMA IND +1

Salt for tulathromycin intermediate

ActiveCN107501364AHigh yieldAvoid ultra-low temperature reactionsSugar derivativesCarboxylic acid salt preparationOxalateTulathromycin

The invention discloses a salt for preparing a tulathromycin intermediate, and particularly relates to oxalate and a preparation method thereof as well as application of the oxalate in a method for preparing tulathromycin.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com