Spray auxiliary for mechanized control engineering

A technology for spraying adjuvant and control engineering, applied in the application, insecticide, biocide and other directions, can solve the problems of easy volatilization, evaporation and poor spreadability of the liquid medicine, and solve the problems of liquid medicine settlement, surface tension reduction, chemical liquid The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

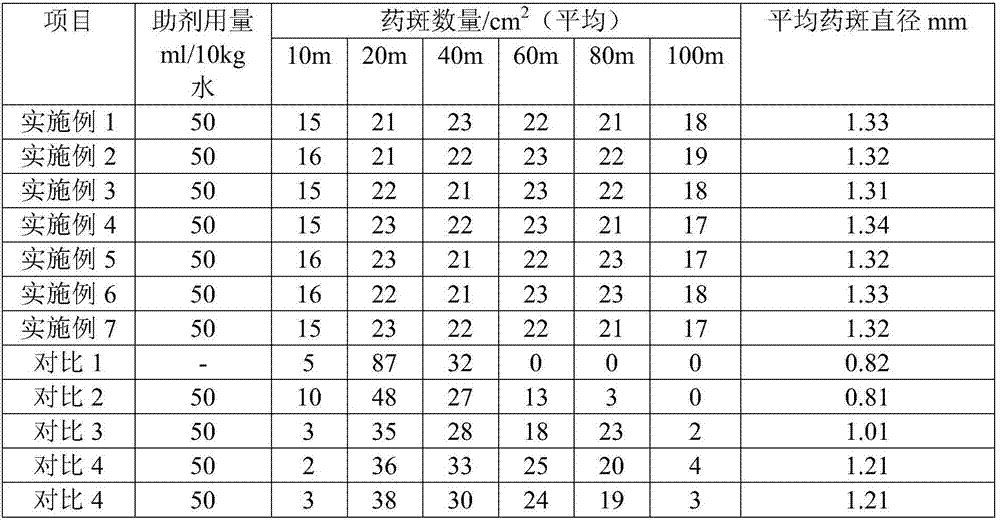

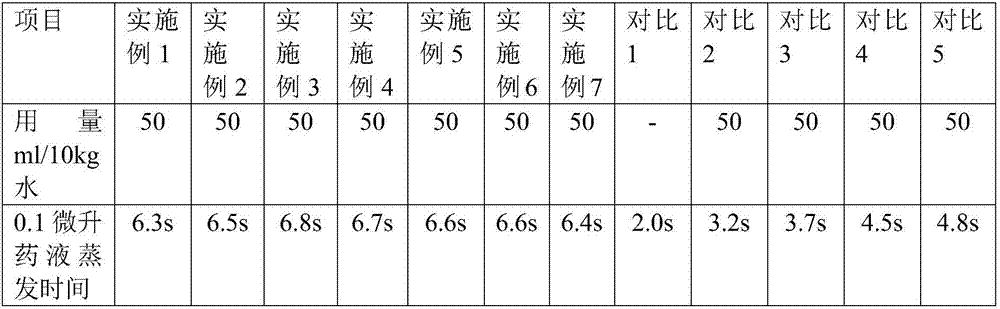

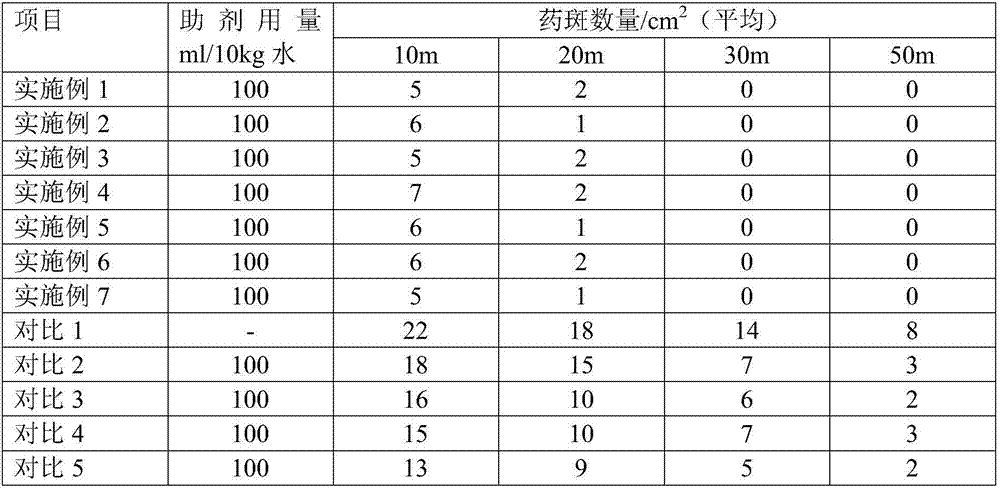

Examples

Embodiment 1

[0026] A spray additive for mechanized prevention and control engineering, comprising 10% mineral oil, 10% organic silicon, 5% polyethylene glycol dioleate, 5% polyethylene glycol glycerol linoleate, and The balance is methyl oleate of soybean oil.

Embodiment 2

[0028] The invention relates to a spray auxiliary agent for mechanized control engineering, which comprises 15% of mineral oil, 5% of organic silicon, 20% of sucrose erucate and the balance of corn oil in terms of mass percentage.

Embodiment 3

[0030] A spray additive for mechanized prevention and control engineering, comprising 20% of mineral oil, 15% of organic silicon, 10% of calcium dodecylbenzenesulfonate, 5% of fatty alcohol polyoxyethylene ether, and the balance of Methyl oleate of cottonseed oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com