Special flat floating fixture for precision honing machine

A floating fixture and grinding machine technology, used in honing machine tools, manufacturing tools, grinding workpiece supports, etc., can solve problems such as uneven distribution of clamping force, failure to meet workpiece processing requirements, and unstable workpiece clamping. Achieve the effect of changing the uneven distribution of the pressing force, improving the machining accuracy, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

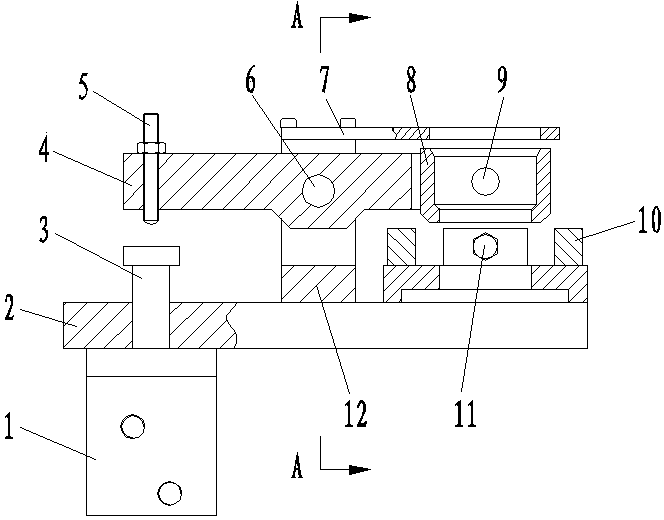

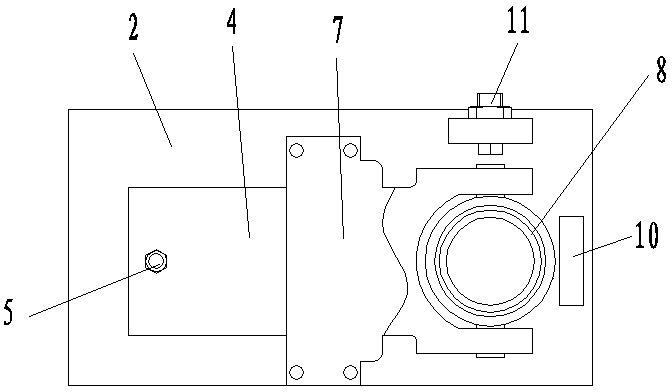

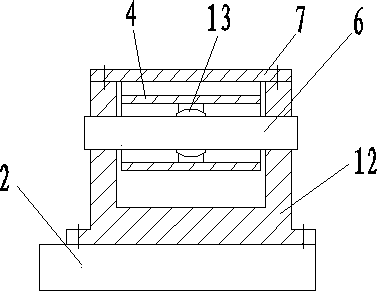

[0018] Such as figure 1 , 2 , 3, a support base 12 is fixedly installed on the fixture base 2, the middle part of the lever 4 is connected with the support base through the connecting shaft 6 and the joint bearing installed on the connecting shaft, and a U-shaped groove is opened at the right end of the lever. The cylindrical guide compression sleeve 8 is installed in the U-shaped groove through two symmetrical pin shafts 9 fixed on its outer surface, and a compression cylinder 1 is installed on the clamp base at the lower left end of the lever. An adjusting screw 5 is installed at the top corresponding position of the piston rod 3 in the oil cylinder.

[0019] An elastic orifice 7 is fixed on the upper end face of the support seat, the hole on the elastic orifice is concentric with the inner hole of the cylindrical guide compression sleeve, and the aperture on the elastic orifice is greater than the inner hole of the cylindrical guide compression sleeve. Three positioning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com