Method for detecting residual quantity of sodium nitrophenol in aquatic product

A technology of sodium nitrophenolate and sodium o-nitrophenolate, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the problems of low accuracy, cumbersome operation process, cumbersome operation steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

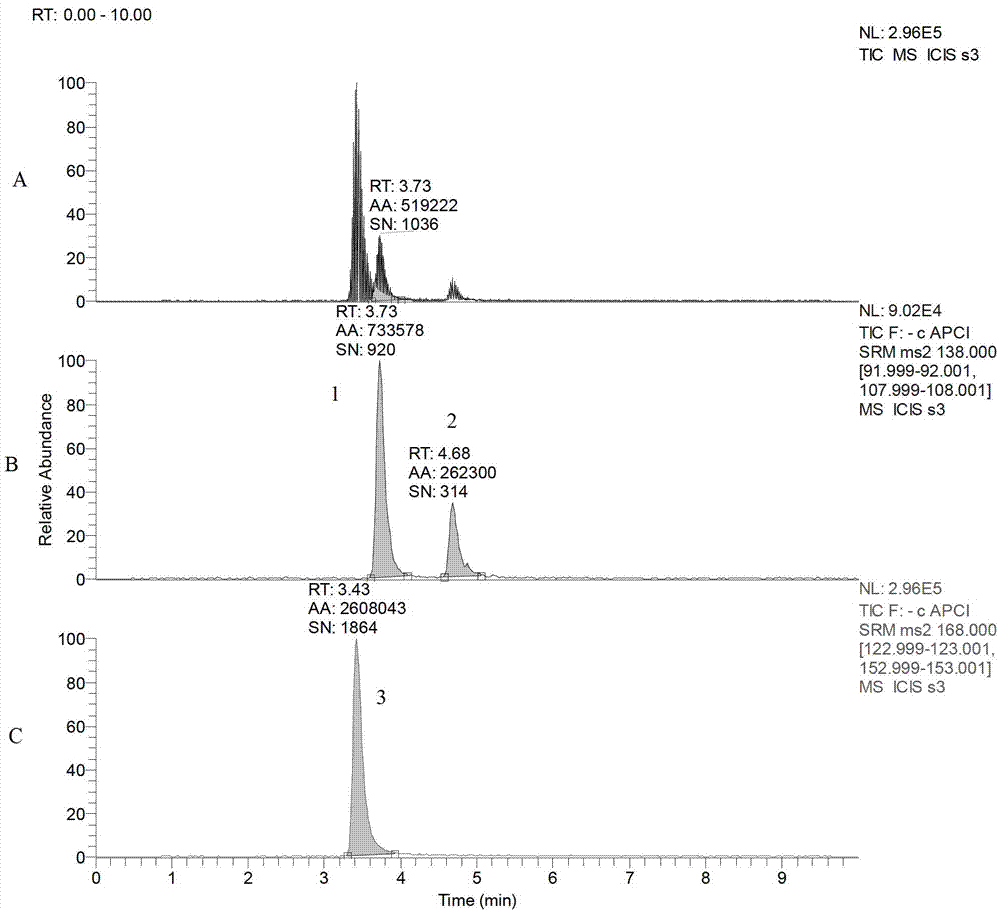

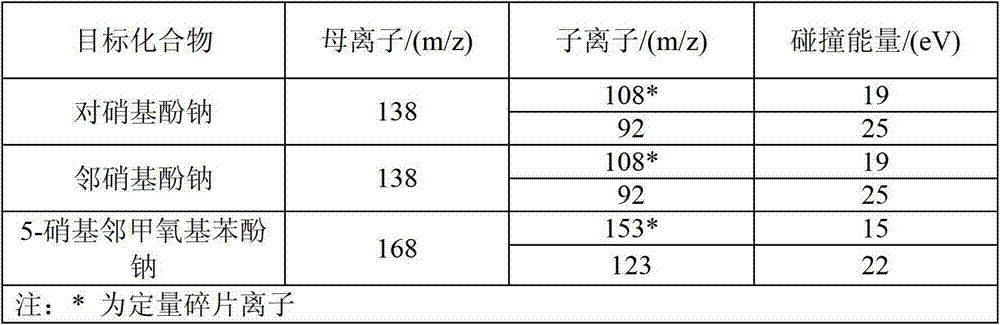

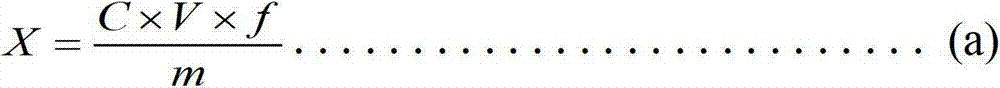

[0068] The mensuration of sodium nitrophenolate residual amount in the eel of embodiment 1

[0069] 1. Instruments and equipment used in this embodiment: LC / APCI-MS / MS liquid chromatography-tandem mass spectrometer

[0070] (1) HPLC part (Thermo Fisher company, model Surveyor), using MS high-pressure liquid phase pump, equipped with automatic sampler, column thermostat, using CAPCELL PAK C 18 Reverse-phase chromatographic column, 150mm×2.1mm, 5μm.

[0071] (2) TSQ Quantum Access mass spectrometer (Thermo Fisher): equipped with APCI ion source, triple quadrupole, collision cell, vacuum system, and gas path control system;

[0072] (3) Ultrasonic cleaner (Kunshan Ultrasonic Instrument Co., Ltd., model KQ-600DE);

[0073] (4) High-speed refrigerated centrifuge: 10000r / min (HITACHI, model CR22G);

[0074] (5) High-speed centrifuge: 4000r / min (Thermo Fisher);

[0075] (6) Vortex mixer (Talboys);

[0076] (7) Rotary evaporator (German Heidoplh company, model Laborota4000);

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com