Rhythm-type high-frequency hydraulic pulse oscillation resistance-reducing actuator

A technology of hydraulic pulse and speed booster, which is applied to vibration drilling, drilling equipment, drilling equipment and methods, etc., can solve problems such as bit damage, excessive compression of drilling tools, and increased risk of drilling tool overturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

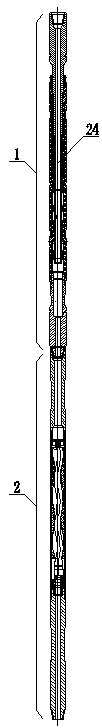

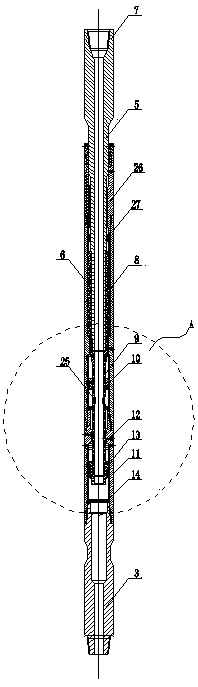

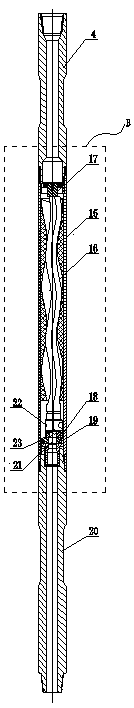

[0016] The joint rate type high-frequency hydraulic pulse oscillation drag reduction and speed-up device of the present invention is composed of a combination of a peristaltic sub-joint 1 and a power sub-joint 2, both of which are hollow tubular, and the peristaltic sub-joint 1 passes through The lower joint 3 below it is threadedly connected with the upper joint 4 above the power nipple 2, and a pulse channel 24 is formed in the middle. The creeping short joint 1 is composed of a splined mandrel 5 plugged into a sleeve 6 through a coupling sleeve 26. The coupling sleeve 26 is seated on the top of the sleeve 6, and a wear-resistant ring 27 is provided at the joint. On the top of the spline mandrel 5, there is an externally expanded drilling tool upper joint 7, which is connected to the upper drilling tool; a disc spring 8 is installed in the annular gap between the lower part of the spline mandrel 5 and the sleeve 6, and the disc spring 8 The piston rebounds when the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com