Sectional corn dipping method

A segmented, corn technology, applied in the field of dipping corn, can solve the problems of high cost and long time, and achieve the effect of reducing heat loss and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

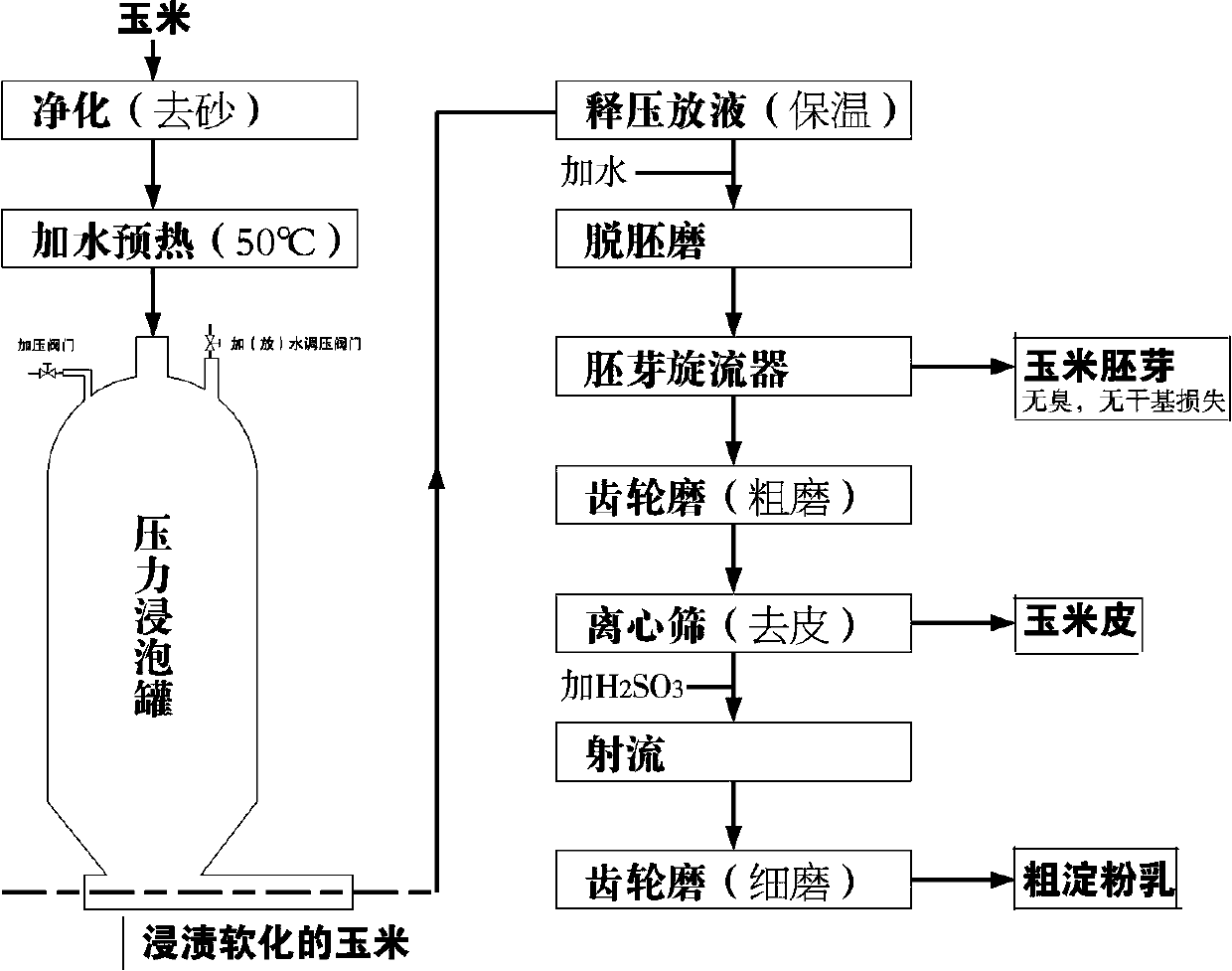

[0045] like figure 1 Shown, the present invention comprises the steps:

[0046] Purification: the corn is cleaned to remove impurities;

[0047] Preheating: In the preheating tank, the above-mentioned purified corn and water are mixed and preheated in the ratio of corn:water=1:1.5 in parts by weight. Preheat the flowing water at 50°C-60°C, and the hot water circulation preheating time is 15 minutes to 30 minutes;

[0048] Dipping I: Put the above-mentioned preheated corn into the pressure tank with a PW-type sludge pump, and seal all the valves, use a high-pressure pump to pressurize to 1.5MP, keep the temperature at 50°C, and use a high-pressure pump to supplement the pressure every half an hour , soaked for 2 hours; make the mass percentage of the water content of the corn reach 40% to 45%;

[0049] Release the pressure and release the liquid: Release the pressure of the above impregnated materials, and put the corn and soaking water into the buffer tank at the same time,...

Embodiment 2

[0060] In the preheating step, the ratio of corn to water in parts by weight is corn:water=1:1. The hot water circulation preheating method can complete the preheating process within 15 minutes.

[0061] In the impregnation II step, dry basis and H 2 The weight and number ratio of SO3 solution is, dry basis: H 2 SO 3 Solution=1:2. Other steps are the same as in Example 1.

Embodiment 3

[0063] In the preheating step, the weight and number ratio of corn to water is corn:water=1:3. Static preheating is adopted, and the preheating process is completed within 15 minutes. Other steps are with embodiment 1

[0064] The working principle of the present invention is as follows:

[0065] The technical key point that the present invention is mainly different from the wet-dipping corn is to divide the original "one-time soaking" into "two stages", that is, "soaking I" and "soaking II" mentioned below, and moving the second stage to Before the starch separation process, the process time of the "soaking II" stage can be paralleled with the other process time courses.

[0066] The soaking I step of the present invention, its purpose is different from the existing soaking method, is only to macerate the corn and is easy to break, not for the purpose of decomposing corn gluten protein. Therefore, the whole process is that the water moves to the inside of the corn kernels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com