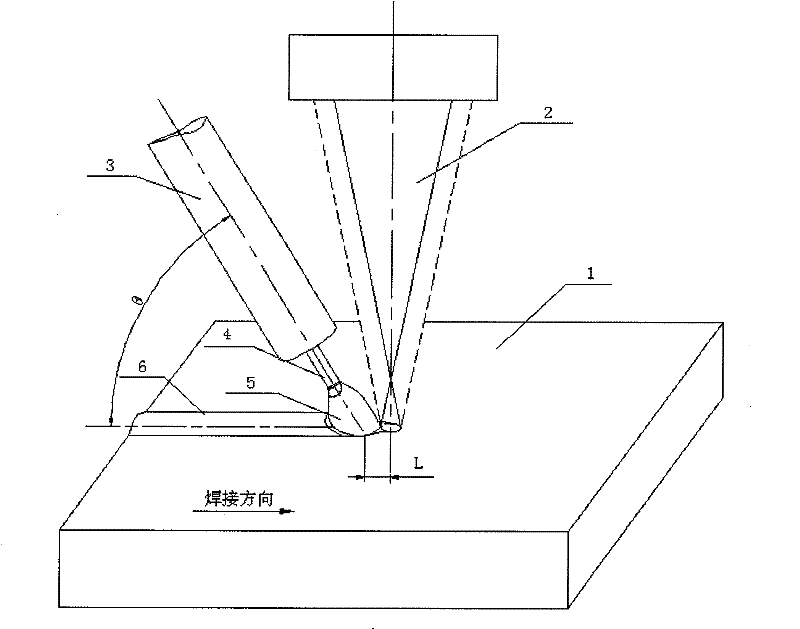

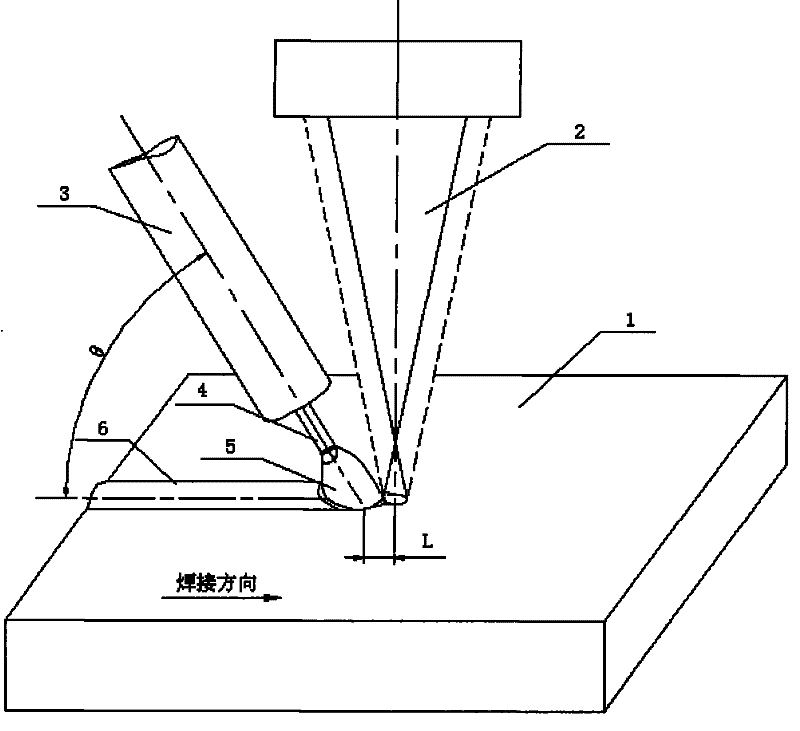

Method for welding with laser-cold metal transferred arc composite heat source

A technology of cold metal transition and composite heat source, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of lack of fusion, unstable welding process, and high welding seam, so as to improve stability and improve welding. Quality and welding efficiency, improved weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

[0024] Utilize a kind of laser-cold metal transitional arc composite heat source that the present invention proposes to carry out welding test, test adopts the HL2006D type Nd:YAG solid-state laser that German TRUMPF company produces, the maximum output power is 2.6KW, and output wavelength is the continuous light wave of 1.06 μm, adopts Focusing lens with a focal length of 200mm, CMT arc power supply is TPS4000 digital CMT welding power supply and wire feeding system produced by Austrian FRONIUS company.

[0025] 1. The base material of the test is 304 stainless steel, the size of the test plate is 200mm×40mm×7mm, 308L stainless steel welding wire with Ф1.2mm is used, the shielding gas is pure Ar, the gas flow rate is 25L / min, the test is flat surfacing, and the inspection after welding Weld forming.

[0026] The welding specification parameters are as follows:

[0027] The welding speed is 0.8m / min, the wire feeding speed is 6.6m / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com