Vertical streamline tunnel wheel gas turbine

A gas turbine and streamline technology, which is applied in gas turbine devices, liquid fuel engines, mechanical equipment, etc., can solve the problems of reducing structural strength and power consumption, and achieve the effects of improving stability, reducing losses, and reducing axial loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

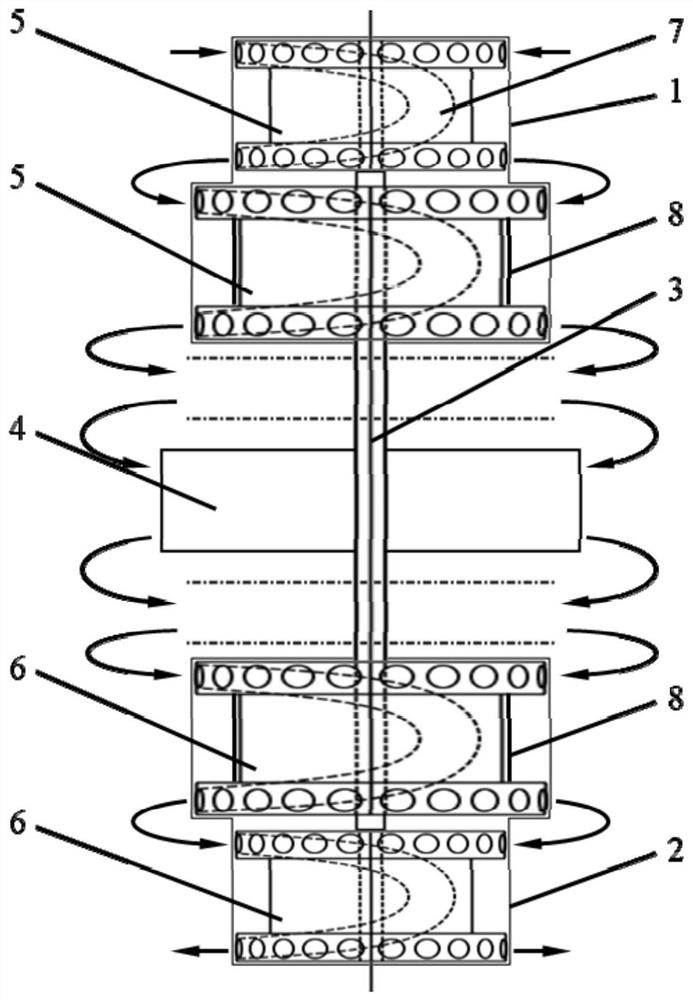

[0023] Such as figure 1 As shown, a vertical streamlined tunnel gas turbine includes a compressor 1, a gas turbine 2, a shaft 3, and a combustion chamber 4; the compressor 1 and the gas turbine 2 are respectively installed at the upper and lower ends of the shaft 3 to form a gas turbine The rotor; the combustion chamber 4 is located between the compressor 1 and the gas turbine 2; the shaft 3 is placed vertically to form a vertical structure.

[0024] In order to make the compressor 1 have a reasonable layout, further, the compressor 1 can be arranged in a single stage or in multiple stages, and in case of multiple stages, multiple streamline tunnel compressor wheels 5 are installed on the shaft 3 in sequence.

[0025] In order to make the gas turbine 2 have a reasonable arrangement, further, the gas turbine 2 can be arranged in a single stage or multi-stage, and in case of multi-stage, multiple streamline tunnel turbines 6 are installed on the shaft 3 in sequence.

[0026] In...

Embodiment 2

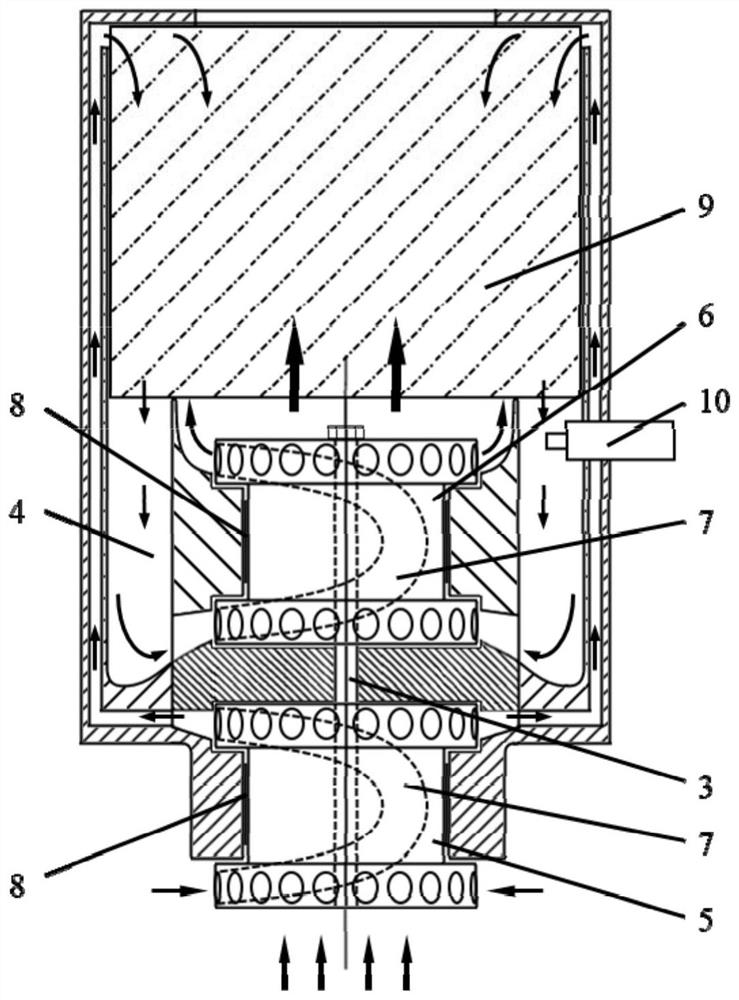

[0030] Such as figure 2 As shown, with respect to Embodiment 1, in this embodiment, the vertical streamline tunnel gas turbine also includes a regenerator 9 installed downstream of the outlet of the streamline tunnel turbine 6, and the regenerator 9 utilizes the heat of exhaust gas after the turbine to The incoming air is heated, and the preheated air is combusted in the combustor 4 with the fuel ejected from the fuel nozzle 10, thereby improving the efficiency of the gas turbine; the regenerator 9 has various arrangements, including but not limited to as figure 2 structure shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com