Method and apparatus for applying vibrations during borehole operations

a technology of vibration and operation, applied in the direction of drilling machine and method, borehole/well accessories, drilling accessories, etc., can solve the problems of increased axial friction, no longer helping gravity, and difficult access, so as to ease any torsion forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

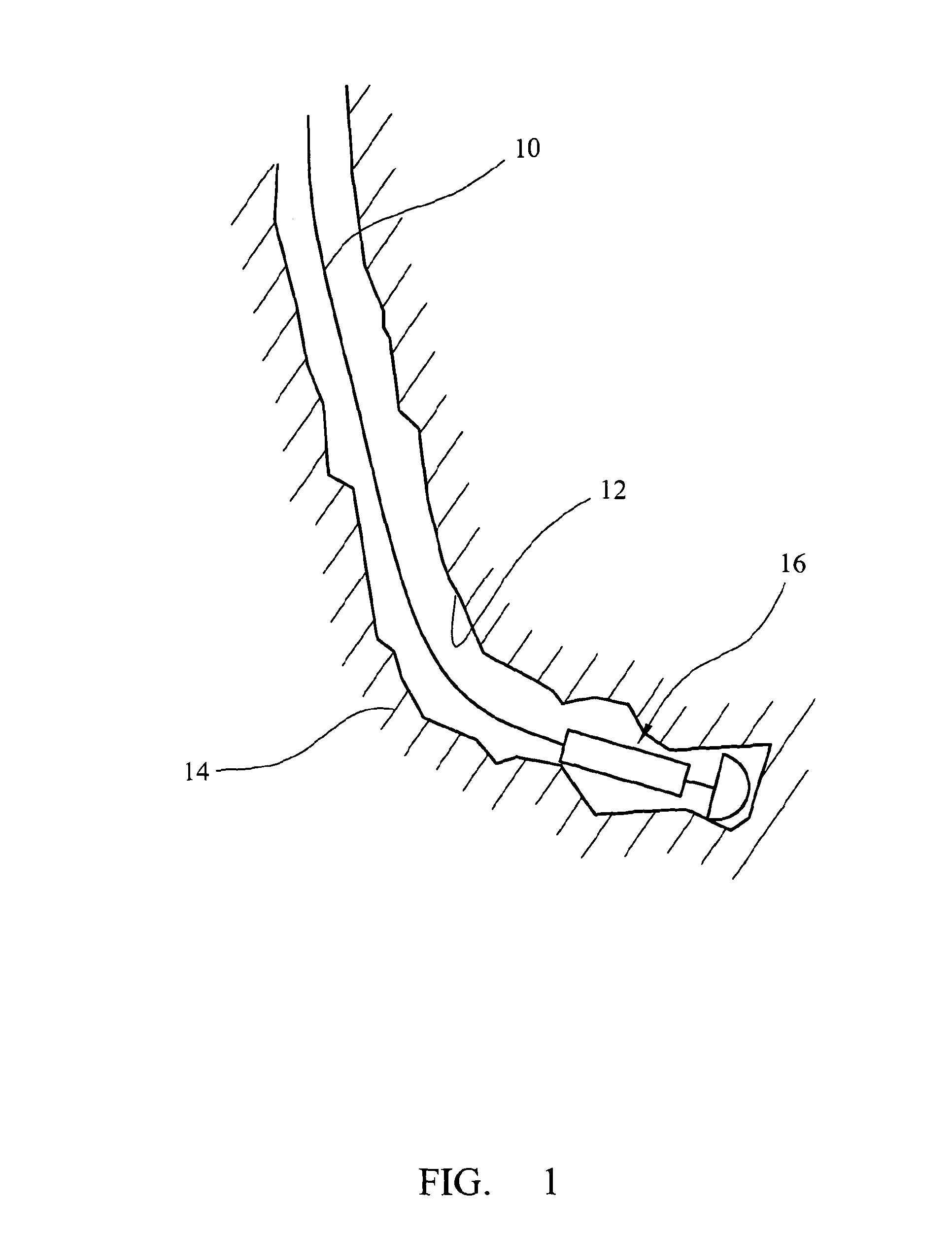

[0040]The invention will be described in relation to a coiled tubing drilling operation. However, it will be apparent that it can apply to other forms of drilling or well operations. For example, the benefit of the invention can be obtained in drilling with conventional drill pipe, especially when it is operating in sliding mode such as in directional drilling applications. Also, a similar benefit can be obtained with other operations where it is necessary to advance a downhole tool into the well using CT or drill pipe. Other applications involve running in casing, production or completion tubing, expandable tubulars, fishing operations, and wireline logging and drilling operations.

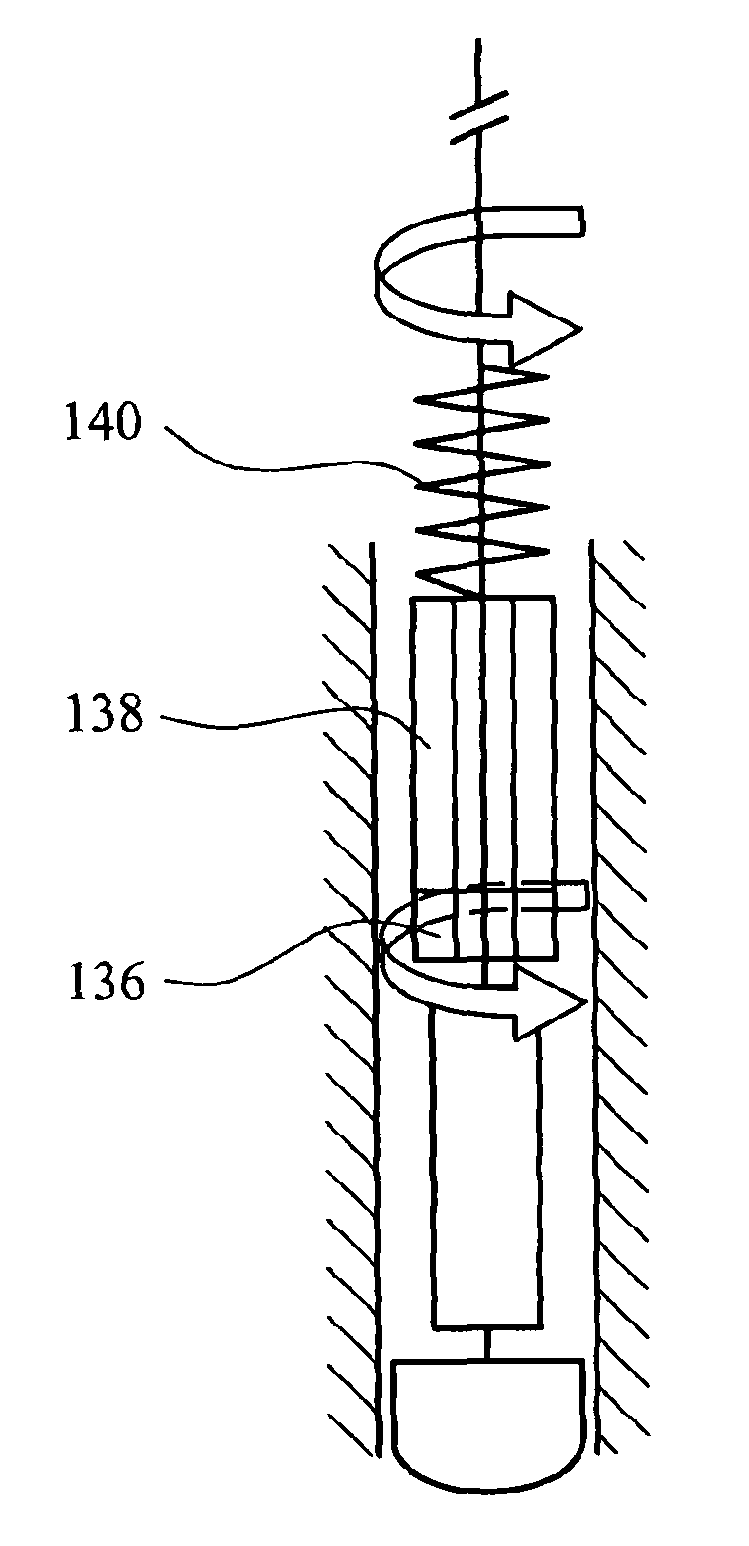

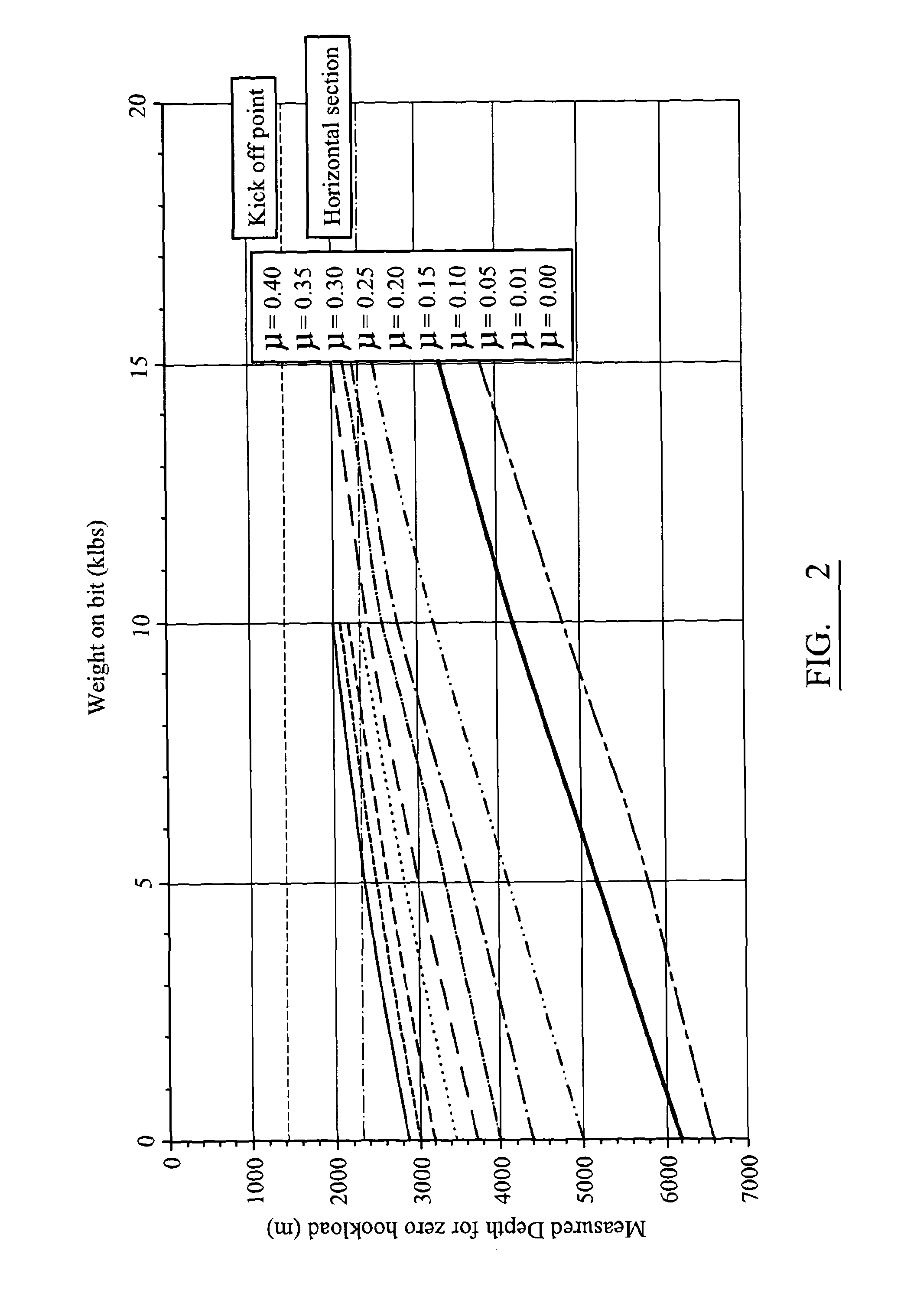

[0041]In order to avoid the problems of axial friction (drag) associated with the prior art systems discussed above, torsional vibrations are applied to the drill string (or tool string) in order to move the friction from the static domain to dynamic domain, and to change the friction vector from axial to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com