Universal-type flow meter based on wing principle

A general-purpose flowmeter technology, applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detected by measuring pressure difference, etc., can solve problems such as large limitations of process pipelines, easy blockage of pressure guiding pipes, and inconvenient maintenance , to achieve the effect of good sensing repeatability, high reliability and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

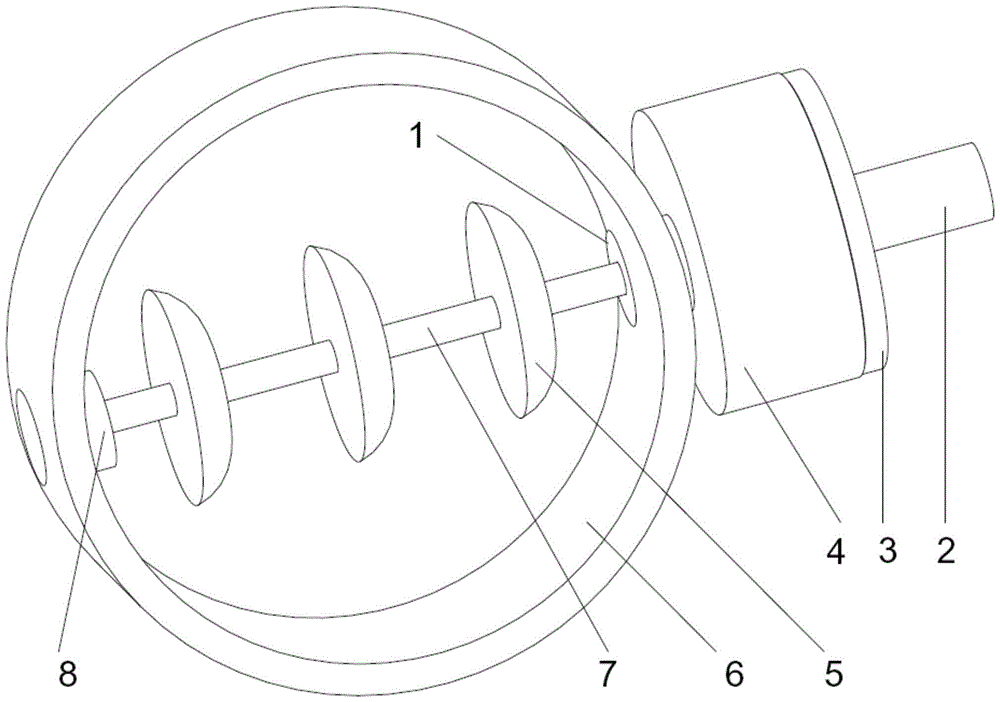

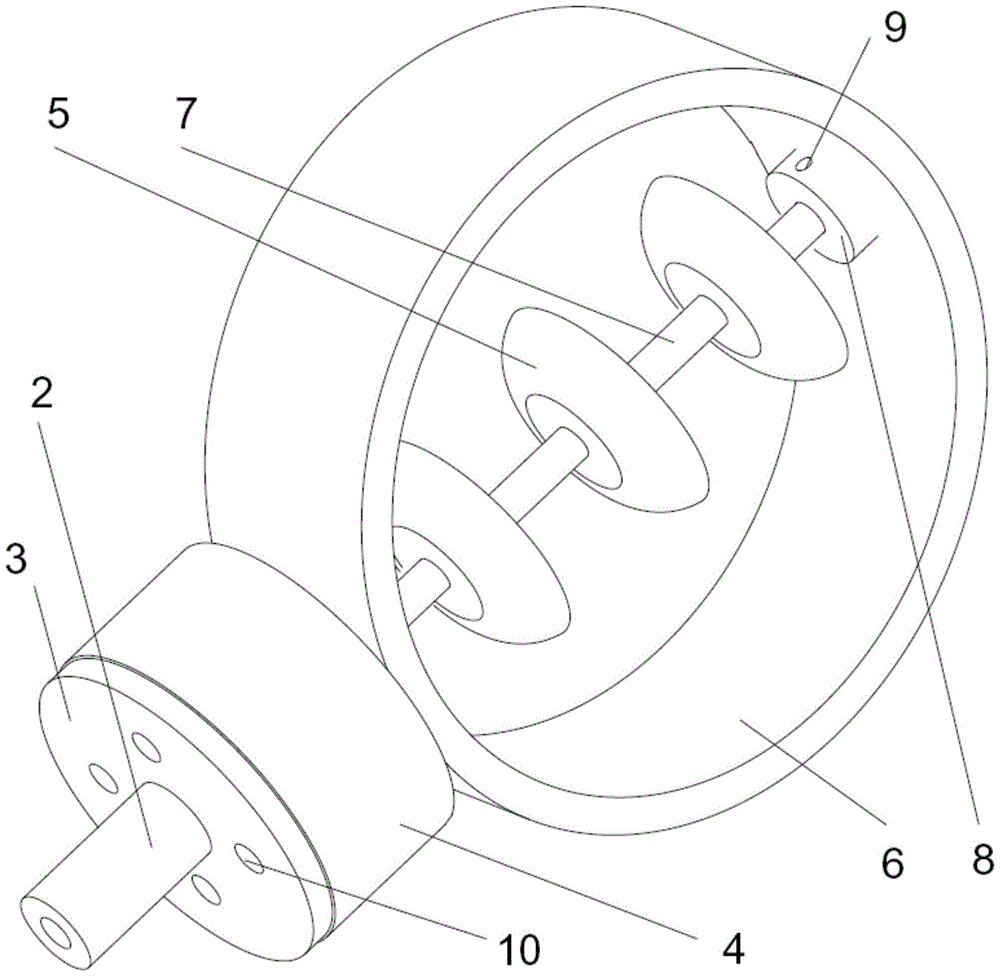

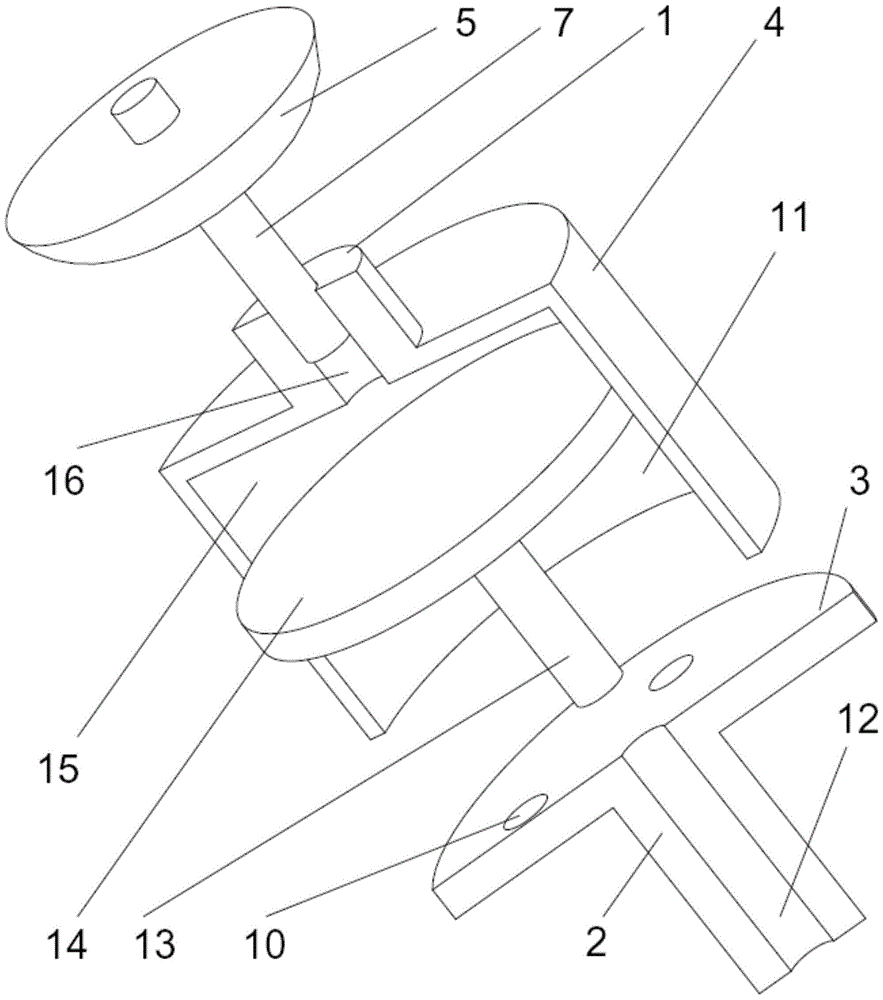

[0032] Embodiments of the present invention, such as Figure 1 to Figure 6As shown, the general-purpose flowmeter based on the wing principle includes a wing-type sensor set in the process pipeline 6, and a detection signal transmission device adapted to connect with the wing-type sensor; the wing The sensor includes a plurality of disk wings 5 distributed at intervals and coaxially connected in series through a shared wing shaft 7 arranged horizontally. The axis of the shared wing shaft 7 is also perpendicular to the central axis of the process pipeline 6. The cross section of the wing 5 is in the shape of D; the inner wall surface of the tube on the side of the straight surface of the D is provided with a shaft sleeve 8, and the tube wall on the side of the curved surface of the D is provided with a supporting cylinder sleeve 1, and the supporting cylinder The outer end of the sleeve 1 protrudes from the wall of the process pipeline 6; the two ends of the common wing shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com