Downhole gas phase space rotary swing drilling tool and implementation method thereof

A gas-phase space, drilling tool technology, applied in the direction of drilling with vibration, can solve the problems of reducing drilling speed and footage, sticking, affecting directional construction, etc., to reduce drag and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

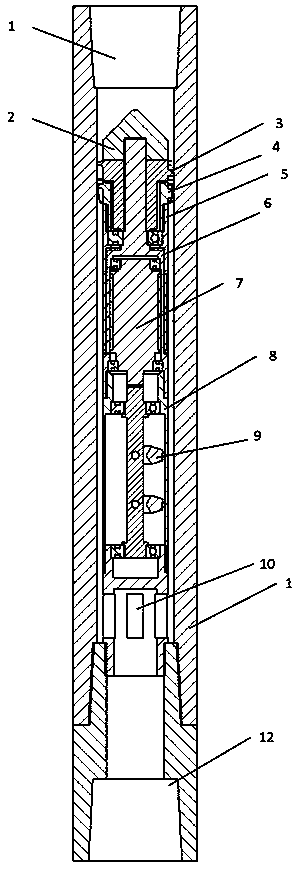

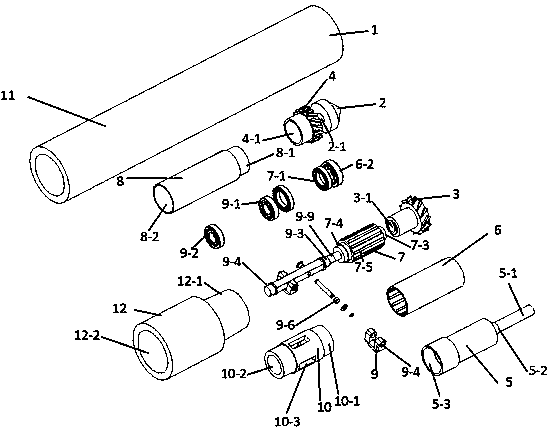

[0009] Such as figure 1 , 2 As shown, a downhole gas-phase space rotary oscillating drilling tool includes a mud inlet 1, a liquid separator cover 2, a liquid separator wheel 3, a turbine 4, a coupling cylinder 5, a magnetic coupling rotor 6, a coupling inner shaft 7, and a pendulum cylinder 8 , Pendulum 9, return joint 10, outer cylinder 11, lower joint 12.

[0010] The liquid separation wheel 3 is sequentially connected to the external thread 5-1 on the upper part of the coupling cylinder 5 through the internal thread 3-1, and the liquid separation cover 2 is connected to the external thread 5-1 on the upper part of the coupling cylinder 5 through the internal thread 3-1, and the liquid separation cover 2 is pressed against the upper surface of the liquid separation wheel 3, The outer ring of the magnetic coupling rotor bearing 6-2 is clamped in the magnetic coupling rotor 6, and the inner ring is fixed on the clamping shaft 5-2 of the coupling cylinder 5, and the turbine 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com