Preparation method of panchromatic structural color or color variation pattern array

A color pattern and structural color technology, applied in the field of full-color structural color or color-variable color pattern array, can solve the problems of large-area preparation and practical application of unfavorable samples, high cost, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

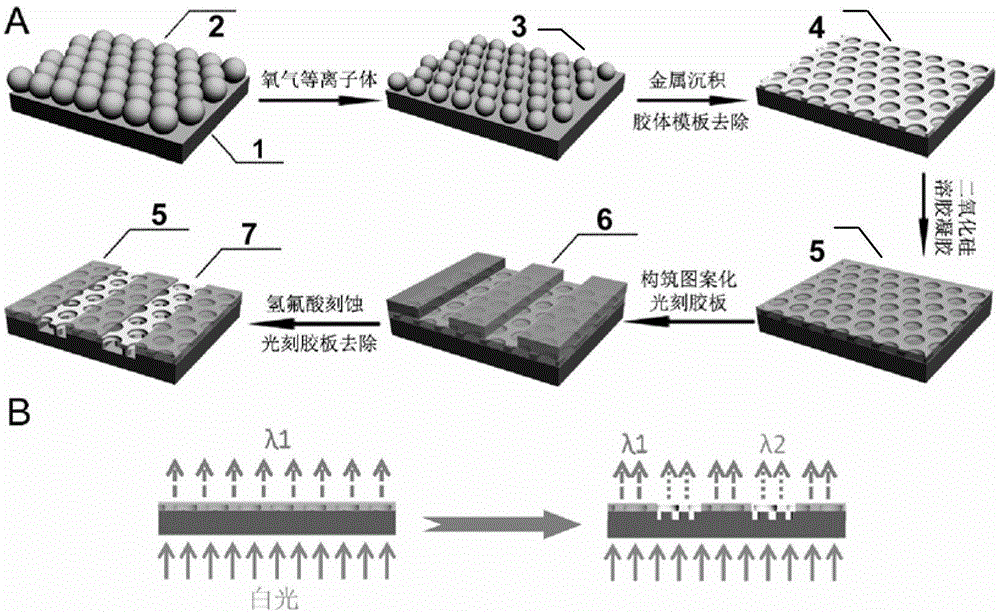

Method used

Image

Examples

Embodiment 1

[0046] 1. Cleaning and surface hydrophilization of glass slide substrates:

[0047]The glass slides were ultrasonically cleaned with acetone for 10 minutes, anhydrous ethanol for 10 minutes, dried, and acidic treatment solution (a mixed solution of concentrated sulfuric acid with a mass fraction of 98% and hydrogen peroxide with a mass fraction of 30%, the volume ratio of the two solutions is 7:3) boiled for 20 minutes, rinsed with deionized water, and then dried under nitrogen or air atmosphere to obtain a glass slide substrate with surface cleaning and hydrophilization treatment;

[0048] 2. The preparation method of polystyrene microspheres:

[0049] Under nitrogen protection, with 100mL of absolute ethanol and 40mL of deionized water as the dispersion medium, 10.5mL of styrene, 0.2222g of potassium persulfate, and 0.2445g of sodium dodecylsulfonate were added to the And in the reactor of the reflux condenser, the mechanical stirring speed is at 300r / min. Dispersion polym...

Embodiment 2

[0057] 1. See Example 1 for the preparation method of polystyrene microspheres and the preparation method of polystyrene monolayer microspheres.

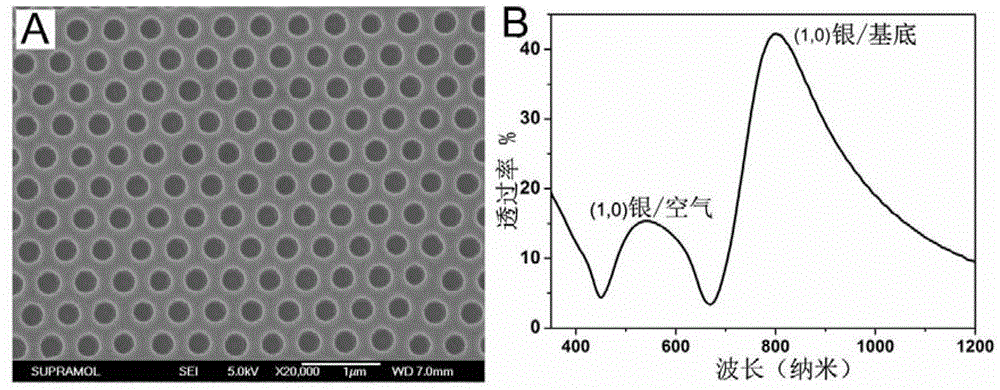

[0058] 2. See Example 1 for the preparation method of the silver nanohole array sample whose apparent color is green.

[0059] 3. The preparation of the silica layer-coated silver nanohole array sample whose apparent color is blue:

[0060] The silica layer on the surface of the silver nanopore array was prepared by spin-coating silica sol on the surface of the sample, and then gelling in an oven at 135° C. for 10 minutes. The preparation method of silica sol is briefly described as follows. First, 5mLSi(OC 2 h 5 ) 4 Dissolve in 5mL ethanol to prepare solution A; add 81μL concentrated hydrochloric acid to 1.935mL water to prepare solution B. Then, under stirring at 70°C, solution A was slowly added dropwise into solution B within 20 minutes and reacted for 2 hours. Finally, the system was cooled to room temperature and the rea...

Embodiment 3

[0064] 1. See Example 1 for the preparation method of polystyrene microspheres and the preparation method of polystyrene monolayer microspheres.

[0065] 2. See Example 1 for the preparation method of the silver nanohole array sample whose apparent color is green.

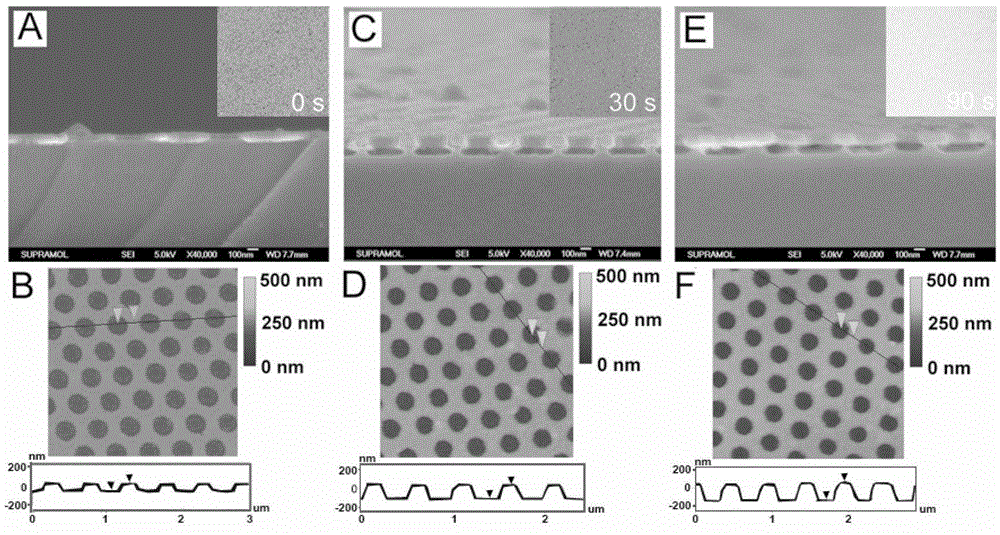

[0066] 3. Preparation of silver nanopore surface patterned photoresist plate:

[0067] We spin-coated at a rate of 4000rpm / min for 1min to spread the positive photoresist (BP212-37, Beijing Microelectronics Co., Ltd.) The photolithography technology was used to expose and develop with 0.5% sodium hydroxide aqueous solution as the developing solution. After development, the photoresist in the exposed areas is washed away, exposing the substrate, while the unexposed areas are still covered by photoresist. The pattern of the photoresist plate is determined by the commercial photoresist plate. By changing the pattern of the photoresist plate, we can obtain a photoresist plate with any pattern with a feature size abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com