Method for manufacturing micro-nano graph on sapphire substrate

A sapphire substrate, micro-nano technology, applied in the field of semiconductors, can solve the problems of expensive equipment, high cost, difficulty in achieving nanometer precision, etc., and achieve the effect of improving crystal quality and optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

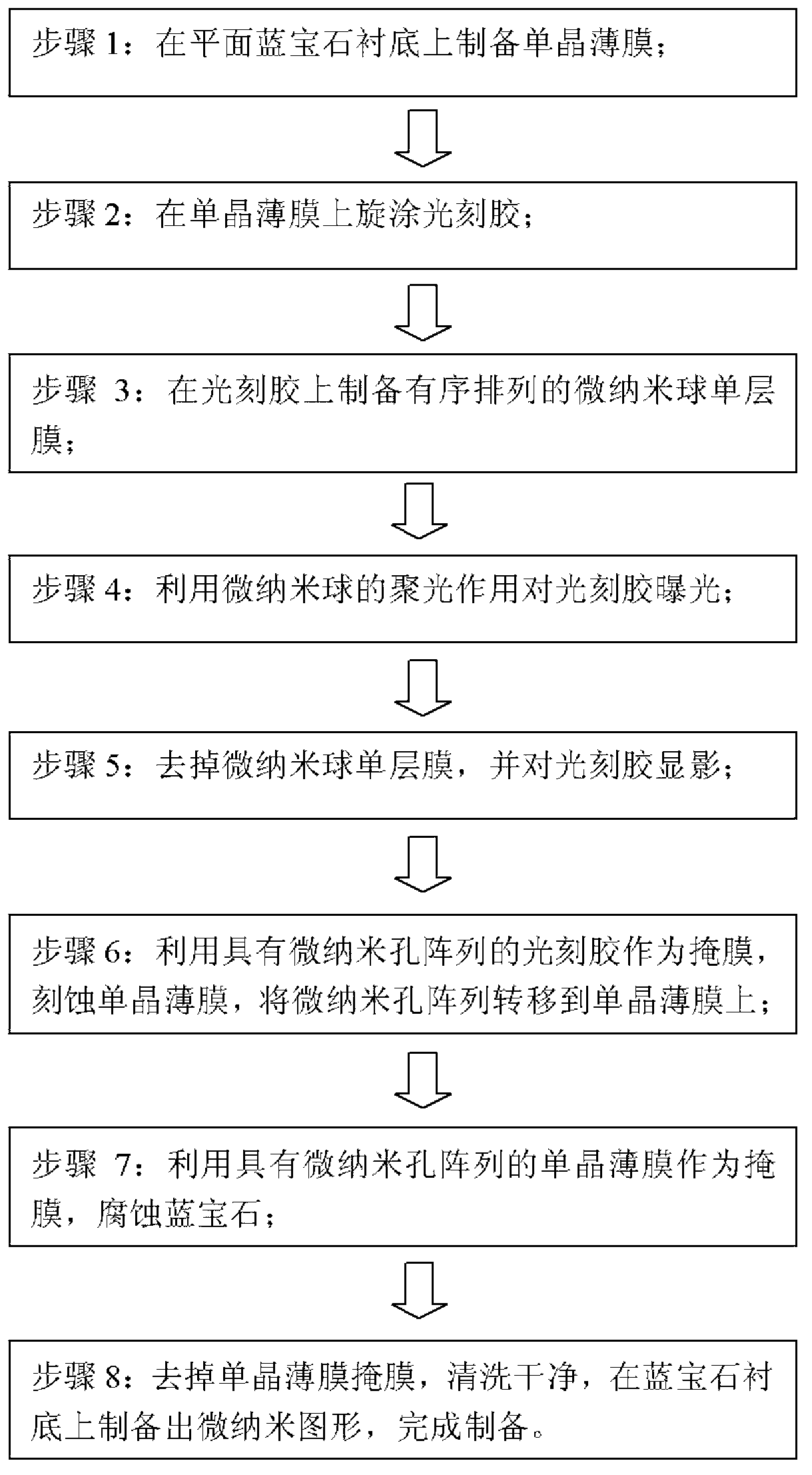

[0018] Please refer to figure 1 , and see in conjunction with Figure 2 to Figure 6 Shown, the present invention provides a kind of method preparing micro-nano pattern on sapphire substrate, comprises the following steps:

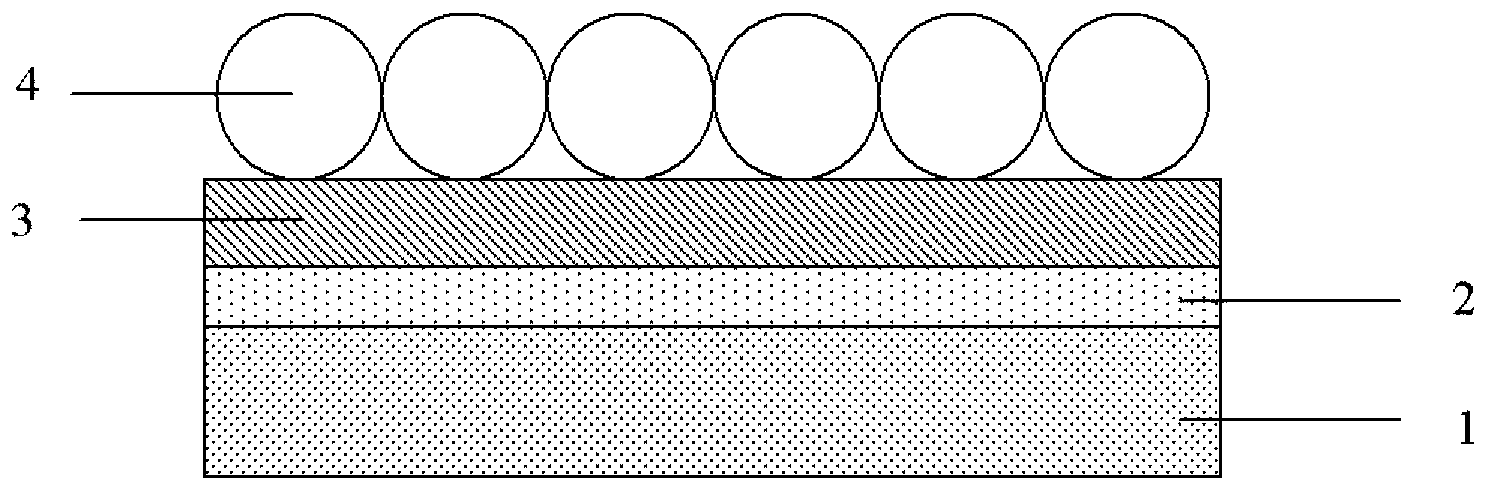

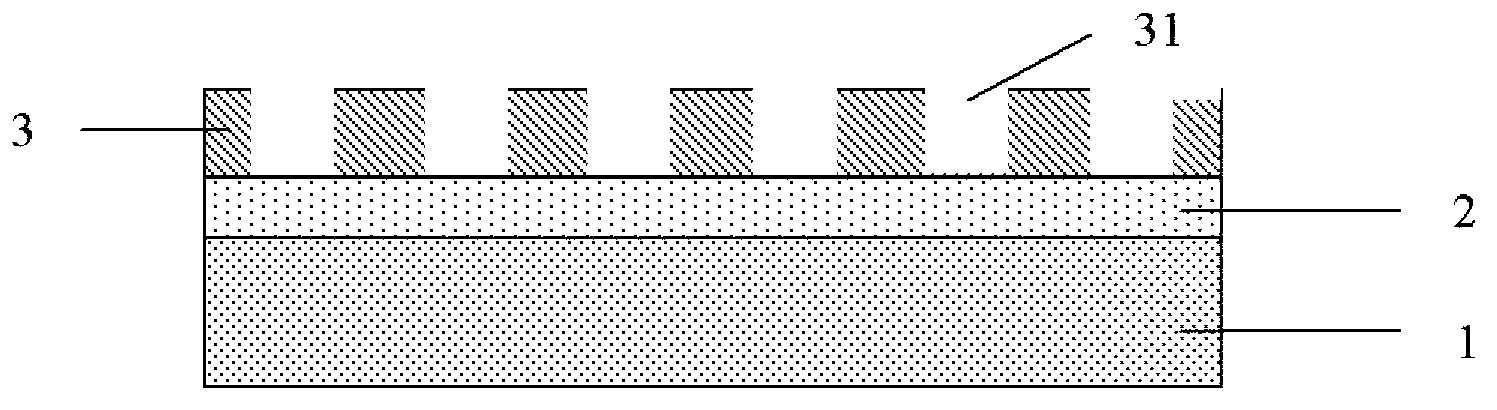

[0019] Step 1: prepare a single crystal film 2 on a sapphire substrate 1, the sapphire substrate 1 is a planar sapphire substrate, the size is not limited, the shape is not limited; the material of the single crystal film 2 is silicon dioxide, nitrogen One, two or more of silicon carbide or silicon carbide, can be one layer, two layers or multiple layers, its thickness is 10nm-10000nm, its preferred thickness is 100nm-500nm, its preparation method can adopt plasma enhanced Preparation methods such as vapor deposition, electron beam evaporation or magnetron sputtering.

[0020] Step 2: Spin-coat a layer of photoresist 3 on the single crystal film 2, the photoresist 3 is a positive photoresist with a thickness of 100nm-5000nm, preferably 200nm-2000nm; the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com