Reciprocating low pressure high frequency hydraulic pulse vibrator

A hydraulic pulse and reciprocating technology, applied in vibration drilling and other directions, can solve problems such as high working pressure loss and vibration force, difficult tool face control, and large rotor torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

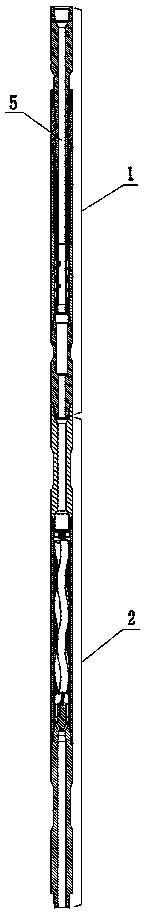

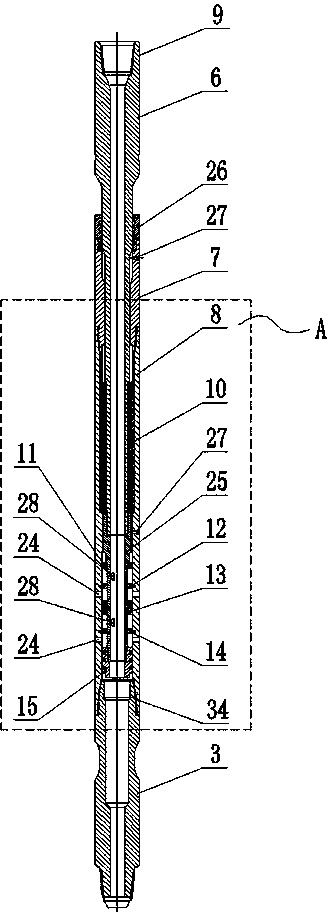

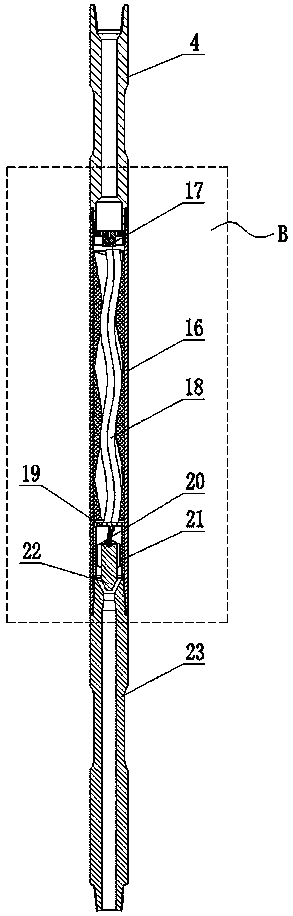

[0016] Such as Figure 1-5 As shown, the reciprocating low-pressure high-frequency hydraulic impulse vibrator of the present invention is composed of a combination of a vibrating sub-section 1 and a power sub-section 2. The vibrating sub-section 1 and the power sub-section 2 are both hollow and tubular, and the vibrating sub-section 1 passes The lower joint 3 underneath is threadedly connected with the upper joint 4 above the power nipple 2, so that a pulse channel 5 is formed between the vibrating nipple 1 and the power nipple 2. Specifically, the spline core shaft 6, the spline outer cylinder 7, the piston inner cylinder 25, the piston outer cylinder 8, the lower joint 3, the upper joint 4, the stator sleeve 16 and the bottom joint 23 are all hollow tubulars, and the pulse channel 5 It is composed of a spline mandrel 6, a piston inner cylinder 25, a lower joint 3, an upper joint 4, a stator sleeve 16, a flushing channel 21 and a bottom joint 23 connected in sequence.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com