Method for producing sodium stannate by using tin and tin alloy

A technology for producing sodium stannate and tin alloys, which is applied in the fields of tin compounds, chemical instruments and methods, and inorganic chemistry. It can solve the problems of unusable tin alloys, waste of resources and environment, and low tin content, so as to shorten the concentration time, High product quality, the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

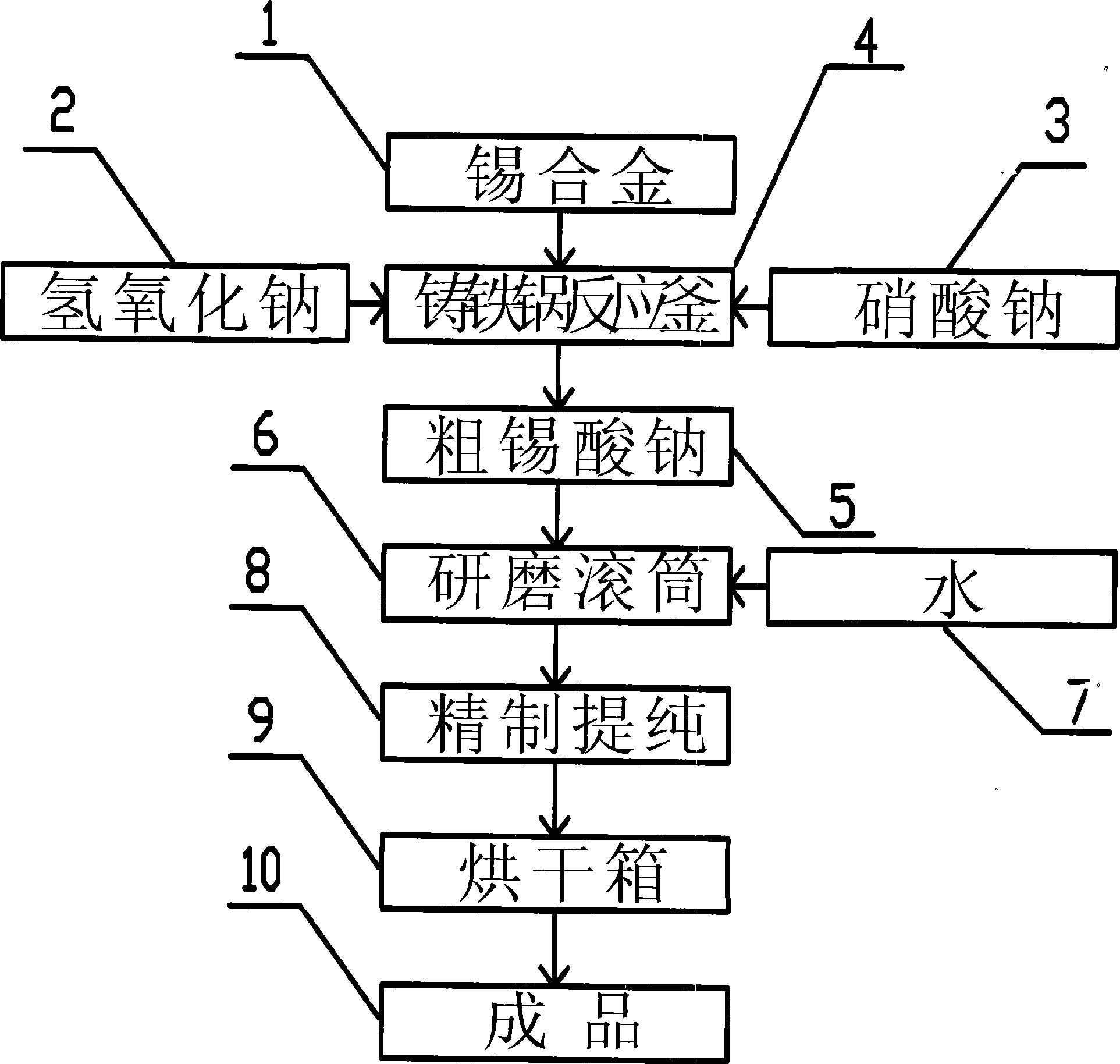

[0013] refer to figure 1 , figure 1 It is a schematic process flow diagram of an embodiment of a method for producing sodium stannate by using tin and tin alloys provided by the present invention: the chemical composition is: Pb30%, Sb10%, Sn36%, Si15%, Ag2500g / t, Au20g / t t, Cu9% tin alloy 1 is put into the cast iron pot reactor 4, gradually add sodium nitrate 3, sodium hydroxide 2 and the tin alloy 1 that have been melted to carry out chemical reaction in the cast iron pot reactor 4, stir during the reaction The thick sodium stannate 5 that generates is floated to the top of the cast iron pot reactor 4. The thick sodium stannate 5 is pulled out from the top of the cast iron pot reactor 4, and other metals left in the cast iron pot reactor 4 are flowed out for refining other metal materials; the thick stannic acid taken out from the cast iron pot reactor 4 Sodium 5 is placed in the grinding drum 6 and water 7 is added for grinding, and the crude sodium stannate 5 is dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com