An electric field enhanced fast membrane concentration method and device

A membrane concentration and rapid technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., to achieve rapid concentration, simple process and operation, and improve concentration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

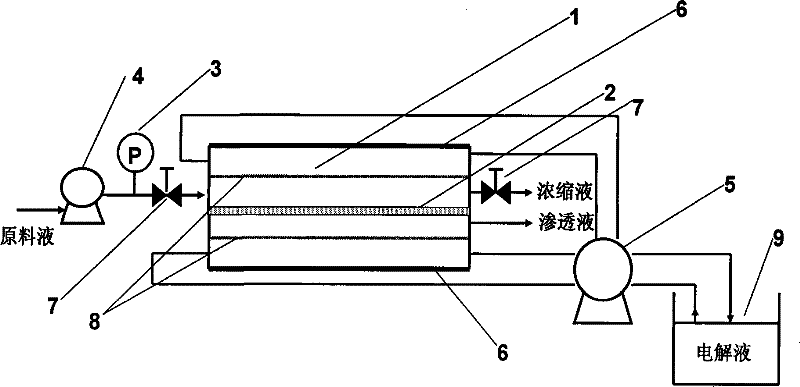

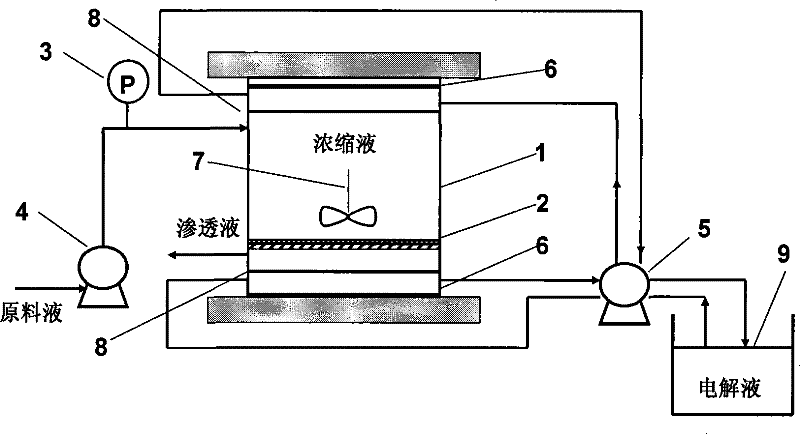

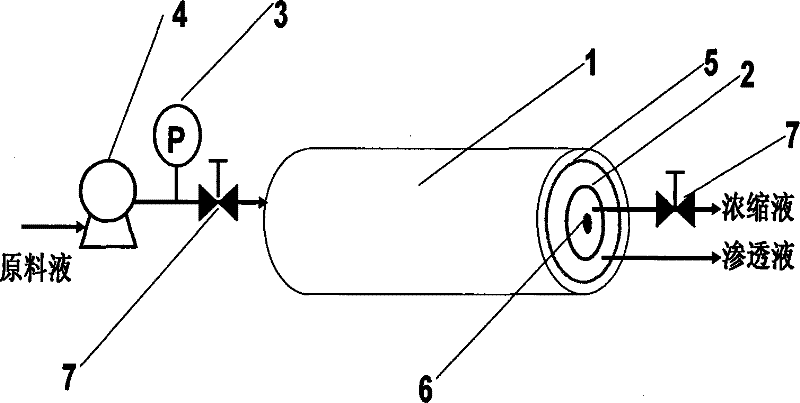

[0038] use figure 1 The fast membrane concentration device under the electric field conditions shown includes: flat membrane module 1, filter membrane 2, pressure sensor 3, feed pump 4, electrolyte circulation pump 5, electrode 6, flow regulating valve 7, isolation membrane 8 ;Electrolyte storage tank 9

[0039] In the flat membrane module 1 (the effective membrane area is 45cm 2 ) is equipped with a flat filter membrane 2 in the middle, and the filter membrane is selected as a PS polysulfone ultrafiltration membrane (Alfa Laval Company of Denmark) with a molecular weight cut-off (MWCO) of 100kDa. Titanium (ruthenium-plated) electrode 6; two isolation membranes 8 are sandwiched between the electrode and the feed solution, the cut-off molecular weight is 3500Da, the space between the isolation membrane 8 and the electrode 6 is the electrolyte circulation chamber, and the electrolyte circulates in the electrolyte Under the action of the pump 5, it circulates between the upper ...

Embodiment 2

[0043] The same apparatus and method as in Example 1 were used.

[0044] A solution of bovine serum albumin (BSA) (Mb=68kDa, purity greater than 98%) with a fixed volume (400mL) and a concentration of 1.0g / L is delivered to the above-mentioned membrane module through a feed pump, and the transmembrane pressure of the filter membrane is 0.04MPa , the cross-flow velocity of the feed liquid flowing through the membrane surface is 0.03m / s, and the pH value of the feed liquid is adjusted to about 8; the electrode is connected to an external DC power supply, and the electric field strength is adjusted to 30V / cm; the feed liquid cross-flows through the membrane The components are then returned to the feeding system for recycling; the permeate permeated through the membrane is continuously discharged and collected from the permeate outlet below the filter membrane. When the accumulated permeate reaches 200mL, the operation is stopped, the concentration time is recorded, and respectivel...

Embodiment 3

[0047] Using the same device and method as in Example 1, the filter membrane used is a 30 kDa PES polysulfone ultrafiltration membrane.

[0048] The lysozyme (Mb=14kD, purity greater than 98%) solution with a fixed volume of 400mL and a concentration of 1.0g / L is delivered to the above-mentioned membrane module through a feed pump, the transmembrane pressure of the filter membrane is 0.04MPa, and the feed liquid flows through The cross-flow velocity of the membrane surface is 0.03m / s, and the pH value of the feed liquid is adjusted to about 8; the electrode is connected to an external DC power supply, and the electric field strength is adjusted to 50V / cm; the feed liquid cross-flow passes through the membrane module and returns to the inlet In the material system, it is recycled; the permeate that permeates the membrane is continuously discharged and collected from the permeate outlet below the filter membrane. When the permeate accumulation reaches 200mL, stop the operation, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com