Low-friction reciprocating motion seal component

A technology of reciprocating motion and seals, applied in the direction of engine seals, engine components, springs, etc., can solve problems such as poor seal drainage of lubricants, loss of lubricating oil, dry grinding of seals, etc., and achieve flexibility and follow-up , Axial friction reduction, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

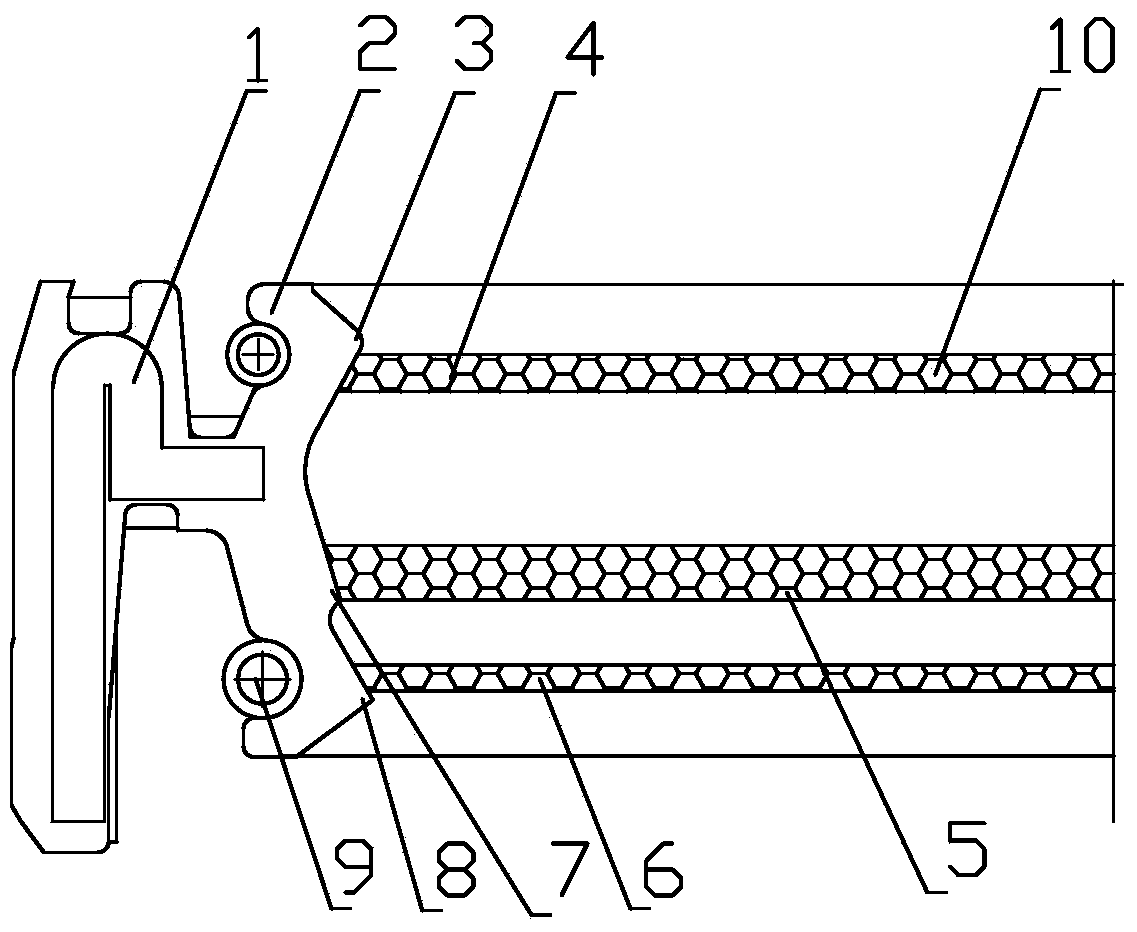

[0048] Such as figure 1 with Image 6 As shown, a low-friction reciprocating seal includes an annular support frame 1 and an annular elastic sealing body 22. The annular elastic sealing body 2 includes at least one sealing lip, and the annular sealing surface formed by the sealing lip is provided with The concave-convex surface ring belt is provided with a plurality of protrusions 10 .

[0049] The shape of the protrusion 10 is polygonal truncated.

[0050] The height of the protrusion 10 is 0.02mm.

[0051] The rest of the structures are as described above and will not be repeated here.

Embodiment 2

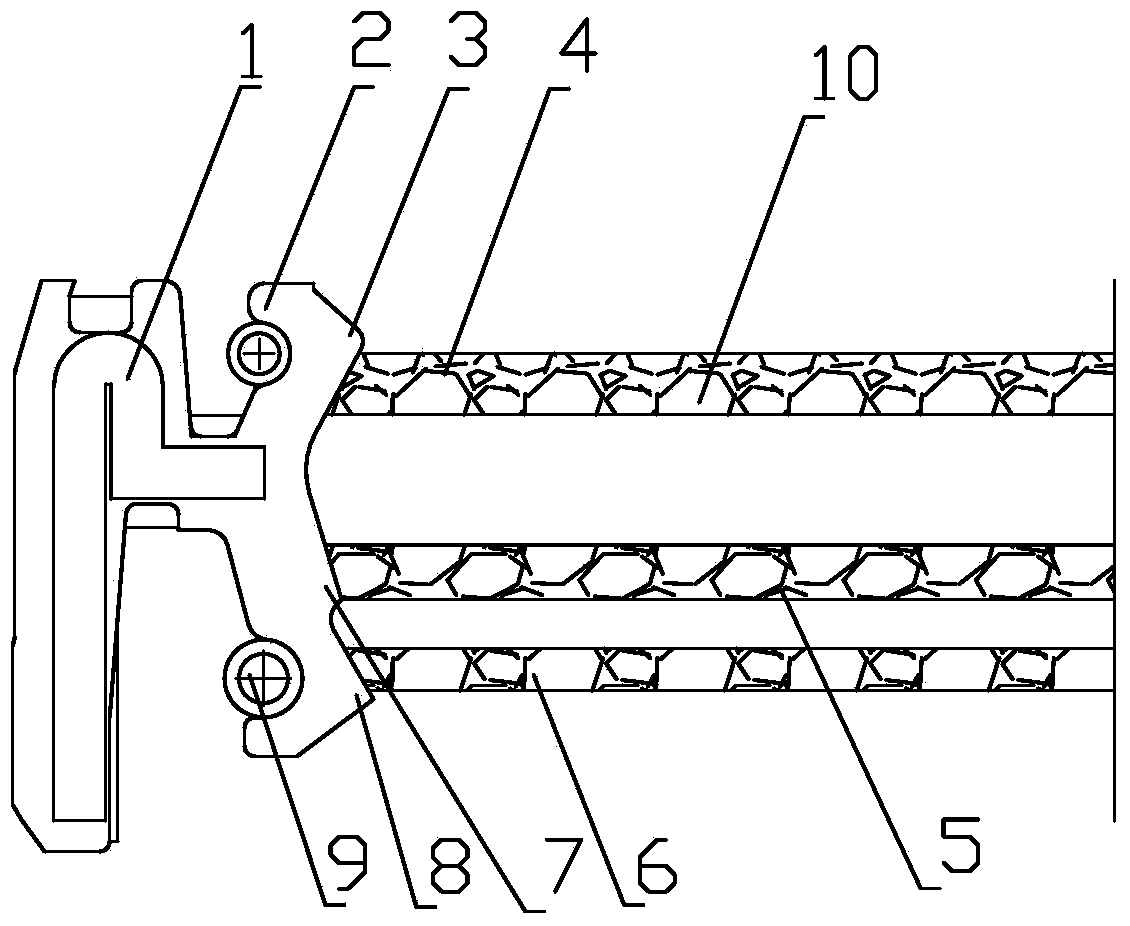

[0053] Such as figure 2 with Figure 7 As shown, a low-friction reciprocating seal includes an annular support frame 1 and an annular elastic sealing body 2. The annular elastic sealing body 2 includes at least one sealing lip, and the annular sealing surface formed by the sealing lip is provided with The concave-convex surface ring belt is provided with a plurality of protrusions 10 .

[0054] The protrusions 10 are randomly distributed on the annular sealing surface.

[0055] The height of the protrusion 10 is 0.10mm.

[0056] The rest of the structures are as described above and will not be repeated here.

Embodiment 3

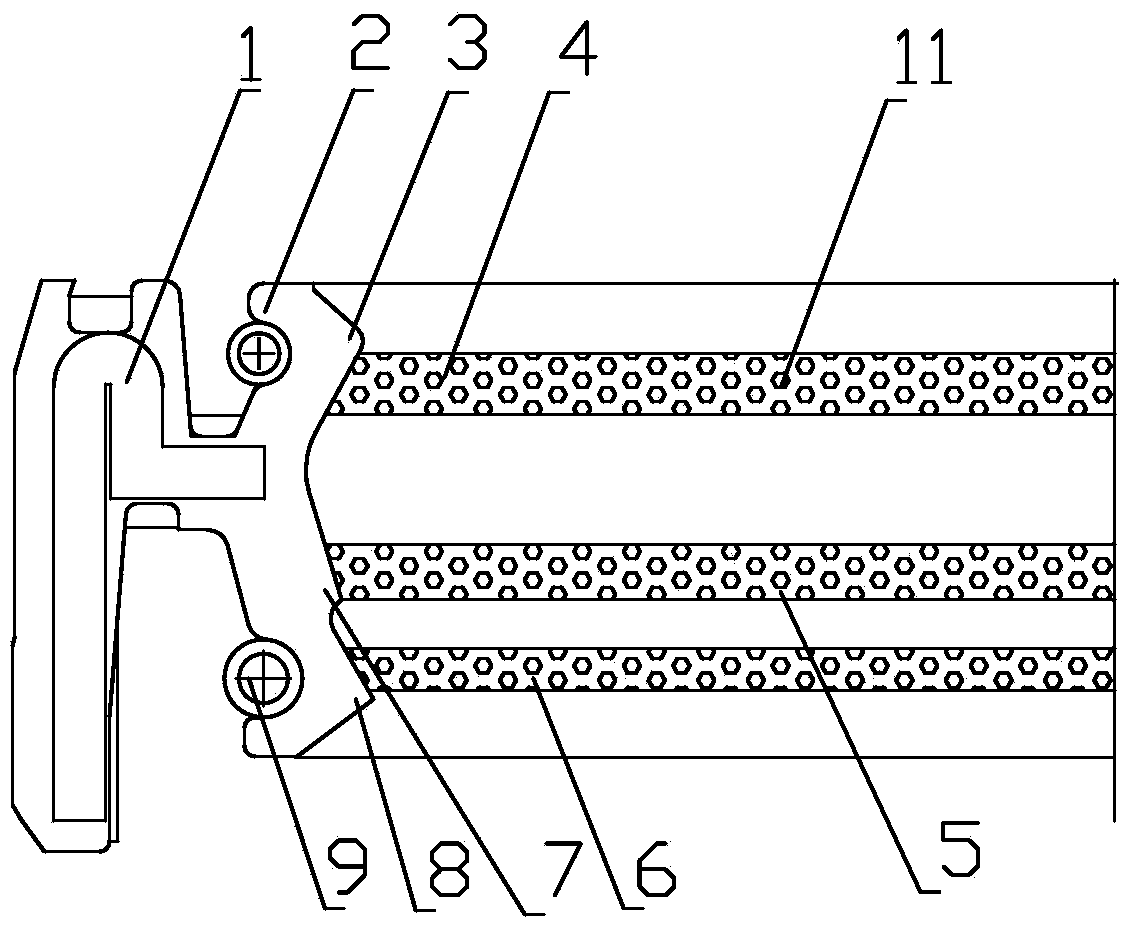

[0058] Such as image 3 with Figure 8 As shown, a low-friction reciprocating seal includes an annular support frame 1 and an annular elastic sealing body 2. The annular elastic sealing body 2 includes at least one sealing lip, and the annular sealing surface formed by the sealing lip is provided with The concave-convex surface ring belt is provided with a plurality of pits 11 .

[0059] The shape of the pit 11 is polygonal truncated.

[0060] The depth of the pit is 0.3mm.

[0061] The rest of the structures are as described above and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com