Microchannel chip and method for gas-liquid phase separation using same

a microchannel chip and gas liquid phase separation technology, applied in the direction of photometry, optical radiation measurement, biological material analysis, etc., can solve the problems of deteriorating accuracy of ultra-fine process patterning, increasing the defect rate, and inability to prompt action, etc., to achieve good reproducibility and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

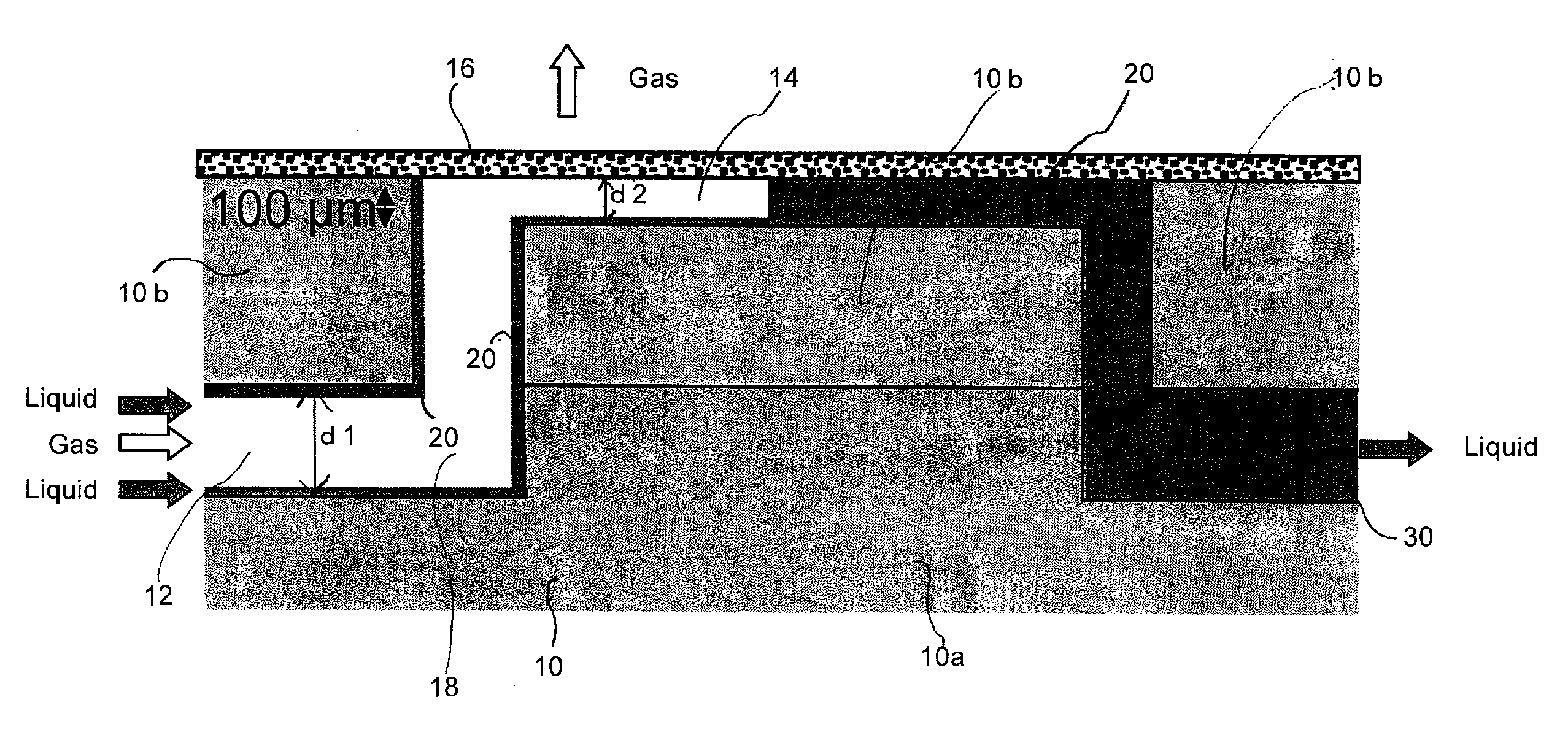

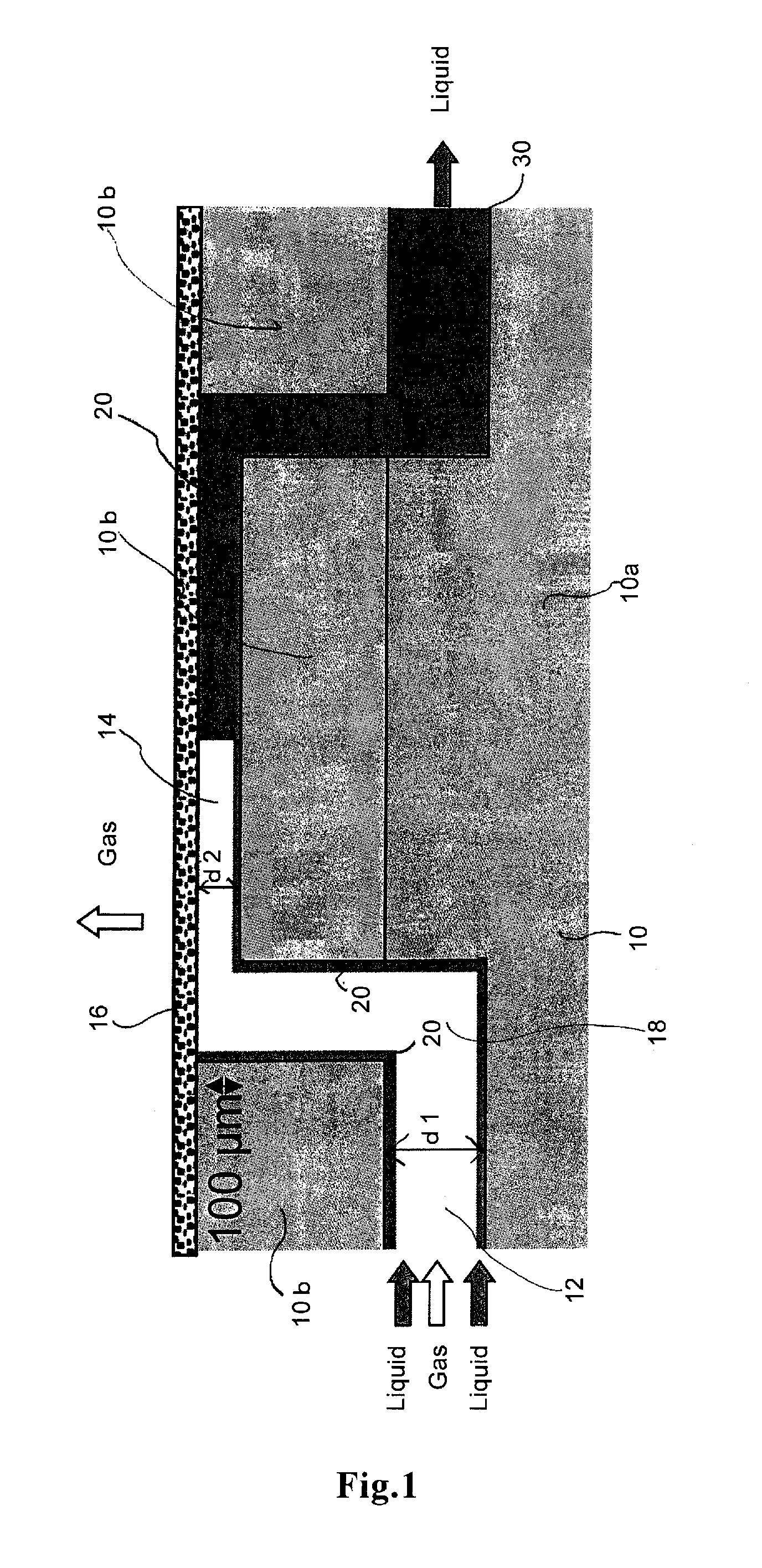

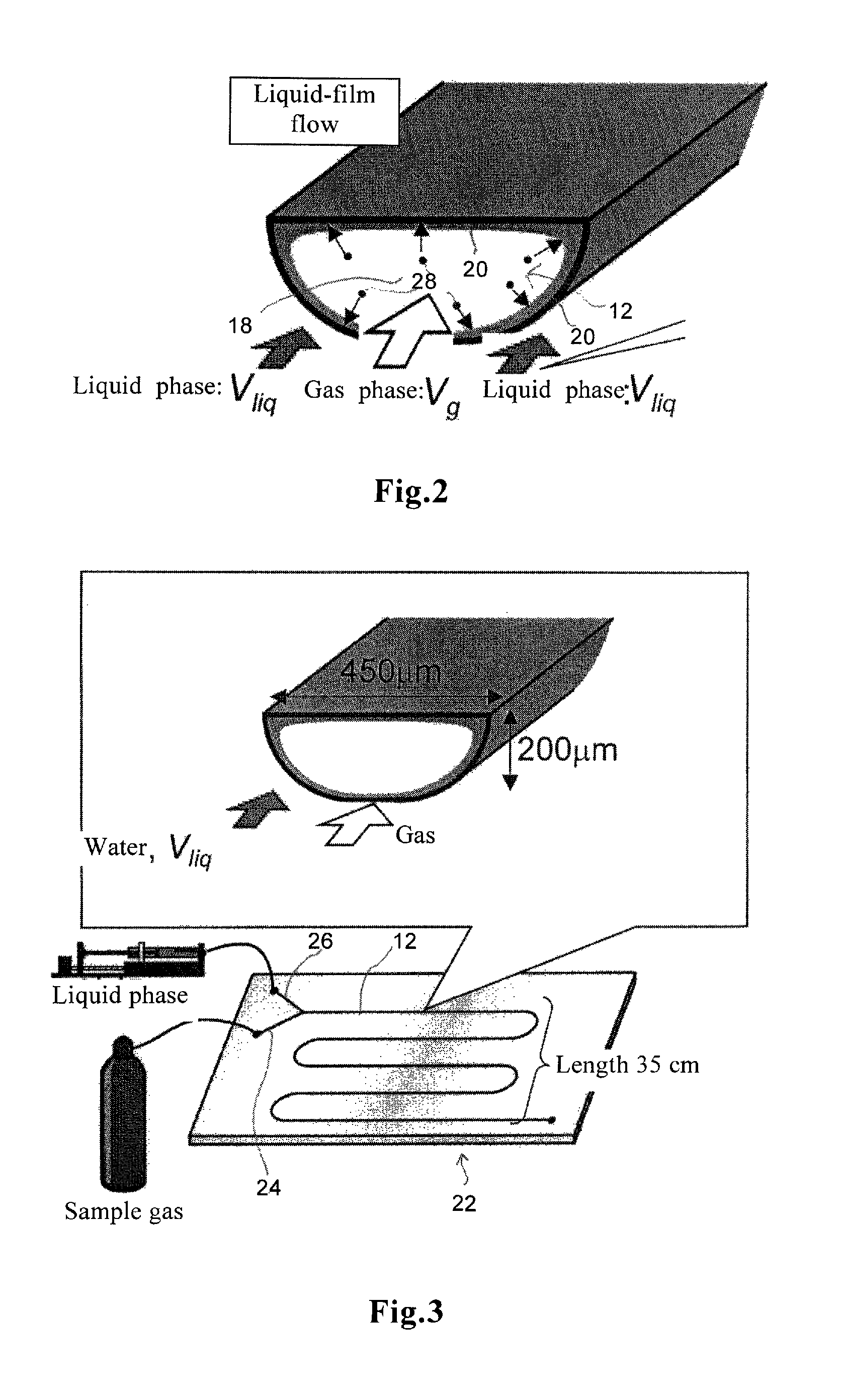

[0062]A microchannel chip having the gas-liquid phase separation microchannel shown in FIG. 1 was prepared. The schematic plan view thereof is shown in FIG. 4. To the test substance-measuring microchannel 30, an oxidizing solution introduction microchannel 34 and a coloring solution introduction microchannel 36 were connected. In the microchannel chip shown in FIG. 4, after allowing a collection solution to which ammonia gas was dissolved to pass through a gas-liquid phase separation part, the collection solution is once led to a tube arranged outside of the chip (indicated by a solid arrow in FIG. 4). The collection solution is then re-introduced to the channel inside the chip and combined with a coloring solution and an oxidizing solution and these are allowed to react in a further downstream of the microchannel. It is noted here that FIG. 4 shows a substrate on which microchannels are formed and that the microchannel of the part enclosed in a rectangle and indicated as “gas-liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com