Hot stamping mould with temperature measuring system

A temperature measuring thermocouple and mold technology, applied in the field of hot stamping, can solve problems such as difficult judgment and evaluation, low completion rate of tissue transformation, and difficulty in monitoring and measuring the temperature change rate of molds and sheets, avoiding the problems of Long-term and high-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

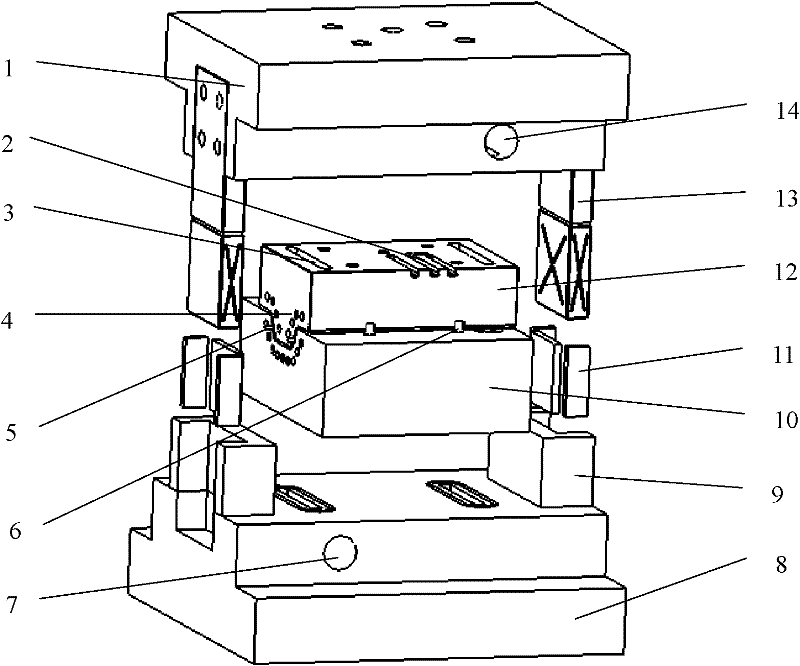

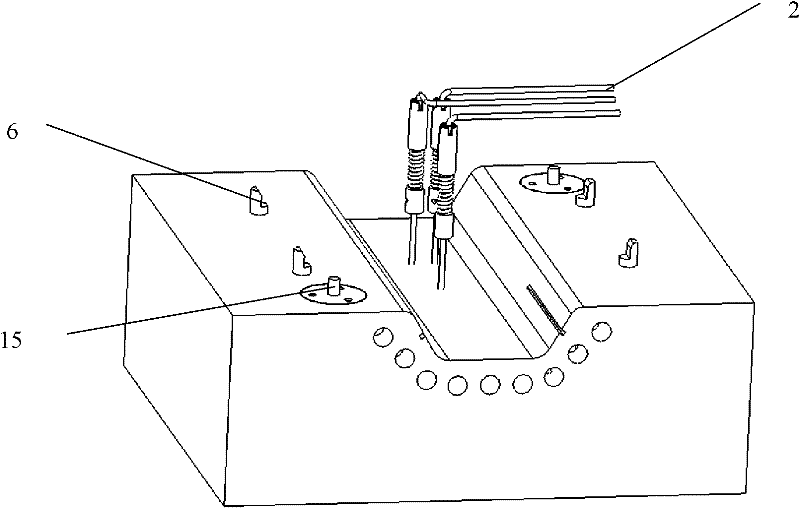

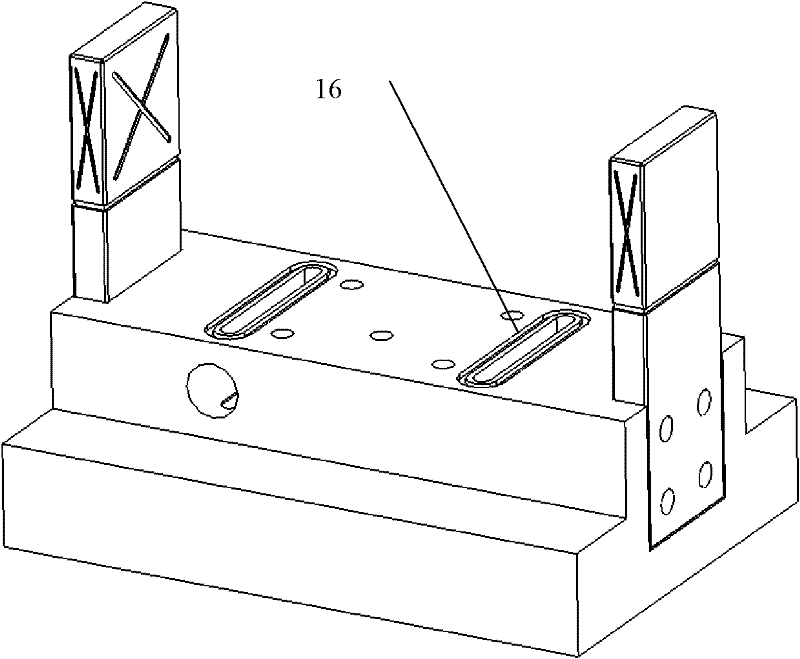

[0030] Now refer to the attached Figure 1-6 , the present invention is further described in conjunction with specific embodiments:

[0031] The hot stamping die with self-contained temperature measuring system according to the present invention, taking U-shaped parts as an example, the die includes a die mounting plate 8 and a die 10, a punch mounting plate 1 and a punch 12, a punch 12 and a die The cooling pipes 4 are staggeredly laid in the mold 10, and the ends of the cooling pipes 4 are sealed with hexagon socket plugs. The cooling pipes 4 are connected to the distribution tank, one end of the distribution tank is connected to the cooling pipe, and the other end is connected to the water inlet. Sealed to form a smooth cooling circuit.

[0032] The punch 12 is fixed on the punch mounting plate 1, one end of the punch mounting plate 1 is provided with a punch water inlet 14, and the other end is provided with a punch water outlet 18 in the opposite direction, and the punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com