Phase change thermal storage tester

A phase change heat storage and tester technology, which is applied in the field of testing equipment and heat storage performance testing, can solve the problems of restricting the development of the building phase change material industry and the lack of standards and specifications for building phase change materials enterprises, and achieves expanded use. Scope, the effect of simple operation interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

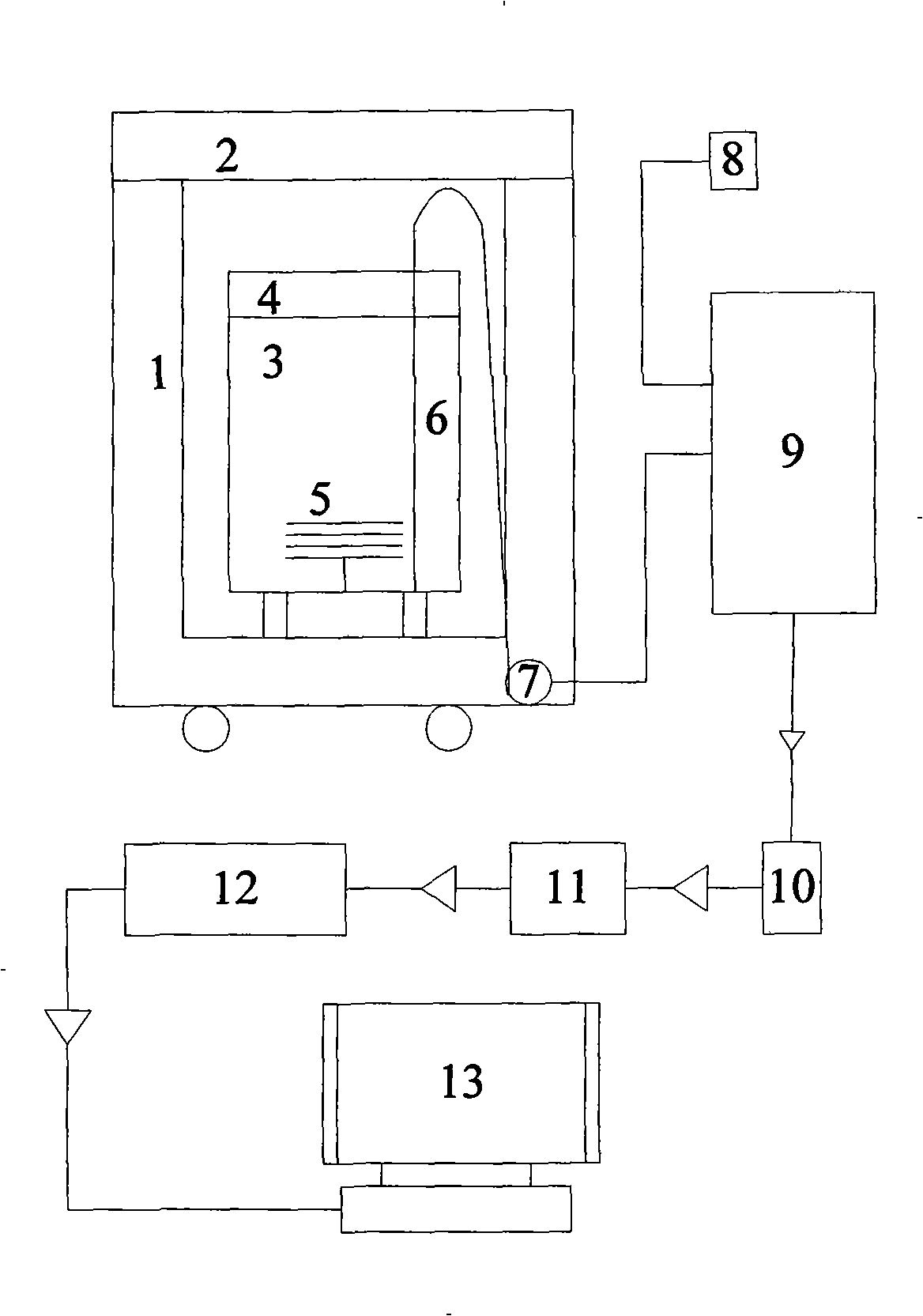

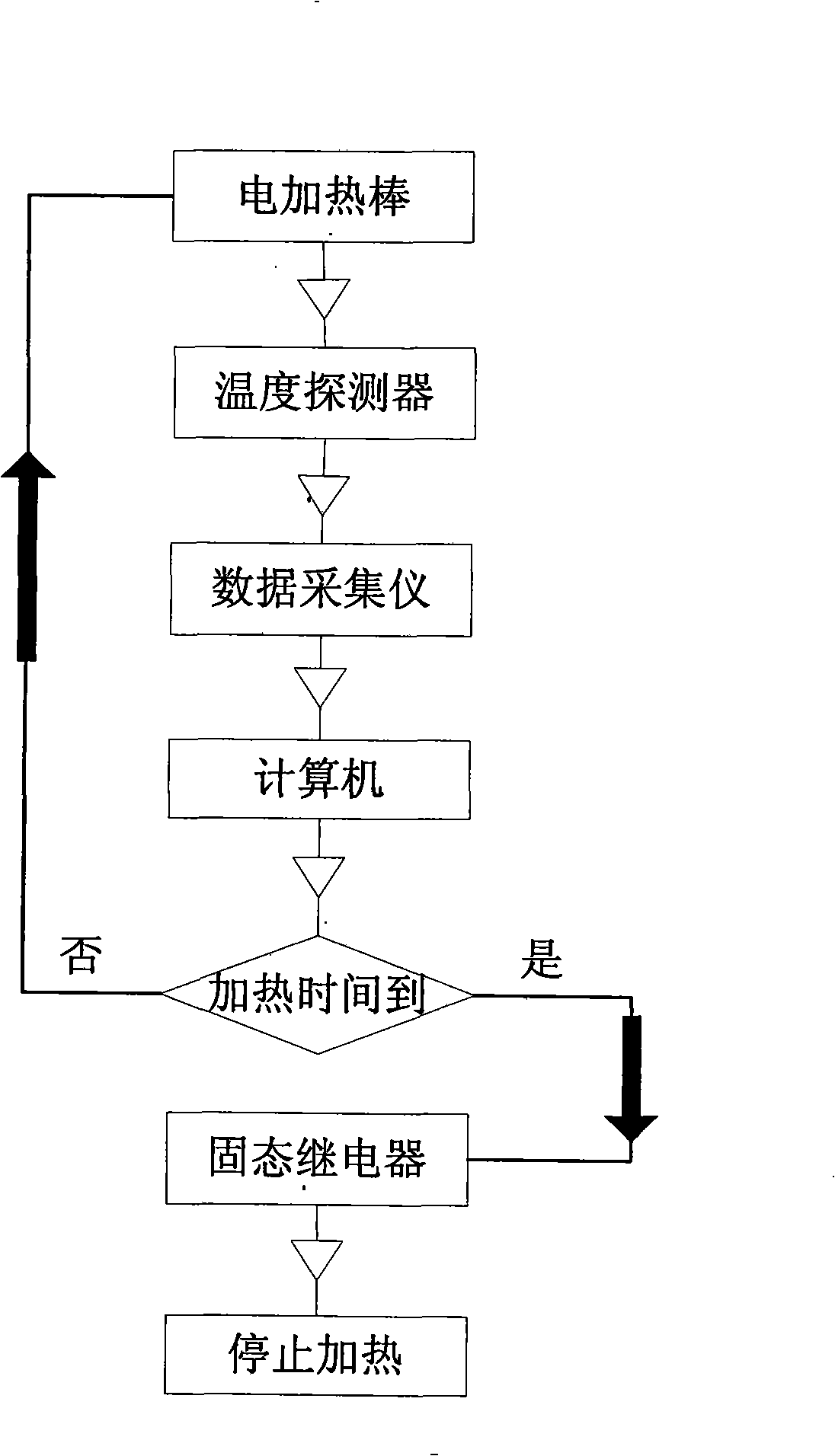

[0054] First add water in the inner heating barrel 3, when the water reaches the mark in the inner heating barrel, stop adding water; then cover the inner heating barrel cover 4, and then cover the outer heat preservation barrel cover 2. The water bath section is ready for controlled heating. Then turn on 13 computers, and supply power to the voltage stabilizer 9 and the data acquisition instrument 12 of the heating barrel 3, and complete the heating setting on the 13 computers simultaneously. This mainly includes setting the phase change temperature of the phase change material, setting the heating time of the heat leakage test and the heat capacity test, and setting the heat leakage power of the heat leakage test. After these three settings are completed, click the start button on the interface to start heating. The temperature detector 6 collects data every 5 seconds, and converts it into a temperature value, which is displayed on the interface of the computer 13, and simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com