Automatic reactive torque balancing device for screw drill, drilling pipe string and method

A technology for automatic balancing and screw drilling tools, which is applied to drilling equipment and methods, drilling tools, drilling pipes, etc., which can solve the problems of expensive use and maintenance costs and lower drilling costs, and achieve low drilling and maintenance costs and improved Effect of ROP and Axial Friction Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

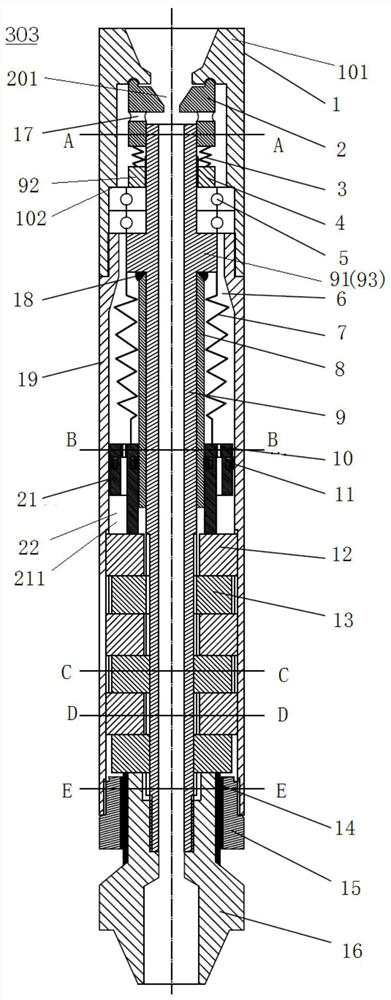

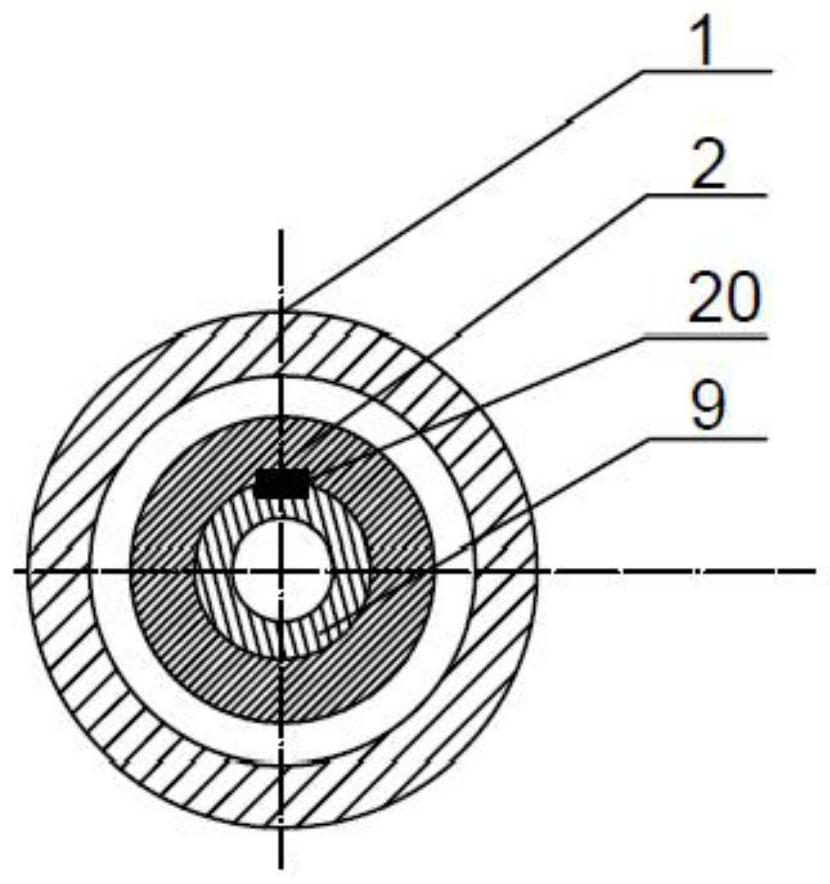

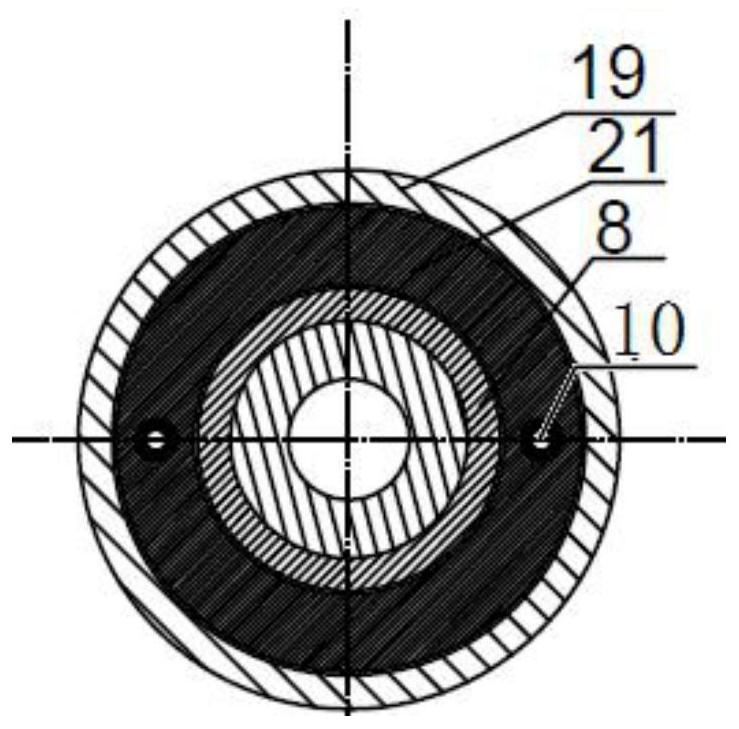

[0047] figure 1 An anti-torque automatic balancing device 303 for a screw drilling tool 305 according to one embodiment of the invention is shown. Such as figure 1 As shown, the anti-torque automatic balancing device 303 includes an upper joint 1, a lower joint 16, a core barrel 9 and an automatic balancing assembly. Among them, such as Figure 7As shown, the upper joint 1 is cylindrical and used to connect with the upper drill pipe 302 of the drilling string. The core tube 9 itself is also cylindrical, and is used to be arranged in the inner cavity of the upper joint 1 , and the inner cavity of the core tube 9 communicates with the inner cavity of the upper joint 1 . During the working process, the inner cavity of the core barrel 9 communicates with the downstream screw drilling tool 305, so that after the drilling fluid is pumped through the inner cavity of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com