Negative pressure magnetic stirring concentrator

A technology of magnetic stirring and concentrator, which is applied in the field of concentrator, can solve the problems of wasting high-purity nitrogen, polluting air, easy leakage cost, etc., and achieve the effect of reducing concentration time, reducing pollution and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

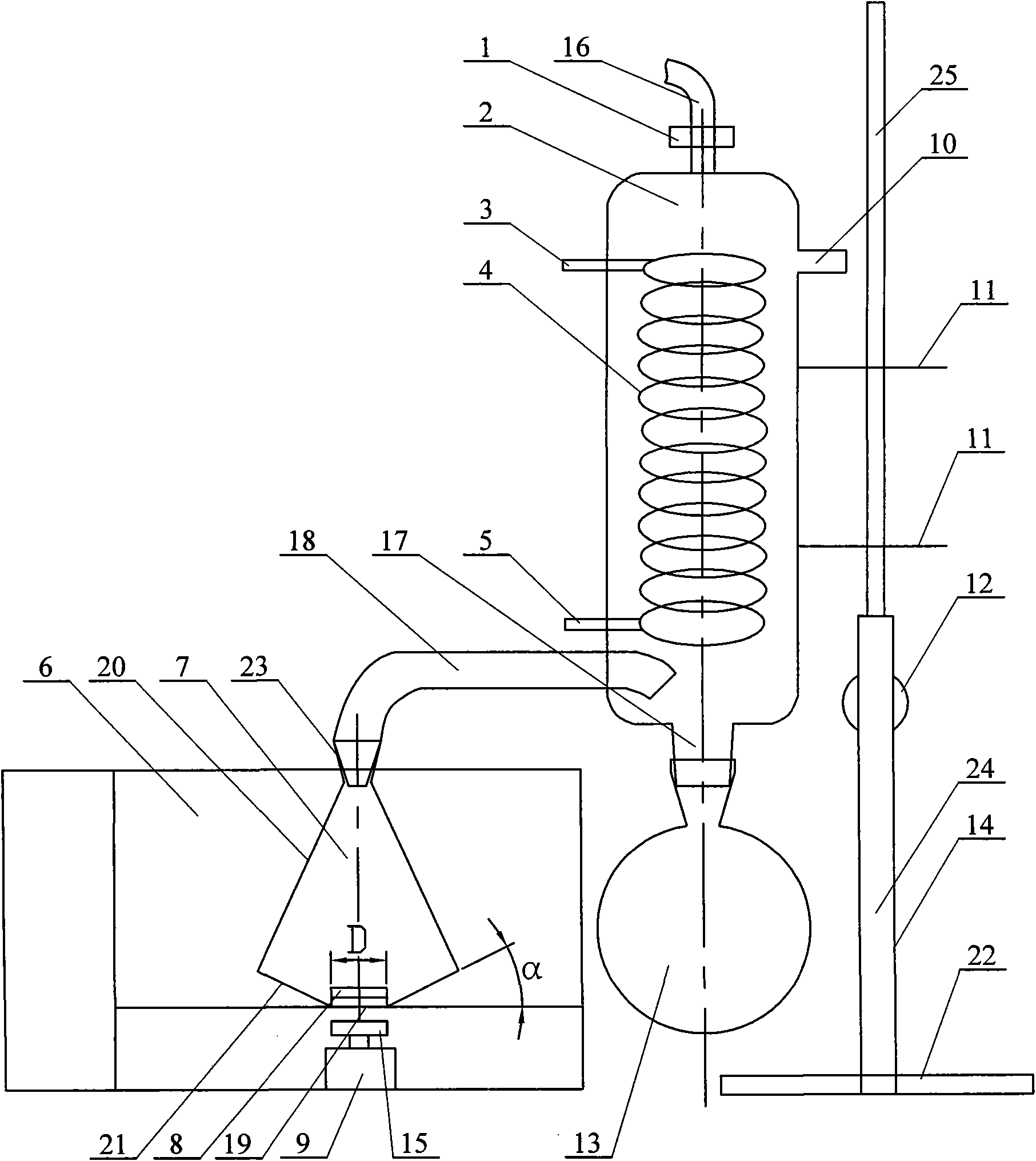

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, the concentrator of this embodiment is made up of magnetic stirring water bath heating device, vacuum condensing device, solvent recovery bottle 13, concentration bottle 7, lifting support 14, two fixing clips 11 and connecting pipe 18; The water bath heating device is composed of a constant temperature water bath pot 6, a magnetic rod 8 with a polytetrafluoroethylene jacket, a long magnet 15 and a motor 9, and the vacuum condensing device is composed of a pressure reducing valve 1, a vacuum chamber 2 and a condensate coil 4 The vacuum chamber 2 is fixedly connected with the lifting bracket 14 by two fixing clips 11, and the condensed water coil 4 is housed in the vacuum chamber 2, one end of the condensed water outlet 3 of the condensed water coil 4 and the condensed water inlet 5 One end is respectively exposed outside through the side wall of the vacuum chamber 2, and the condensed water out...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the bottleneck 23 of the concentration bottle 7 described in this embodiment is gradually reduced in diameter from top to bottom, and the shape of the bottle body of the concentration bottle 7 is gradually reduced by the upper circular platform body 20 and the diameter of the diameter gradually increasing from top to bottom. The lower round platform body 21 is formed, and the diameter of the concentrated bottle bottom 19 is 2cm~4cm, and the angle α between the side wall of the lower round platform body 21 of the concentrated bottle 7 and the horizontal plane is 14°~16°. Such setting can increase the interface area between the gas and liquid phases and speed up the volatilization rate of the solvent. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the diameter of the concentrated bottle bottom 19 described in this embodiment is 3cm, and the included angle α between the side wall of the lower circular table body 21 of the concentrated bottle 7 and the horizontal plane is 15°. Such setting can increase the interface area between the gas and liquid phases and speed up the volatilization rate of the solvent. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com