Cable-piercing hydraulic oscillator

A hydraulic oscillator and cable technology, which is applied in vibration drilling, drilling equipment, earthwork drilling and production, etc., can solve problems such as difficulty, high friction, and high cost, and achieve improved sealing performance, flexible relative movement, and prevention of relative rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

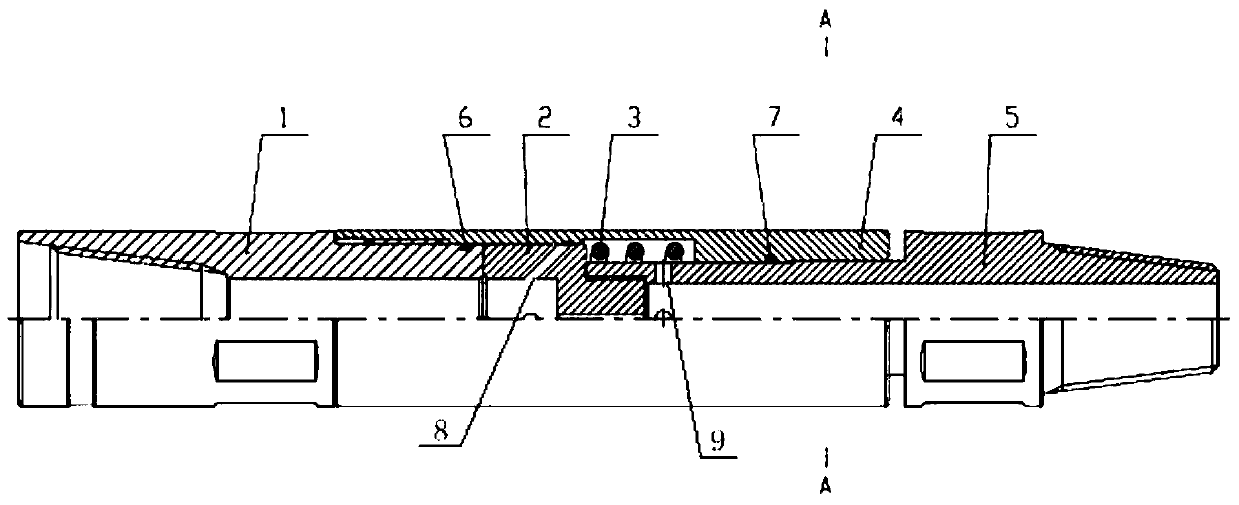

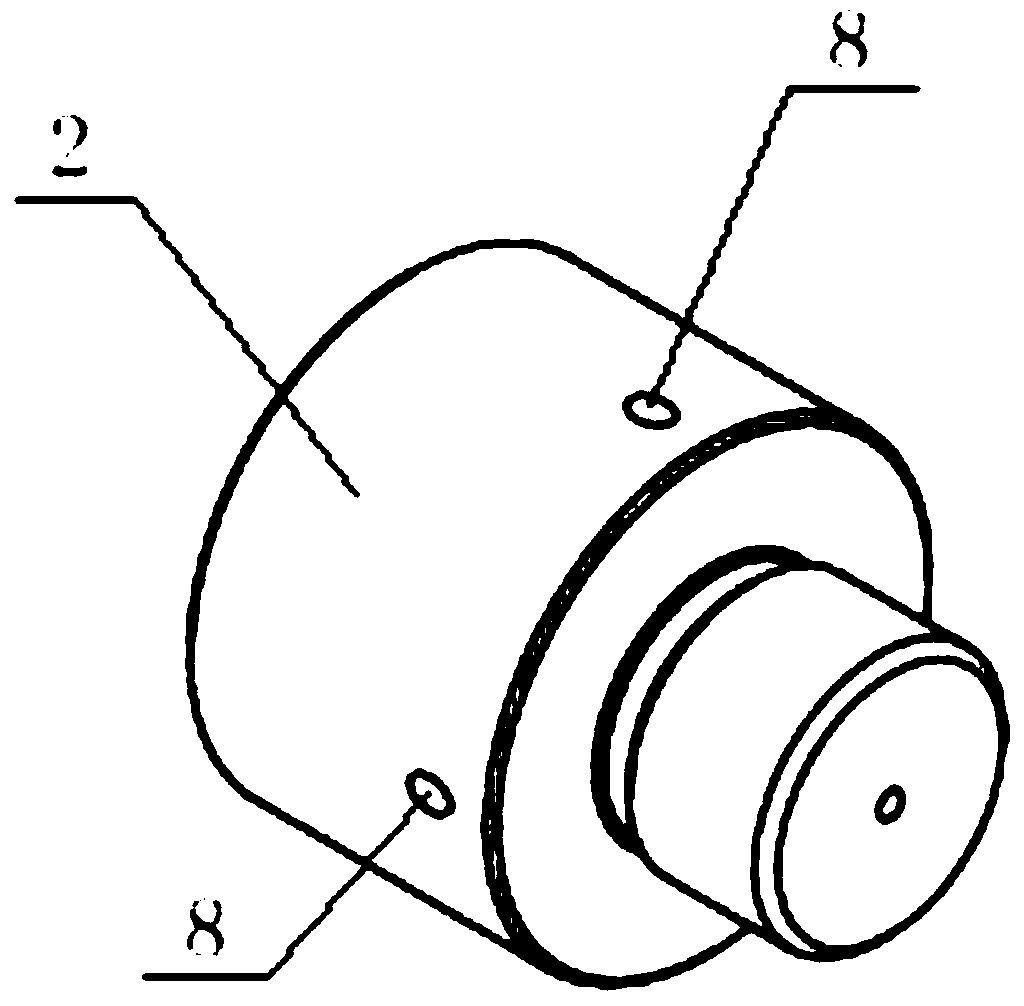

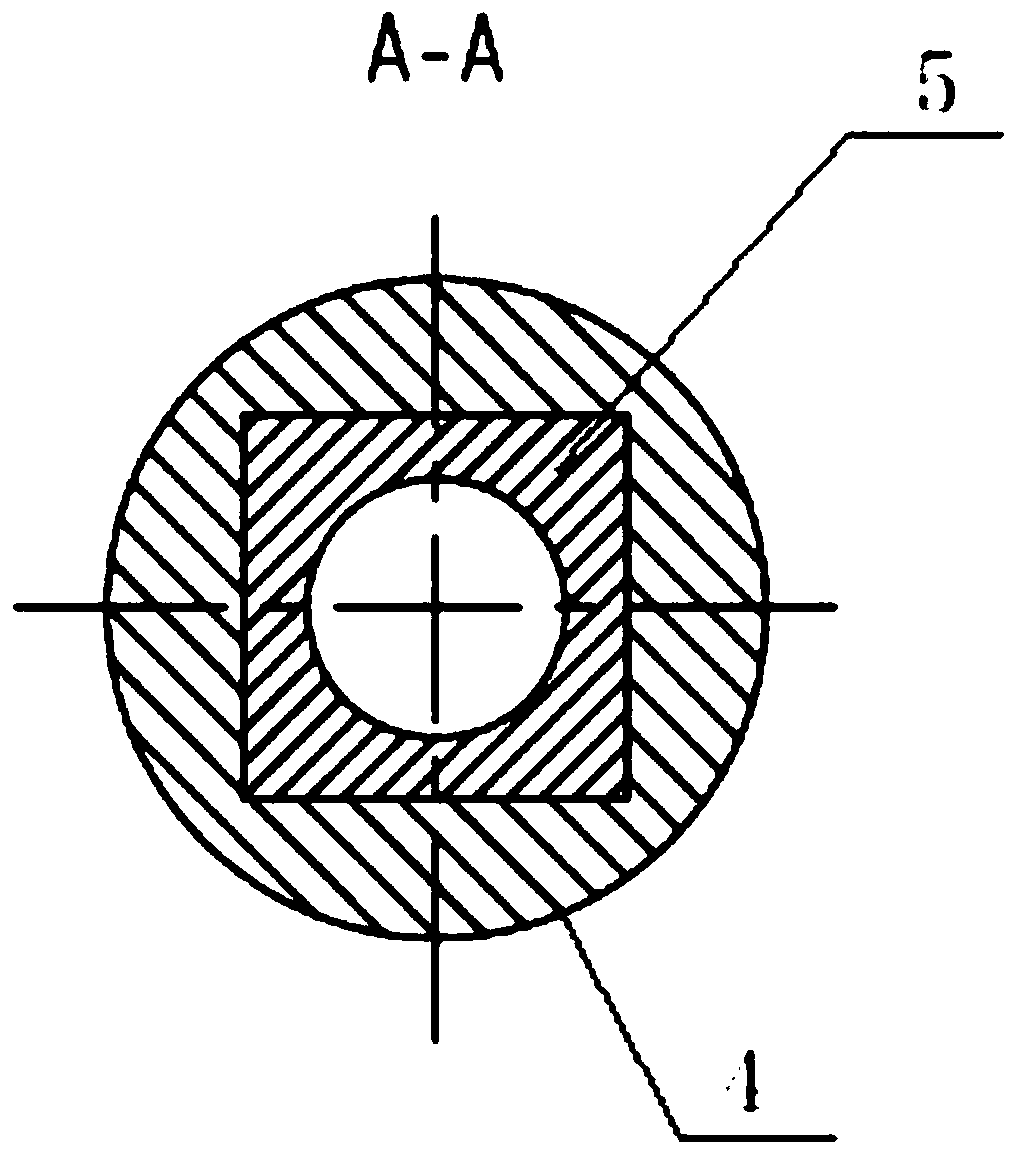

[0023] Examples such as Figures 1 to 2 As shown in Fig. 1, a cable-through hydraulic oscillator can be used for both oil and gas and coal gas exploitation. It includes an upper joint 1, a piston 2, a compression spring 3, an outer sleeve 4, a lower joint 5, a first sealing assembly 6 and a second sealing assembly 7, the upper joint 1 and the lower joint 5 are connected through the outer sleeve 4, specifically, the The outer jacket 4 is threadedly connected with the upper joint 1 . The outer casing 4 is arranged outside the upper joint 1 and the lower joint 5, the piston 2 is arranged inside the outer casing 4, the upper end of the piston 2 is arranged between the upper joint 1 and the lower joint 5, and the lower end of the piston 2 is arranged at the lower joint. 5, and is connected with the lower joint 5, and the piston 2 is threaded with the lower joint 5. An annular cavity is enclosed between the outer casing 4, the piston 2 and the lower joint 5, and the compression sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com