Method for preparing graphene nanopore array through chemical vapor deposition by using porous anodic alumina (PAA) as template

A graphene nanopore and alumina template technology, applied in the field of low-dimensional materials and new materials, can solve the problems of uneven distribution of holes, low yield, high hardware equipment requirements, etc., and achieve the effect of excellent controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

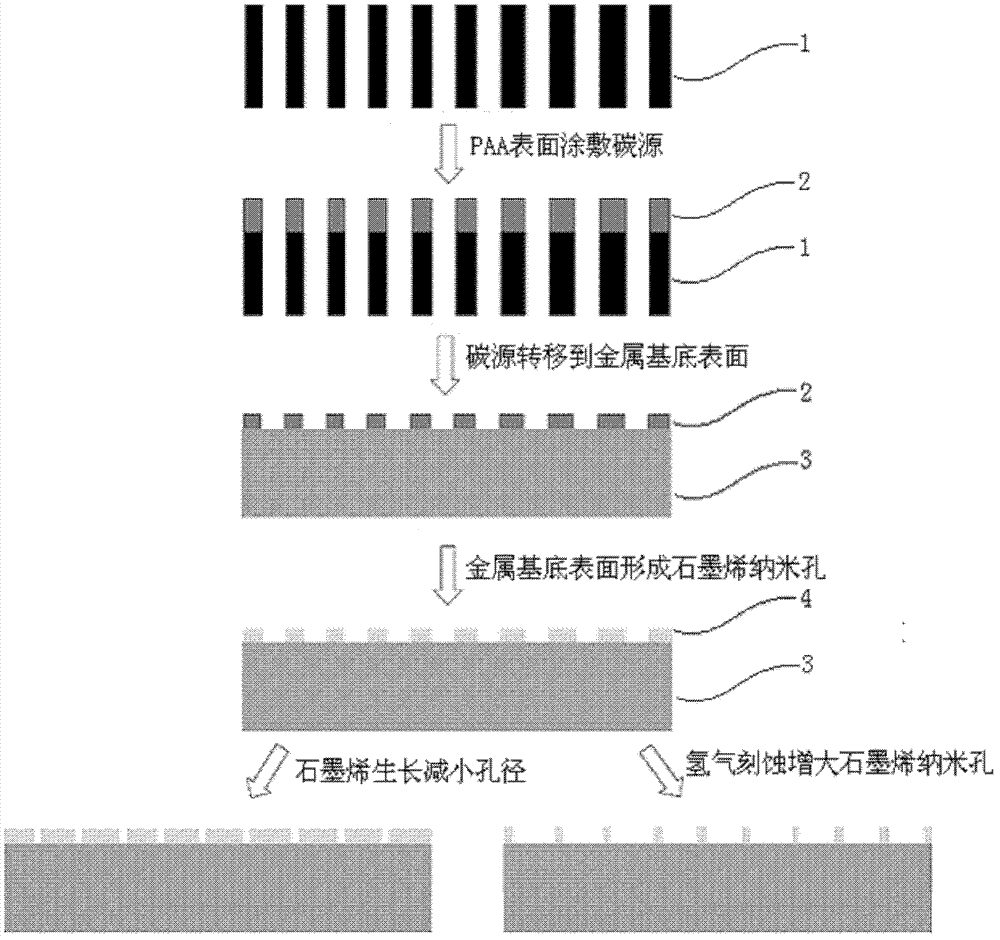

[0037] figure 1 It is a schematic flow chart of the preparation method of the present invention, in which 1 is a schematic cross-sectional view of a PAA template, 2 is a carbon source coated on the surface of PAA, 3 is a metal substrate, and 4 is a graphene nanopore formed on the surface of a metal substrate. Such as figure 1 Shown, the present invention adopts the porous anodic aluminum oxide (PAA) obtained by said method as template, has prepared graphene nanohole array, specifically comprises the steps:

[0038] 1) Coating the carbon source solution on the surface of PAA;

[0039] 2) Press the PAA template coated with the carbon source obtained in step 1) on the surface of the metal substrate, peel off the PAA template, keep the carbon source on the surface of the metal substrate and keep the carbon source on the surface of the PAA template Consistent patterns, forming a patterned distribution of carbon sources on the metal surface;

[0040] 3) annealing the metal substr...

Embodiment 1

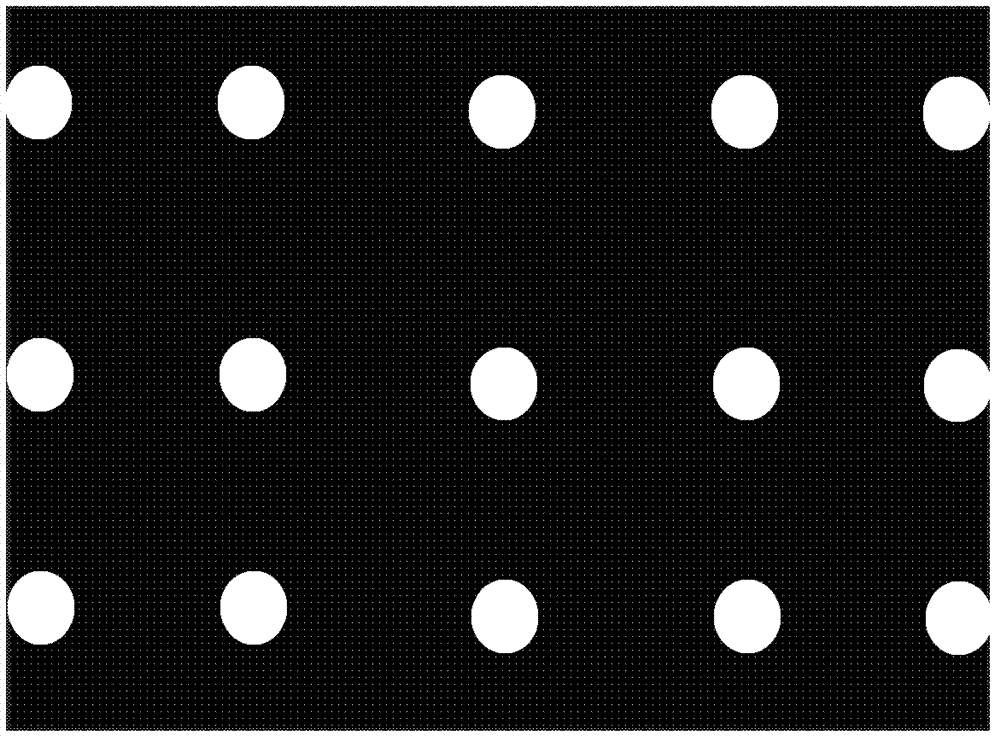

[0045] Embodiment 1: the preparation of the graphene nanohole array that aperture is 10-90nm

[0046] The first step: prepare PAA template and copper substrate treatment, and apply carbon source on the surface of PAA. The aluminum sheet with a purity of 99.999% is mechanically and electrochemically polished to make the surface smooth; 0.3M oxalic acid aqueous solution is used as the electrolyte, the temperature of the electrolyte is 0°C, the electrolysis voltage is 40V, and the electrolysis is performed for 1 hour; Immerse the oxide layer in a phosphochromic acid solution at 60°C for 1 hour to remove the oxide layer; use the same process to perform secondary electrolysis to obtain a PAA template with a pore diameter of about 40nm and a pore wall of about 60nm. The atomic force microscope and field emission scanning electron microscope test results Such as Figure 4 and 5 shown. The copper sheet with a purity of 99.9% is mechanically and electrochemically polished to make th...

Embodiment 2

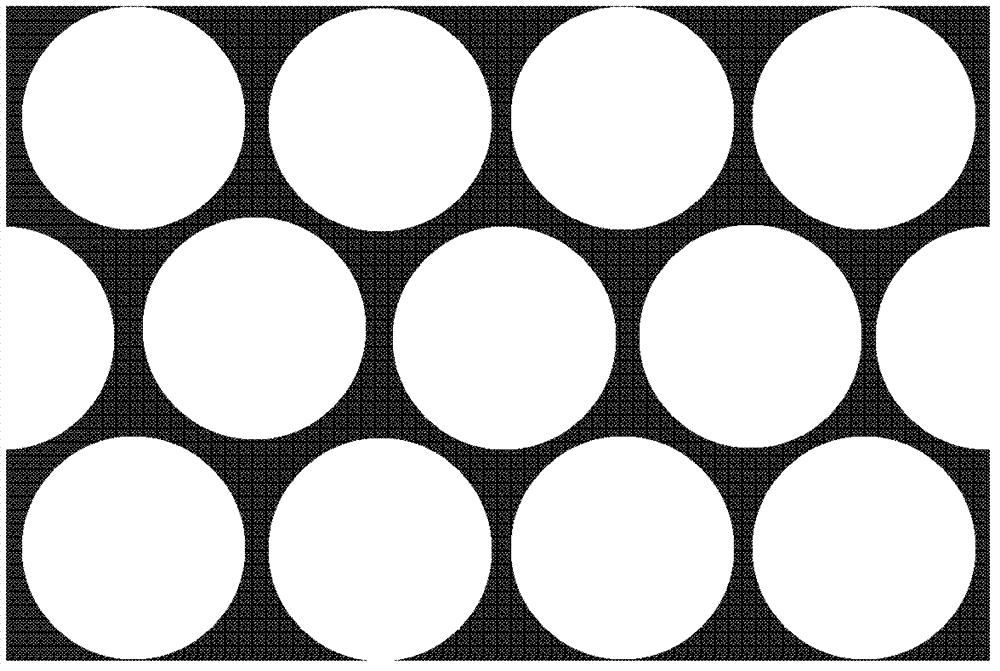

[0051] Embodiment 2: a graphene nanohole array with an aperture of 1-10 nanometers

[0052] The first step: similar to the first step in Example 1, the difference is that the voltage of the primary and secondary electrolysis of aluminum is 10V, the PAA pore diameter obtained is 10nm, and the pore wall is 10nm, and the difference is that the carbon source used is naphthalene.

[0053] The second step: the same as the second step in Example 1.

[0054] The third step: the substrate with the carbon source pattern is heated up to 1000° C. in a mixed gas of hydrogen and argon for heat treatment. Wherein: the hydrogen flow rate is 10 sccm, the argon flow rate is 200 sccm, and the temperature is kept for 30 minutes. The surface atomic force microscope photos and the field emission scanning electron microscope photos show that the graphene nanohole array is obtained, and the pore size is about 10nm.

[0055] Step 4: On the basis of the sample obtained in the third step, 2 sccm of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com