Preparation method of rhodamine bispyrazole acetate organic laser material

A bispyrazole acetate and bispyrazole acetic acid technology, which is applied in the field of rhodamine bispyrazole acetate organic laser materials, can solve the problems that plague the development of organic lasers and the difficulty of realizing organic lasers, and achieve excellent thermal stability The effect of high performance, low preparation cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

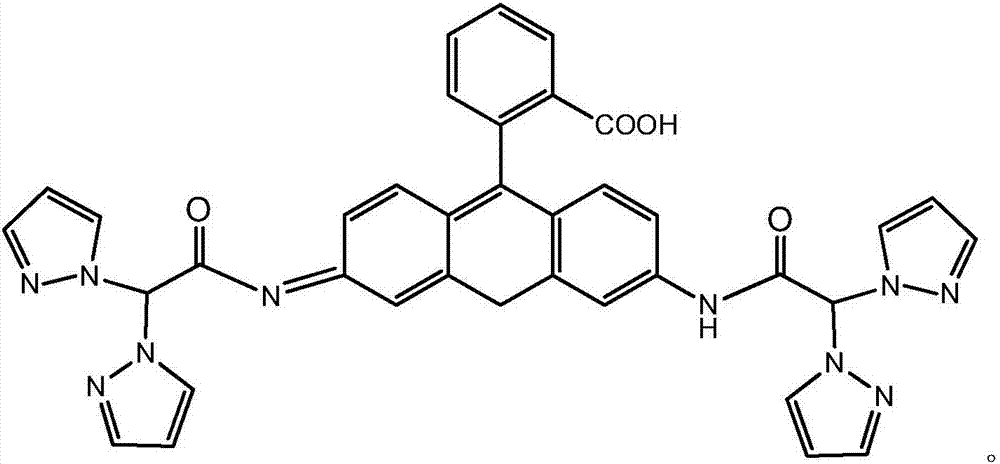

Image

Examples

Embodiment 1

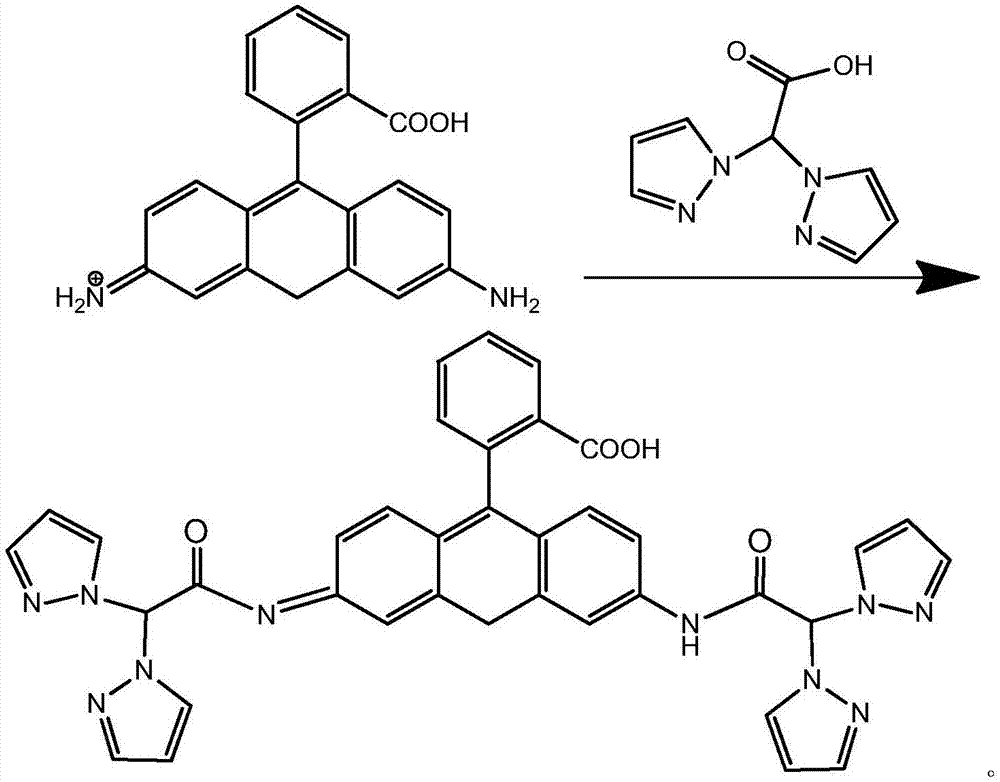

[0018] The preparation method of rhodamine bispyrazole acetate organic laser material comprises the following steps: in the presence of triethylamine, rhodamine 110 and bis(1-pyrazole)acetic acid are reacted at room temperature for 3-5 hours to obtain bispyrazole Acetic acid coumarin derivative; wherein, the molar ratio of bis(1-pyrazole), rhodamine 110, and triethylamine is 1.1:1:3; the yield is 85.6%;

[0019] The reaction formula is:

[0020]

Embodiment 2

[0022] The preparation method of rhodamine bispyrazole acetate organic laser material comprises the following steps: in the presence of triethylamine, rhodamine 110 and bis(1-pyrazole) acetic acid are reacted at room temperature for 5 hours to obtain bispyrazole acetic acid aroma Soybein derivatives; wherein, the molar ratio of bis(1-pyrazole), rhodamine 110, and triethylamine is 1:1:2; the yield is 84.2%.

Embodiment 3

[0024] The preparation method of rhodamine bispyrazole acetate organic laser material comprises the following steps: in the presence of triethylamine, rhodamine 110 and bis(1-pyrazole) acetic acid are reacted at room temperature for 3 hours to obtain bispyrazole acetic acid fragrance Soybein derivatives; wherein, the molar ratio of bis(1-pyrazole), rhodamine 110, and triethylamine is 1.2:1:4; the yield is 83.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Gain coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com