Screw thread sealing method

A thread sealing and threading technology, which is applied to engine sealing, engine components, mechanical equipment, etc., can solve problems such as water leakage or oil leakage, poor sealing effect, and large waste of sealant, so as to improve the quality of glue application and Production efficiency, failure rate reduction, and the effect of reducing the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

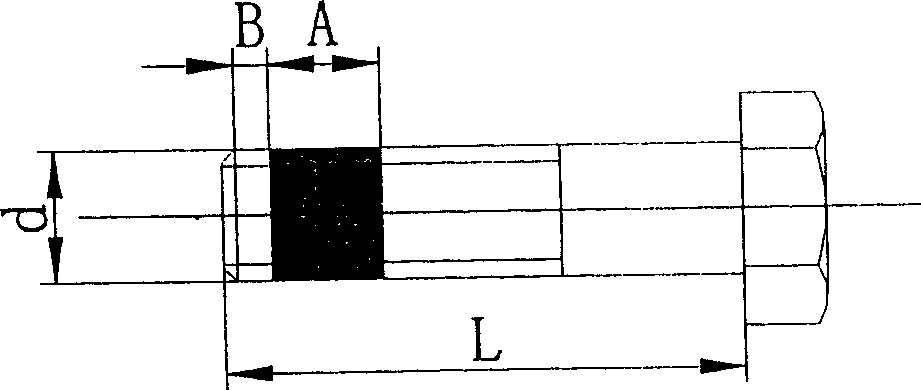

[0011] With reference to the accompanying drawings, the thread sealing method described in the embodiment comprises the following steps in turn:

[0012] A. Cleaning: Degrease the threaded part of the bolt to make the surface of the threaded part clean;

[0013] B. Pre-coating: In the specially set up gluing station, use a gluing machine or a professional operator to pre-coat DriLoc204 dry film anaerobic adhesive on the threaded joints cleaned in step A. The pre-coating length is A =1.2d-1.5d, the pre-applied glue position makes B equal to 1-2 screw pitches, and the amount of glue applied is to fill the grooves between the thread teeth to make the surface even;

[0014] C. Drying: Dry the pre-coated bolts at a temperature of 75°C-85°C for 25-30 minutes, and the thickness of the adhesive film after drying is 1 / 3-2 / 3 of the thread thread height ;

[0015] D. Installing: install the dried pre-glued bolts on the station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com