Energy-saving low-radiation glass vertical-type magnetron sputtering production device

A low-emissivity glass and magnetron sputtering technology, applied in the field of energy-saving low-emissivity glass production equipment, can solve the problems of insufficient quality of low-emissivity glass, and achieve the effect of firm and reliable adhesion and uniform film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings.

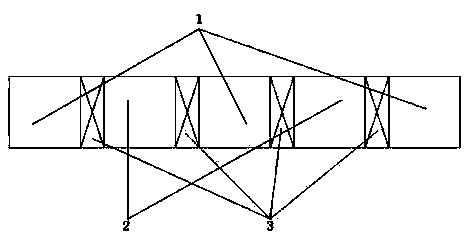

[0017] like figure 1 As shown, an energy-saving low-emissivity glass vertical magnetron sputtering production equipment includes a coating cavity unit 1 . A process isolation cavity 2 is arranged between the plurality of coating cavity units 1 . An isolation valve is arranged between the coating cavity unit 1 and the process isolation cavity 2 . The process isolation chamber 2 is used for isolation between the coating chamber units 1, and there are no special requirements on the structure.

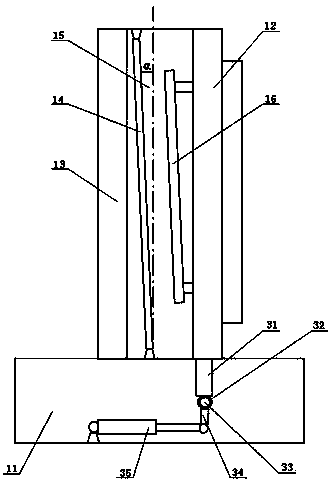

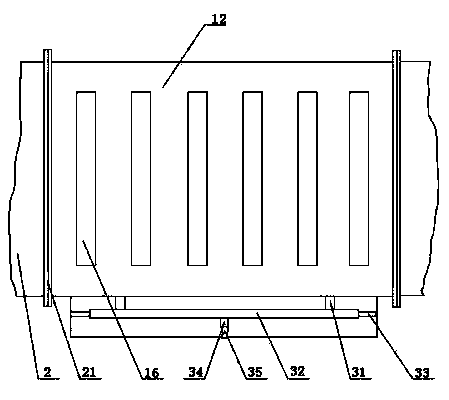

[0018] Coating cavity unit 1, such as figure 2 , image 3 As shown, it includes: a base 11 , a target frame 12 , a back plate base 13 , and a glass frame 14 . The target frame 12 and the back plate seat 13 are mounted on the base 11 to enclose a coating cavity 15 . The coating chamber 15 and the isolation valve 2 are sealed by the sealing flange 21 . The target hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com