Reciprocating percussive-rotary drilling tool

A rotary drilling and reciprocating technology, which is applied in the field of geological exploration hole drilling engineering, can solve the problems of drill string torsional vibration, drill sticking, drill bit, and adverse effects on the service life of drill string supporting parts, so as to improve rock breaking efficiency and improve ROP and the effect of reducing the stick-slip phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

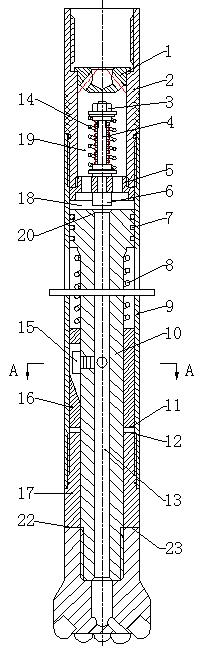

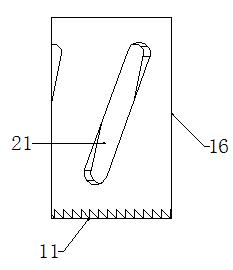

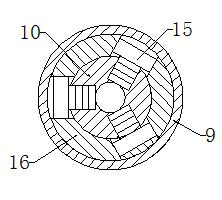

[0011] Such as figure 1 , figure 2 , image 3 As shown, a reciprocating impact rotary drilling tool of the present invention is composed of a flow controller 1, an upper joint 2, an automatic valve device 19, a casing 9, a mandrel 10, a rotating device 16, and a load-bearing joint 17. Its structural features are: the upper joint 2 is connected to the upper part of the shell 9 through threads, and a flow controller 1 is installed inside; the automatic valve device 19 is installed in the upper joint 2, and the automatic valve device 19 is composed of the valve stroke calibration device 3 and the valve stem 4 , a valve body 5, a valve head 6, and a valve spring 14, which together with the upper end surface of the shell 9 and the mandrel 10 form a variable volume chamber 18; There is a seal 7 between the two; there are three spiral grooves 21 on the rotating device 16, and there is a unidirectional lower pawl surface 11 on the lower end surface, and the cylindrical follower 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com