Anti-torque automatic balancing device, drilling string and method for screw drilling tools

一种自动平衡、螺杆钻具的技术,应用在钻孔设备和方法、钻管、钻具等方向,能够解决使用及维护成本昂贵、钻井成本降低等问题,达到钻进和维护成本低、提高机械钻速、轴向摩阻降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention will be further described below with reference to the accompanying drawings.

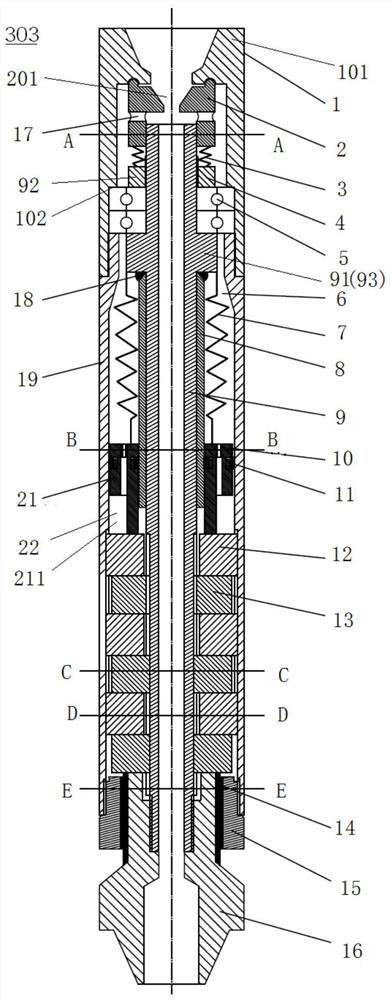

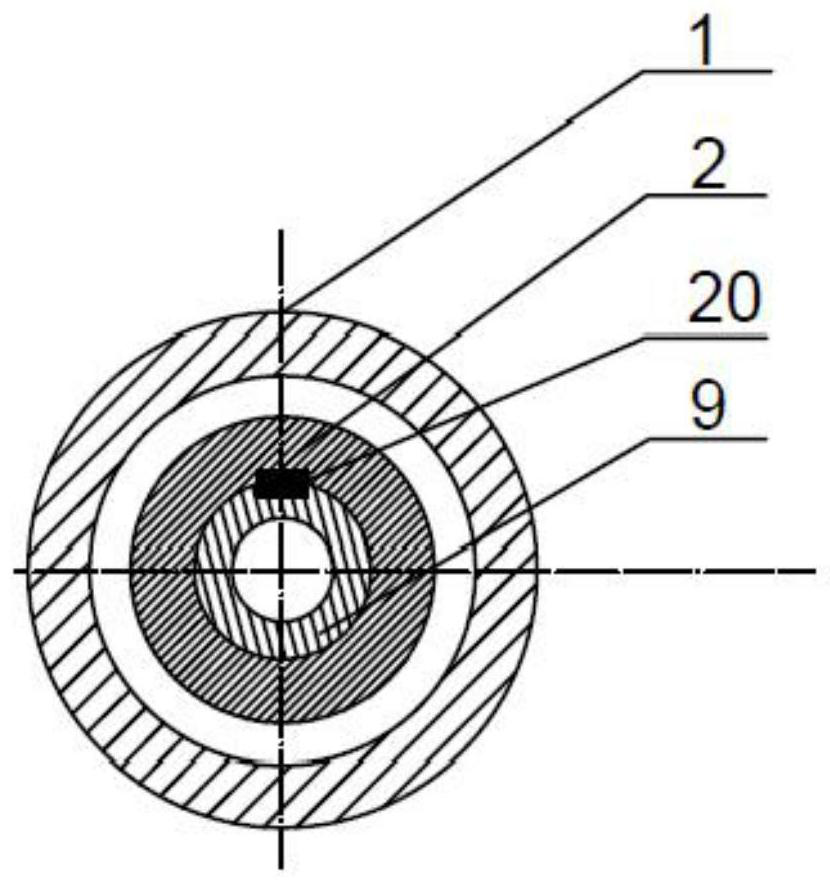

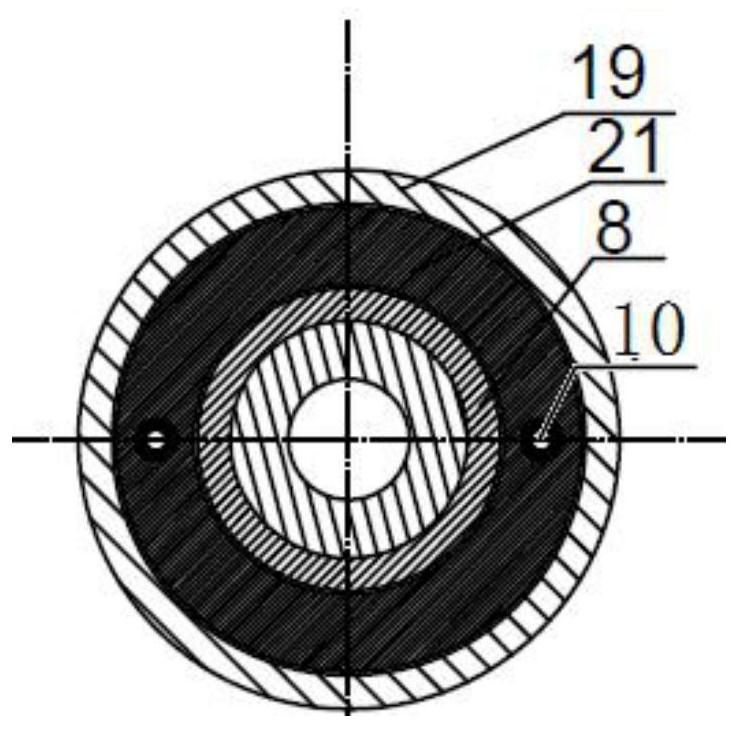

[0047] figure 1 The anti-torque automatic balancing device 303 for the screw drill 305 is shown in accordance with one embodiment of the present invention. like figure 1 As shown, the anti-torque automatic balancing device 303 includes an upper connector 1, a lower joint 16, a core 9, and an automatic balancing component. Among them, if Figure 7, The upper joint is a cylindrical shape for the upper drill string with the drilling tube 302 is connected. 9 cartridge itself is also cylindrical, is provided for in the interior of the joint 1, and the lumen of the cartridge 1 lumen joint 9 communicates. In operation, the cartridge lumen downstream of the drill screw 9 305 communicates to the rear interior of the joint 1 by pumping drilling fluid, the drilling fluid flows through the lumen of the cartridge screw drill 305 9 305 such that the screw hole drilling. And the lower joint 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com