Sludge concentration dehydration method

A sludge concentration and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of inconvenient loading and unloading and transportation of sludge, large heat consumption, long concentration time, etc. , to achieve the effect of being conducive to continuous operation, reducing the processing load and shortening the concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

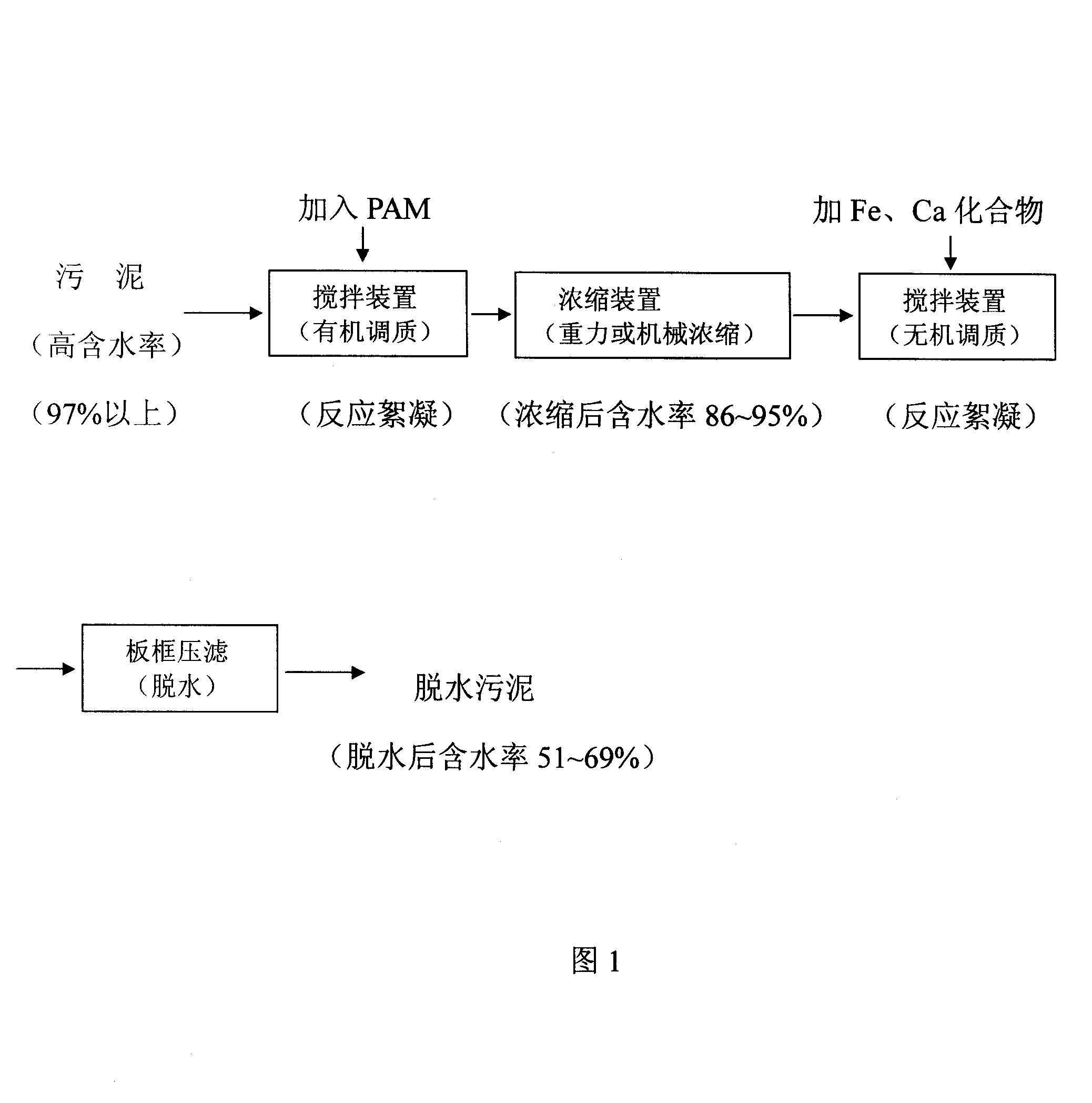

Image

Examples

Embodiment 1

[0023] The remaining sludge with a moisture content of 99.5% in the secondary sedimentation tank of the urban domestic sewage treatment plant is transported to the mixing tank, and polyacrylamide (PAM) is added to fully stir and mix, so that the polyacrylamide (PAM) and the sludge can fully react and flocculate. To realize the first conditioning of sludge, the dosage is 0.12% of the mass of dry sludge. Then transport the conditioned sludge to the sludge thickening tank, let it settle under the action of gravity, and carry out rapid concentration. The concentration time is 60 minutes, and the water separated from the sludge forms a supernatant, which is Excluded from pool. The thickened sludge is pumped out at the bottom of the thickening tank and sent to the next process. The water content of the thickened sludge is 93%.

[0024] Pump the concentrated sludge to the stirring tank for reconditioning, first add Fe compound, the dosage is 1.9%, and then add Ca compound, the dosag...

Embodiment 2

[0026] The remaining sludge with a moisture content of 99.7% in the secondary sedimentation tank of the urban domestic sewage treatment plant is transported to the mixing tank, and polyacrylamide (PAM) is added to fully stir and mix, so that the polyacrylamide (PAM) and the sludge can fully react and flocculate. To realize the first conditioning and tempering of sludge, the dosage is 0.15% of the dry sludge mass. Then the conditioned sludge is transported to the sludge concentration tank to make it settle under the action of gravity for rapid concentration. The concentration time is 120 minutes, and the water separated from the sludge forms a supernatant, which is Excluded from pool. The concentrated sludge is pumped out at the bottom of the thickening tank and sent to the next process. The water content of the concentrated sludge is 90%.

[0027] Pump the concentrated sludge to the stirring tank for reconditioning, first add Fe compound, the dosage is 2.28%, and then add Ca ...

Embodiment 3

[0029] The remaining sludge with a moisture content of 99.3% in the secondary sedimentation tank of the urban domestic sewage treatment plant is transported to the mixing tank, and polyacrylamide (PAM) is added to fully stir and mix, so that the polyacrylamide (PAM) and the sludge can fully react and flocculate. To realize the first conditioning of sludge, the dosage is 0.16% of the mass of dry sludge. Then the conditioned sludge is transported to the sludge concentration tank to make it settle under the action of gravity for rapid concentration. The concentration time is 120 minutes, and the water separated from the sludge forms a supernatant, which is Excluded from pool. The concentrated sludge is pumped out at the bottom of the thickening tank and sent to the next process. The water content of the concentrated sludge is 90.7%.

[0030] Pump the concentrated sludge to the stirring tank for reconditioning, first add Fe compound, the dosage is 2.09%, and then add Ca compound,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com