Iron mine sintering binding phase high-temperature wettability measuring method

A measurement method and a binder phase technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the controversy over the guiding significance of the sintering process, and achieve the effects of short experiment period, simple measurement method, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

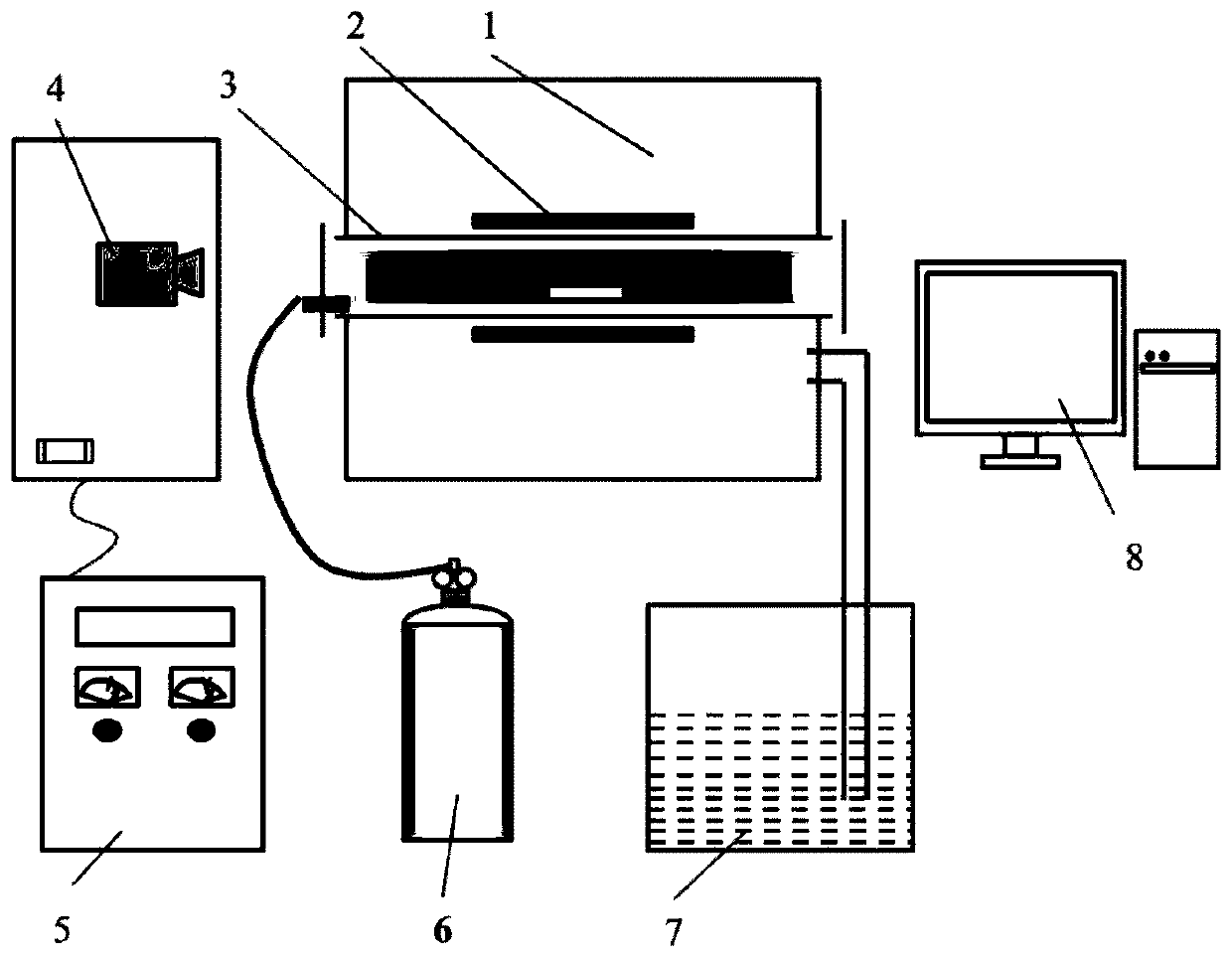

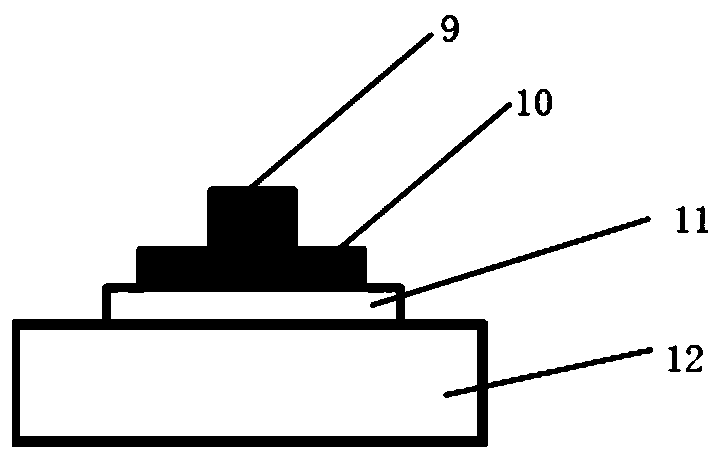

Method used

Image

Examples

Embodiment

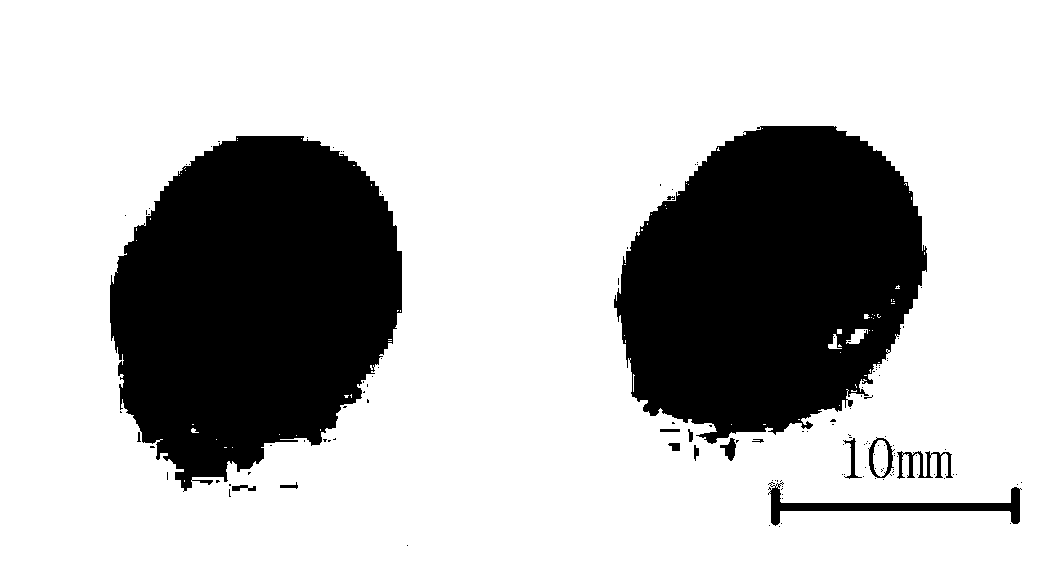

[0062] According to the above steps, Fe 2 o 3 -CaO-SiO 2 The ternary system binder phase is taken as an example, and the benchmark sample Fe 2 o 3 , CaO, SiO 2 The content ratio is 7:2:1, and the influence of the change of each component on the high temperature wettability of the binder phase is studied.

[0063] Table 1 Fe 2 o 3 Fe 2 o 3 -CaO-SiO 2 Variation of Contact Angle of Binder Phase in Ternary System

[0064]

[0065] Control system CaO and SiO 2 The mass ratio is constant, 2:1. It was found that with the system Fe 2 o 3 The content increases from 65wt.% to 85wt.%, and the complete liquid phase formation temperature of the system increases gradually, from 1304°C to 1467°C. According to the experimental requirements, the experimental temperature was selected as shown in Table 1. Fe 2 o 3 When the component content is 65wt.%, 70wt.%, 75wt.%, 80wt.%, 85wt.%, the corresponding contact angle measurements are 34°, 47°, 60°, 66°, 70°, with the Fe 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com