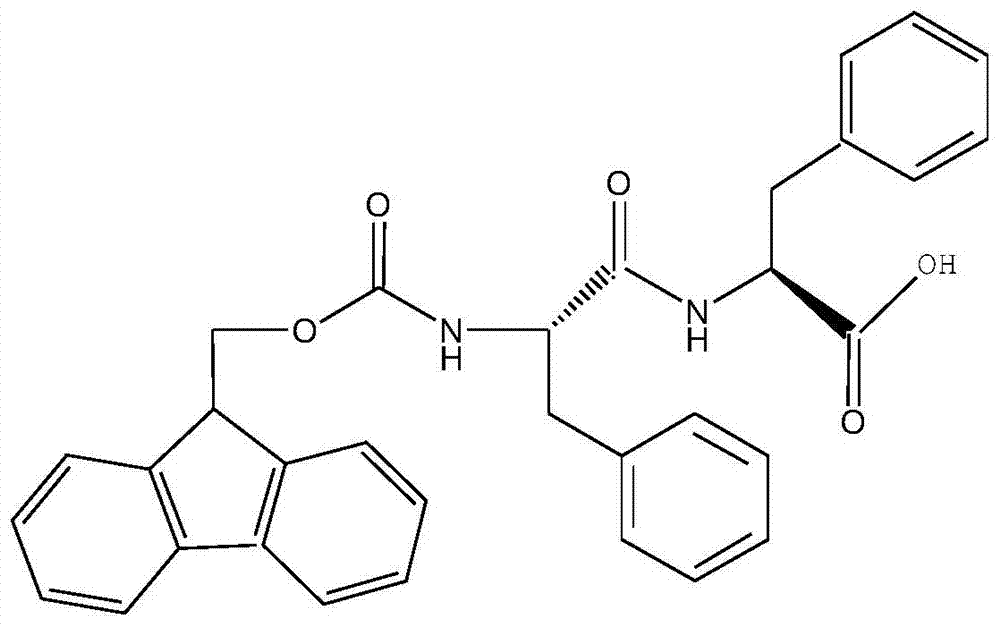

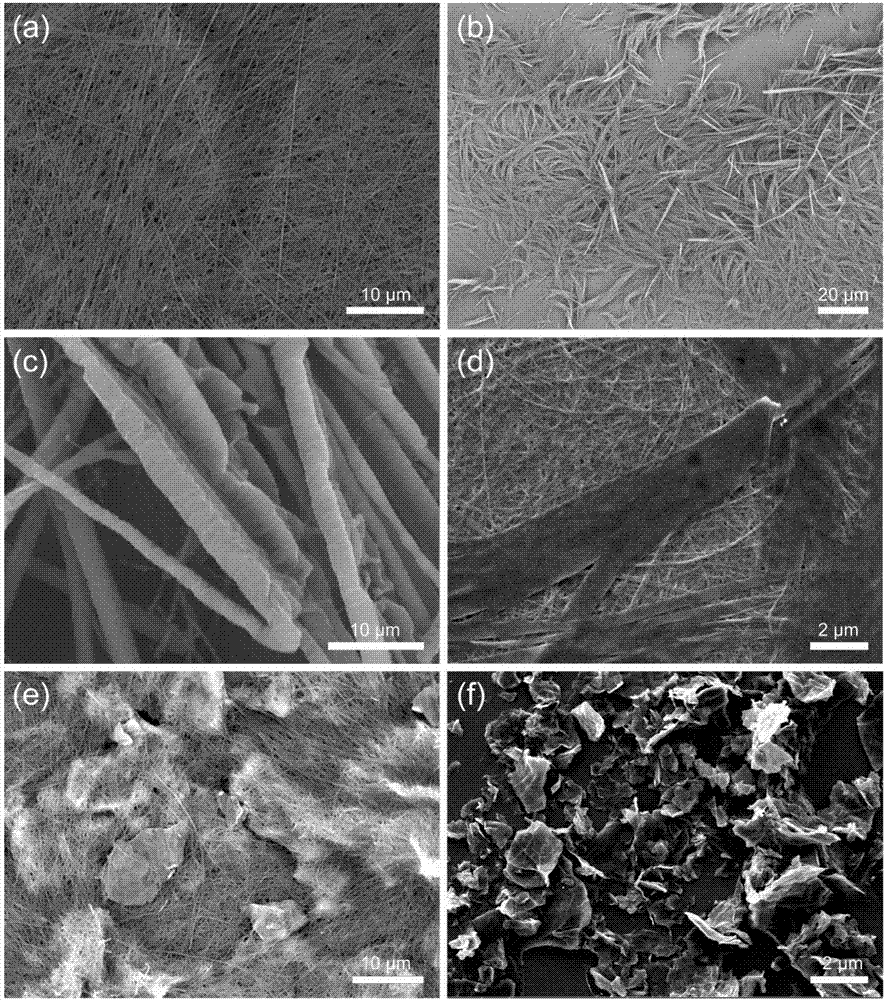

Preparation method of dipeptide derivative Fmoc-FF self-assembly fiber by graphene oxide regulation

A technology of peptide derivatives and self-assembly, applied to the chemical characteristics of fibers, textiles and papermaking, etc., to achieve obvious effects, simple methods, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Prepare GO by Hummers method, the method is as follows:

[0055] A. Preoxidation

[0056] ①Weigh 12~18g K 2 S 2 o 8 and 12-18g P 2 o 5 Add to the 500ml round bottom flask successively,

[0057] ②Put the round-bottomed flask in an 80°C water bath,

[0058] ③ Measure 70-80ml of sulfuric acid into the round bottom flask,

[0059] ④Stir for 20-30min until the solution becomes clear,

[0060] ⑤ Add 20g graphene to the round bottom flask under protective measures,

[0061] ⑥Stir for 4.5 hours at 80°C,

[0062] ⑦Take out the round bottom flask, let it cool for a few minutes, then add the black mixture into a 2L Erlenmeyer flask,

[0063] ⑧ Add deionized water, make the volume constant to 2L, and collect the solid product with a vacuum filtration device,

[0064] ⑨The solid product is continuously rinsed with deionized water, and the pH value is checked until the pH value reaches about 5.

[0065] ⑩Let the product dry overnight.

[0066] B. Oxidation

[0067] ...

Embodiment 2

[0086] (1) prepare GO with Hummers method, with embodiment 1;

[0087] (2) Dissolve GO into deionized water with the help of an ultrasonic instrument, the ultrasonic time is 15min, the power frequency is 40KHz, and the large flakes of suspended GO are removed by centrifugation (3000rpm, 10min) to obtain a GO solution with a concentration of 0.03%;

[0088] (3) Prepare Fmoc-FF solution. Weigh Fmoc-FF and add it to HFIP, dissolve to obtain Fmoc-FF solution, wherein the ratio of Fmoc-FF to HFIP is 100mg: 1ml;

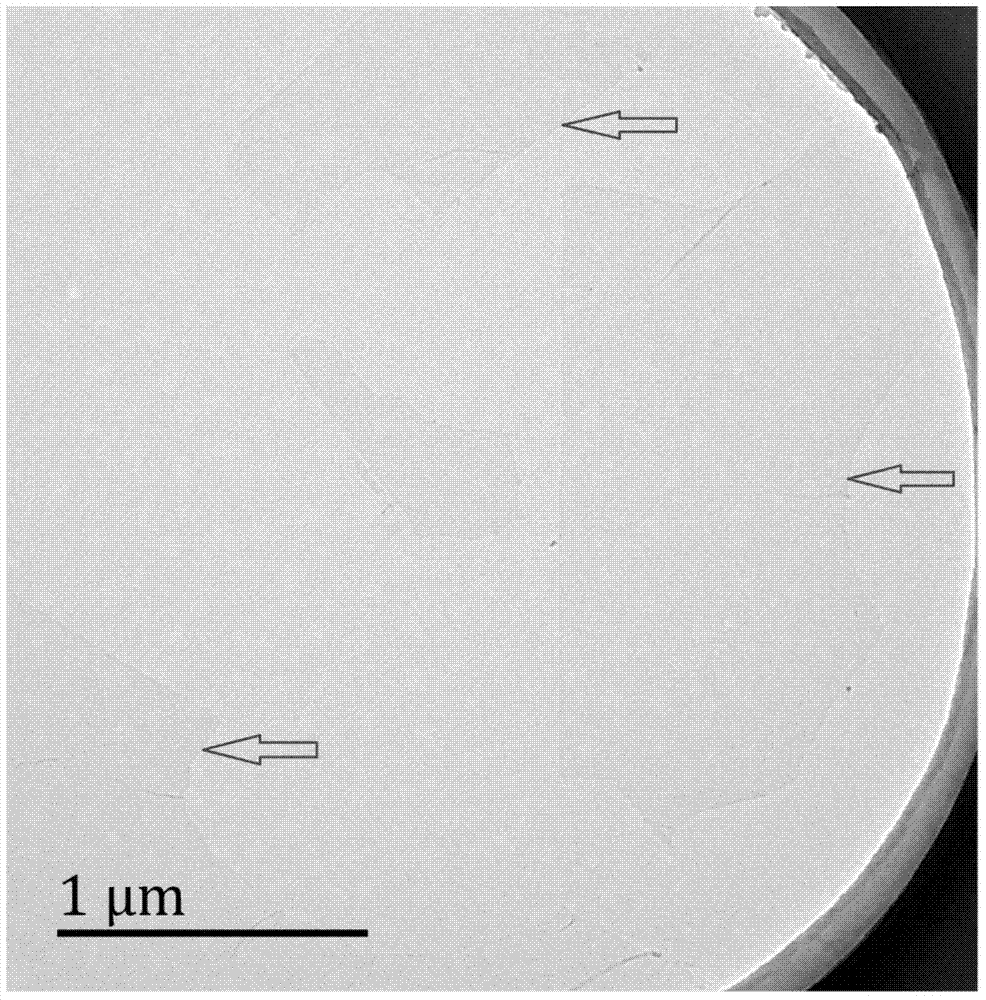

[0089] (4) Quickly add the GO solution to the Fmoc-FF solution dropwise, oscillate (the vortex oscillator shakes, the shaking time is 60s, and the rotation speed is 2000rpm / min), and mix well to obtain the Fmoc-FF / GO mixed system, wherein the Fmoc- The volume ratio of FF solution and GO is 30μl; 1ml;

[0090] (5) Immediately before the gelation of the mixed system, the above solution was drawn and dropped onto a clean silica glass plate, and then the samples were placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com