Composite impactor

A technology of impactor and axial impact, which is applied in earthwork drilling, driving devices for drilling in boreholes, drilling equipment, etc., and can solve problems such as stick-slip of the drill string system, reduced drilling efficiency, and low ROP. Achieve the effects of not being easy to fail, reducing stick-slip phenomenon, and increasing ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

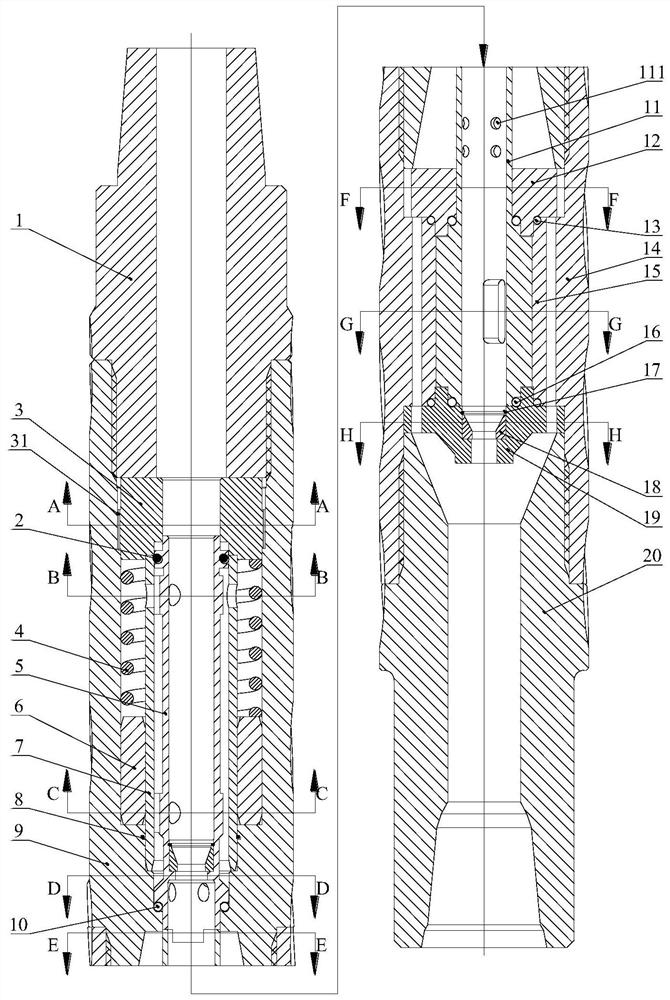

[0030] The present invention will be further described below in conjunction with accompanying drawing.

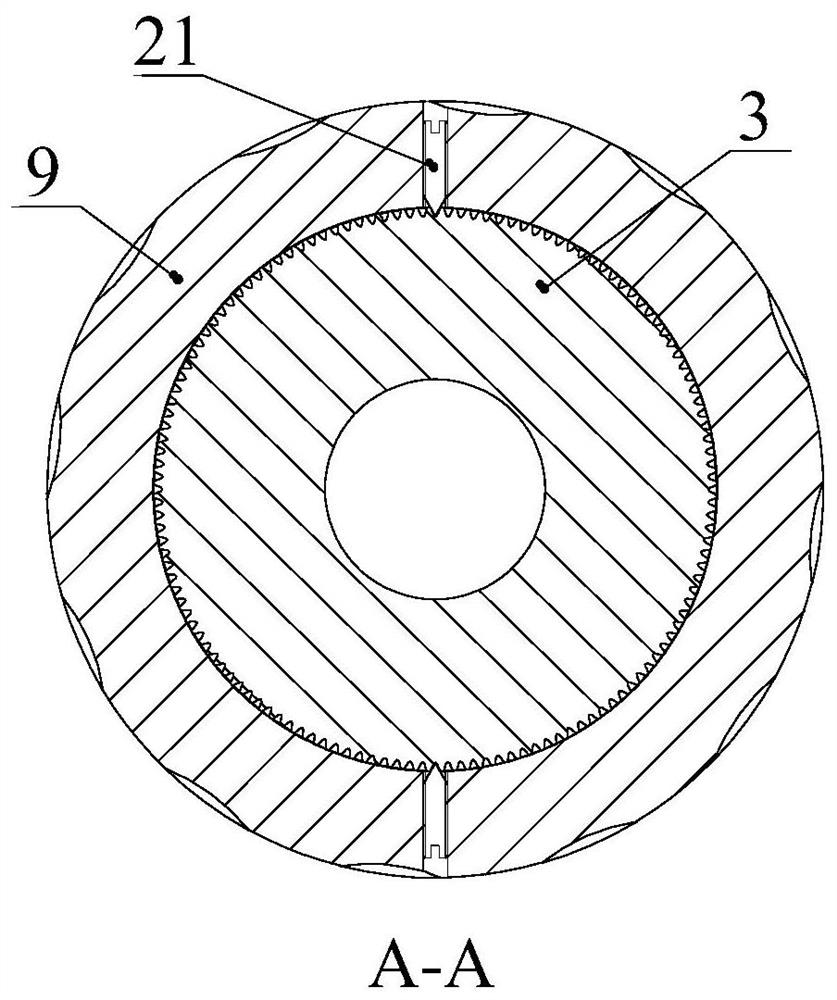

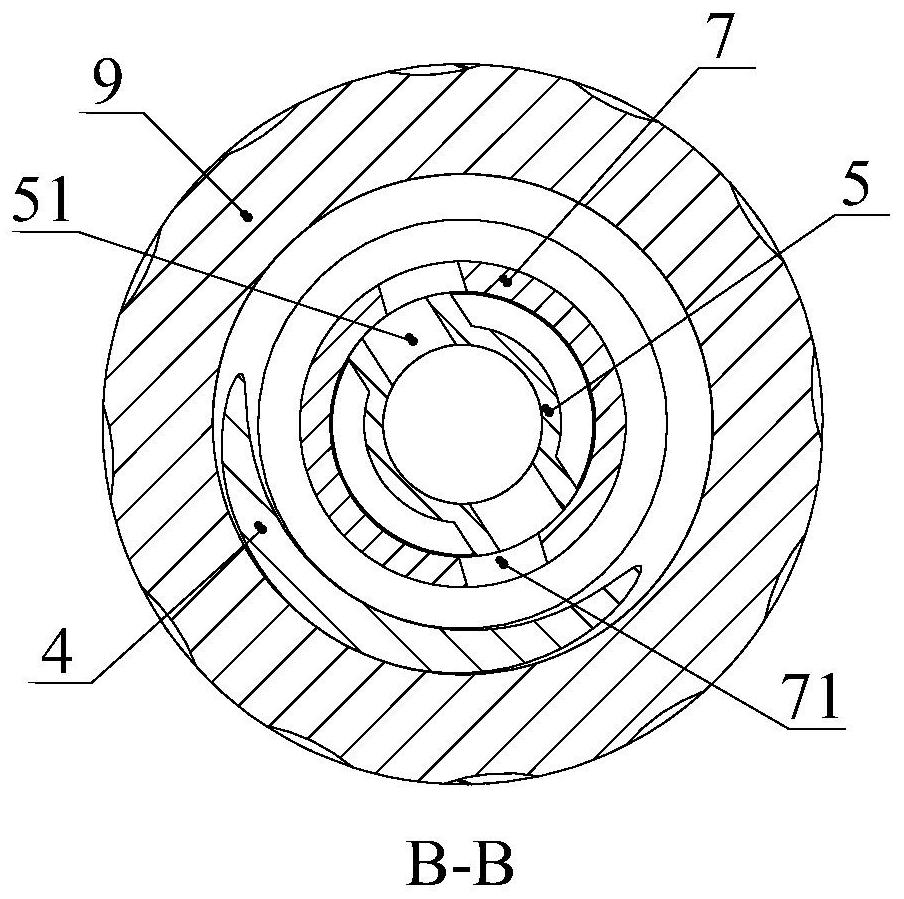

[0031] figure 1 A composite impactor according to one embodiment of the present invention is schematically shown. It should be noted that the accompanying drawings of the present invention apply it to oil drilling, and it is not limited to this application only. Take the application in oil drilling as an example below. The two ends of the composite impactor are connected by threads, which is convenient for disassembly and assembly; the axial impact part of the composite impactor includes the impact hammer 6 located inside the upper shell 9, the center tube 5 and the middle tube 7 for moving and reversing the hammer 6, The fixed block 3 inserted on the upper end of the intermediate tube 7, the adjustment screw 21 assembled on the upper casing 9, and the spring 4 located between the fixed block 3 and the hammer 6; the hammer 6 of the axial impact part reciprocates up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com