Electron transport material ink for ink-jet printing, and preparation method and application thereof

An electronic transmission material and inkjet printing technology, applied in applications, inks, circuits, etc., can solve problems such as uneven film thickness, achieve the effects of reducing production costs, simple production process, and suppressing the formation of coffee rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

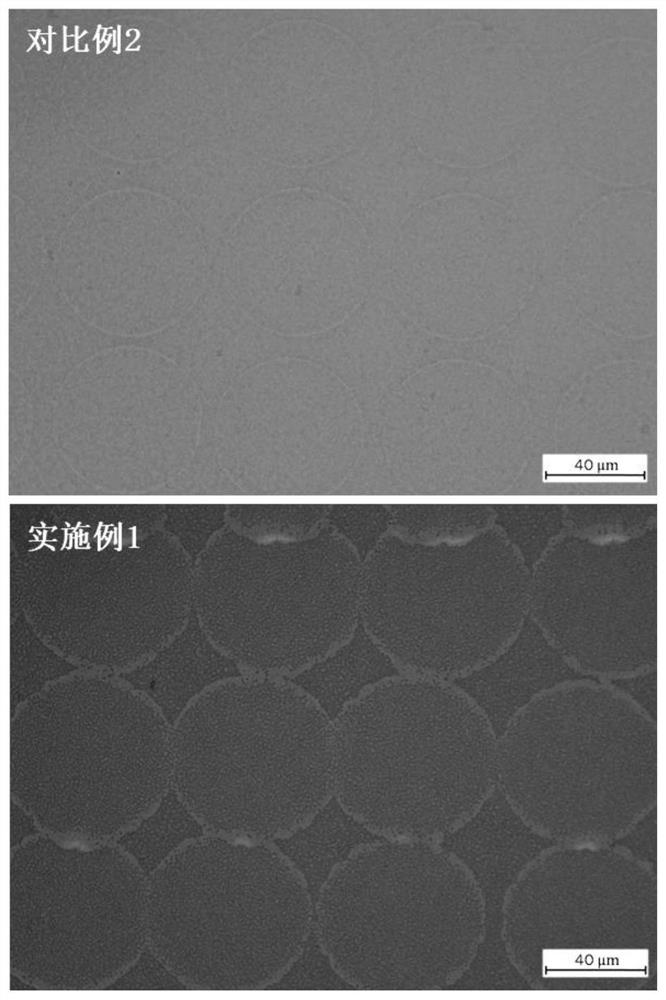

Embodiment 1

[0040] Hole transport layer solution preparation: the hole transport polymer polyvinylcarbazole (PVK) was dissolved in chlorobenzene solvent, the solution concentration was 10mg / mL.

[0041] Preparation of the light-emitting layer solution: the hole transport material 4,4,4,-tris(carbazol-9-yl)triphenylamine (TCTA), the electron transport material 2,6-bis((9H-carbazol-9-yl )-3,1-phenylene)pyridine (26DCzPPy) and the green phosphorescent dye tris(2-phenylpyridine)iridium(III)(Ir(ppy) 3 ) according to being dissolved in the chlorobenzene solvent in the mass ratio of 9:9:2, solution concentration 20mg / mL.

[0042] Electron transport material ink configuration: Dissolve 1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl)benzene (TPBi) in isopropanol:methanol mixed solution, solution ratio 50%:50 % (volume ratio), concentration 4mg / mL.

[0043] Preparation of hole transport layer, light emitting layer and electron transport layer:

[0044] First, ultrasonically treat the ITO glass substra...

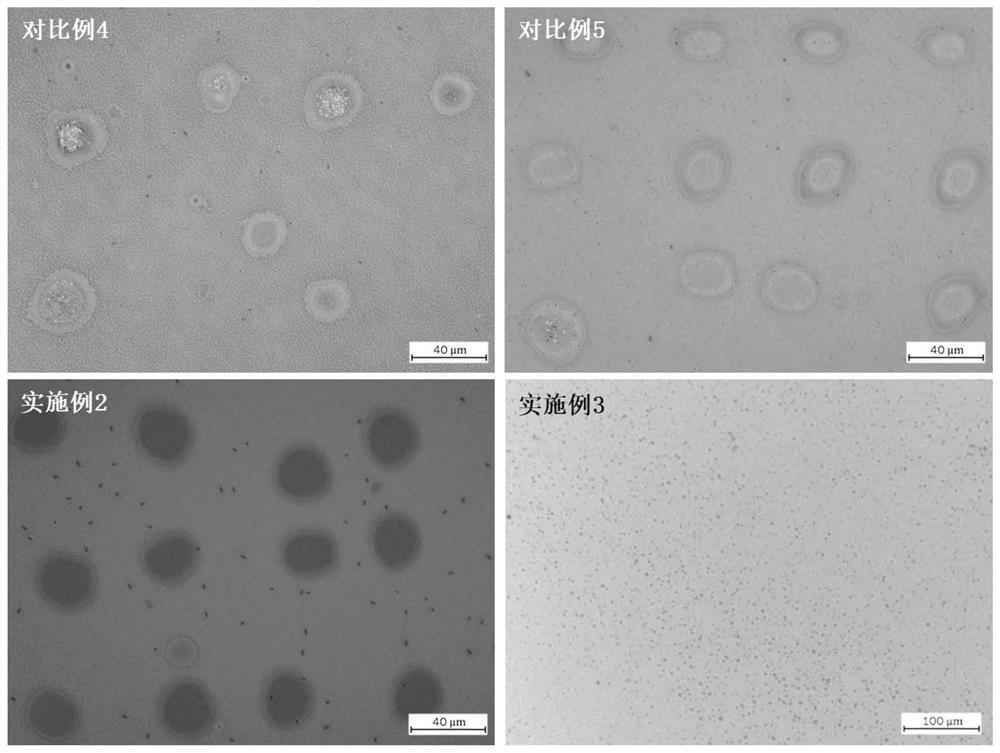

Embodiment 2

[0050] Preparation of the hole transport layer solution: Dissolve PVK in chlorobenzene solvent with a solution concentration of 10 mg / mL.

[0051] Preparation of luminescent layer solution: mix TCTA, 26DCzPPy and Ir(ppy) 3 Dissolve in chlorobenzene solvent according to the mass ratio of 9:9:2, solution concentration 20mg / mL.

[0052] Electron transport material ink configuration: TPBi was dissolved in methanol: ethylene glycol mixed solution, solution ratio 90%: 10% (volume ratio), concentration 8mg / mL.

[0053] Preparation of hole transport layer, light emitting layer and electron transport layer:

[0054] First, ultrasonically treat the ITO glass substrate in acetone, ethanol, and deionized water for 15 minutes in sequence, blow it dry with nitrogen, and place it in an oven at 120°C for drying;

[0055] Secondly, after 15 minutes of UVO treatment, spin-coat PEDOT:PSS solution at a speed of 2500rpm, spin-coat for 1 minute, and solidify the film at 120°C for 30 minutes, with...

Embodiment 3

[0060] Preparation of the hole transport layer solution: Dissolve PVK in chlorobenzene solvent with a solution concentration of 10 mg / mL.

[0061] Preparation of luminescent layer solution: mix TCTA, 26DCzPPy and Ir(ppy) 3 Dissolve in chlorobenzene solvent according to the mass ratio of 9:9:2, solution concentration 20mg / mL.

[0062] Electronic transport material ink configuration: TPBi was dissolved in methanol: ethylene glycol: polyethylene glycol octylphenyl ether mixed solution, solution ratio 90%: 10%: 0.15% (volume ratio), concentration 8mg / mL.

[0063] Preparation of hole transport layer, light emitting layer and electron transport layer:

[0064] First, ultrasonically treat the ITO glass substrate in acetone, ethanol, and deionized water for 15 minutes in sequence, blow it dry with nitrogen, and place it in an oven at 120°C for drying;

[0065] Secondly, after 15 minutes of UVO treatment, spin-coat PEDOT:PSS solution at a speed of 2500rpm, spin-coat for 1 minute, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com