Preparation method of WO3/Ag/AgCl photocatalytic thin film material

A photocatalytic film and coating technology, applied in chemical instruments and methods, physical/chemical process catalysts, water/sludge/sewage treatment, etc., can solve problems such as unfavorable reuse, high cost, and time-consuming separation , to achieve the effects of easy recycling and reuse, good degradation performance, and easy catalytic phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 10.0g of tungstic acid and 5.0g of polyvinyl alcohol and add it to 20mL of hydrogen peroxide which is constantly stirred, and keep stirring for about 24h until the tungstic acid and polyvinyl alcohol are completely dissolved. The prepared solution was coated on the clean silicate glass surface, spin-coated at a speed of 800rmp for 8s with a homogenizer, then dried at 80°C for 1h, and then calcined at 550°C in a muffle furnace for 4h. Allow to cool naturally.

[0029] prepared WO 3 The optical physical picture of the film is shown in figure 1 As shown in a, it can be seen that a layer of nearly transparent film is attached to the glass surface; the prepared WO 3 SEM images of the film at different magnifications figure 2 (a and b), it can be seen that there is a layer of WO 3 The crystal particles are evenly attached to the surface of the glass.

Embodiment 2

[0031] Weigh 15.0g of tungstic acid and 5.0g of polyvinyl alcohol and add it to 20mL of 30% hydrogen peroxide with constant stirring, and keep stirring for about 24h until the tungstic acid and polyvinyl alcohol are completely dissolved. The prepared solution was coated on the clean silicate glass surface, spin-coated at 700rpm for 10s with a homogenizer, then dried at 80°C for 1h, and then calcined at 550°C in a muffle furnace for 6h. Allow to cool naturally. The prepared WO 3 The films were sequentially soaked in NaCl and AgNO at concentrations of 0.005M, 0.01M, and 0.02M, respectively. 3 solution for 30 minutes, repeat this step 3 times, and then irradiate it under a 300W xenon lamp for 10 minutes to obtain 1-WO 3 / Ag / AgCl film, 2-WO 3 / Ag / AgCl film, 3-WO 3 / Ag / AgCl film samples.

[0032] 1-WO 3 / Ag / AgCl film, 2-WO 3 / Ag / AgCl film, 3-WO 3 / Ag / AgCl thin film sample optical physical picture figure 1 (b,c,d), it can be seen that with NaCl and AgNO 3 As the concentrat...

Embodiment 3

[0034] Weigh 10.0g of tungstic acid and 5.0g of polyvinyl alcohol and add it into 30mL of 30% hydrogen peroxide which is constantly stirred, and keep stirring for about 24h until the tungstic acid and polyvinyl alcohol are completely dissolved. The prepared solution was coated on the clean silicate glass surface, spin-coated at 500rpm for 15s with a homogenizer, then dried at 80°C for 1h, and then calcined at 580°C for 5h in a muffle furnace. Allow to cool naturally. The prepared WO 3 The films were sequentially soaked in NaCl and AgNO at concentrations of 0.005M, 0.01M, and 0.02M, respectively. 3 solution for 30 minutes, repeat this step 3 times, and then irradiate it under a 300W xenon lamp for 10 minutes to obtain 1-WO 3 / Ag / AgCl film, 2-WO 3 / Ag / AgCl film, 3-WO 3 / Ag / AgCl film samples.

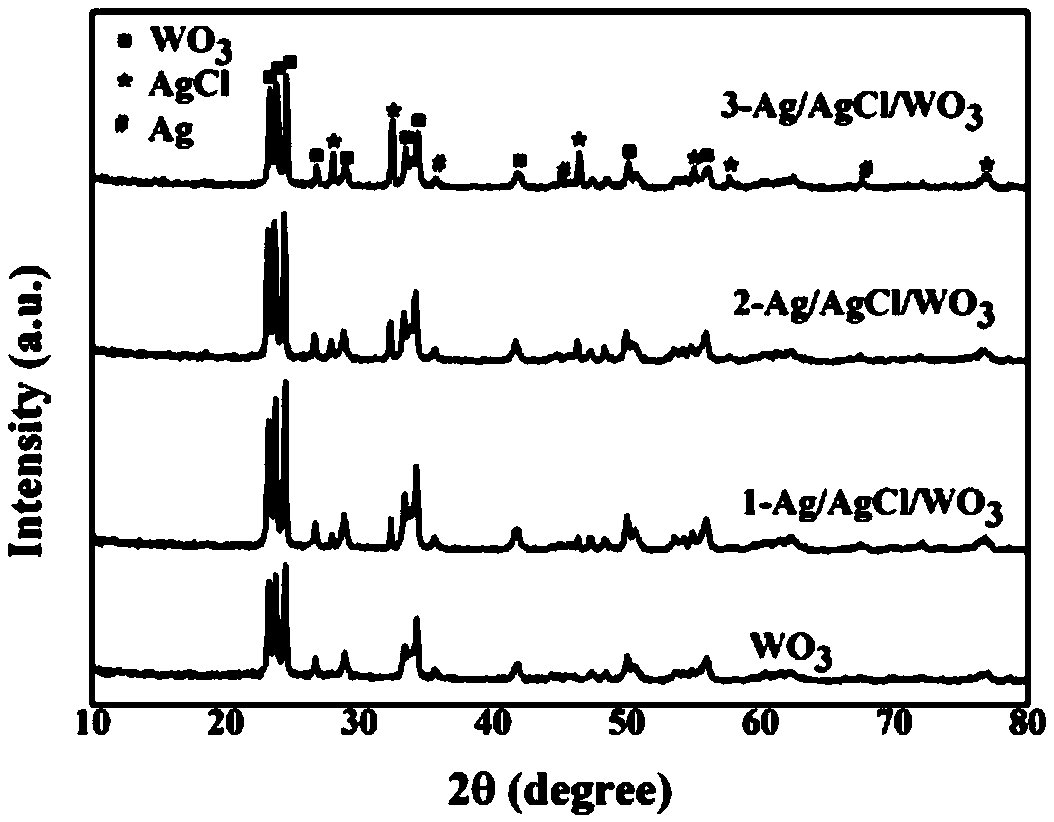

[0035] prepared WO 3 Film and 1-WO 3 / Ag / AgCl film, 2-WO 3 / Ag / AgCl film, 3-WO 3 The XRD pattern of / Ag / AgCl film is as follows image 3 , it can be clearly seen from the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com