A Method Of And A Device And An Electronic Controller For Mitigating Stick-slip Oscillations In Borehole Equipment

A technology of electronic controller and drilling equipment, which is applied in the direction of mechanical vibration control, drilling automatic control system, drilling equipment, etc., can solve the problems of sinusoidal waveform approximation and the inability to correctly describe the physical behavior of drilling equipment, etc. Stick-slip, the effect of reducing stick-slip oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

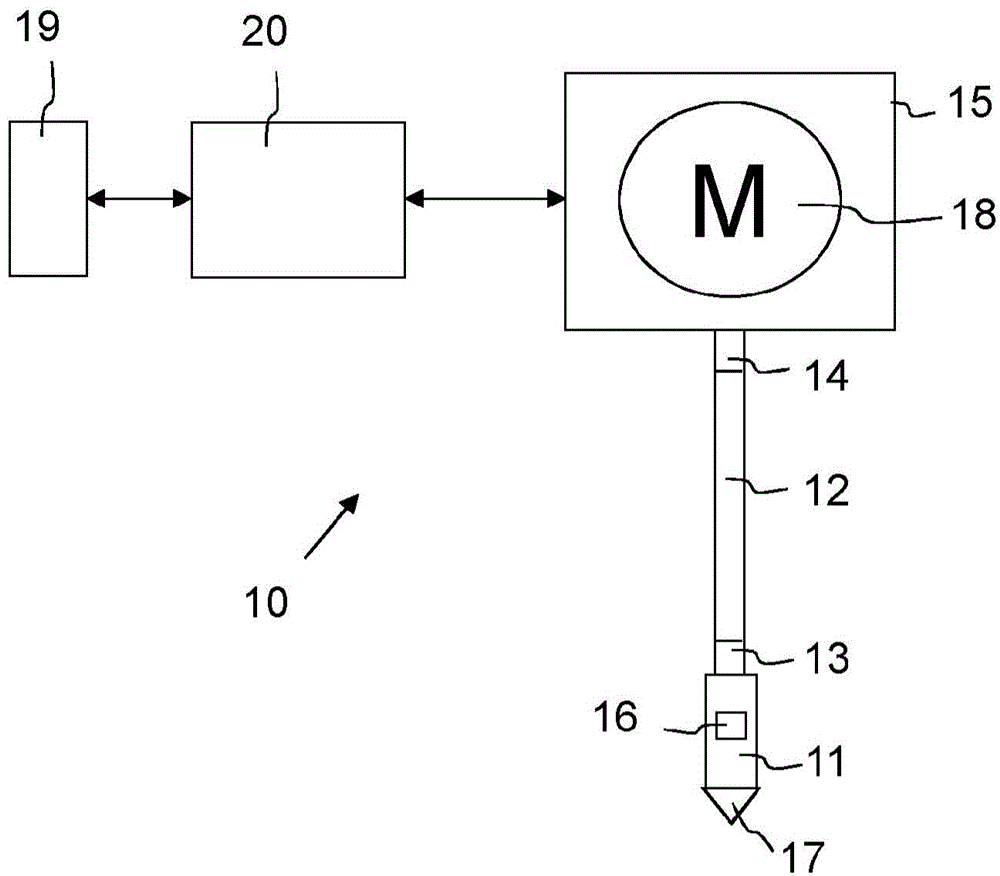

[0081] figure 1A typical drilling rig 10 of a drilling rig for drilling boreholes in earth formations is shown in a schematic manner. The cutting tool used to drill these boreholes is called a drill bit 17 and is connected to the bottom hole assembly BHA11 at the bottom end face 13 of the drill wire 12 . At the top end face 14 of the drilling line, the drilling line 12 is coupled to a rotary drive system 15 .

[0082] Borehole string 12 comprises a length of hollow tubular or borehole pipe threaded together end-to-end. Typical borehole cables are several kilometers long, eg 0-10 km, and borehole pipes may have an outer diameter of about 100-300 mm and a wall thickness of about 10-50 mm. The BHA11 comprises a heavier pipe, which may have an outer diameter of about 250-500 mm and a wall thickness of about 100 mm, for example called a drill collar. The length of the BHA is typically in the range of 100-300m. The drilling string 12 is very slender compared to its length.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com