Low-formaldehyde chipboard and preparation method thereof

A particleboard and low-formaldehyde technology, applied in the field of low-formaldehyde particleboard and its preparation, can solve the problems of large formaldehyde emission from all-urea-formaldehyde-adhesive particleboard, long production cycle of all-soybean gum particleboard, reduction of formaldehyde emission from particleboard, etc., and shortens hot pressing. Time, ease of industrial production, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

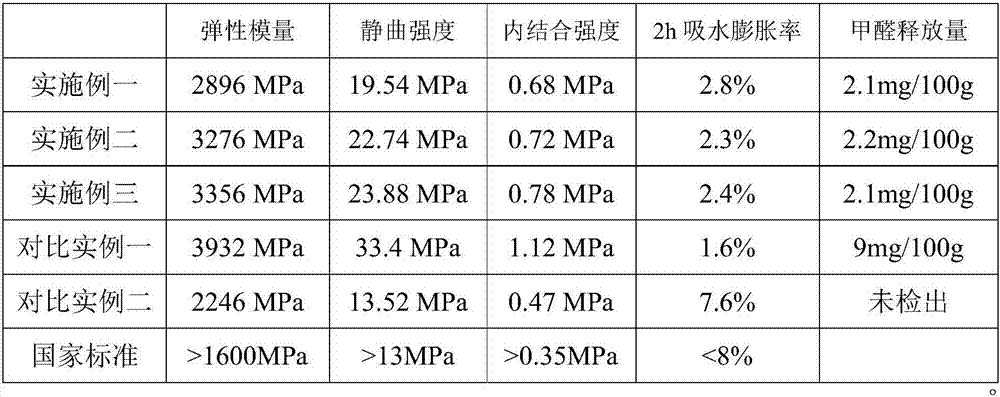

Examples

Embodiment 1

[0029] Formaldehyde-free soybean gum raw material proportioning by weight is as follows:

[0030] Low-temperature defatted soybean powder (commercially available): 30 parts

[0031] Crosslinking agent (silane coupling agent KH570): 4.8 parts

[0032] Acid-base regulator (sodium hydroxide): 0.2 parts

[0033] Tackifier (15% concentration of polyvinyl alcohol solution): 20 parts

[0034] Water: 45 parts.

[0035] Set the density of the particleboard to 700kg / m 3 , before sizing, use low-temperature defatted soybean powder as a powder component, mix crosslinking agent, acid-base regulator, tackifier, and water evenly, and use formaldehyde-free soybean gum and surface shavings according to the weight ratio The ratio is 28:100, for sizing, the powder component is added to the mixing bin and mixed evenly with the shavings by means of spiral weighing and metering, and at the same time, the liquid component is sprayed onto the surface of the shavings in the mixing bin. The urea-f...

Embodiment 2

[0038] The ratio of formaldehyde-free soybean gum raw materials by weight is as follows:

[0039] Low-temperature defatted soybean flour: 28 servings

[0040] Crosslinking agent (epoxy resin): 5 parts

[0041] Acid-base regulator (oxalic acid): 0.3 parts

[0042] Tackifier (rosin emulsion with 30% solid content): 23.7 parts

[0043] Water: 43 parts.

[0044] Set the density of the particleboard to 710kg / m 3 , before sizing, use low-temperature defatted soybean powder as a powder component, mix crosslinking agent, acid-base regulator, tackifier, and water evenly, and use formaldehyde-free soybean gum and surface shavings according to the weight ratio The ratio is 30:100, for sizing, the powder component is added into the mixing bin and mixed evenly with the shavings by means of spiral weighing and metering, and at the same time, the liquid component is sprayed onto the surface of the shavings in the mixing bin. The urea glue and the core layer shavings were applied according...

Embodiment 3

[0047] The ratio of formaldehyde-free soybean gum raw materials by weight is as follows:

[0048] Low temperature defatted soybean flour: 25 parts

[0049] Crosslinking agent (epoxy resin): 6 parts

[0050] Acid-base regulator (calcium hydroxide): 0.5 parts

[0051] Tackifier (rosin emulsion with 40% solid content): 30 parts

[0052] Water: 38.5 parts.

[0053] Set the density of the particleboard to 690kg / m3. Before sizing, use low-temperature defatted soybean powder as the powder component, mix the cross-linking agent, acid-base regulator, tackifier, and water evenly, and use it as the liquid component. The aldehyde soybean gum and the surface layer shavings are sizing according to the weight ratio of 30:100. The powder component is added into the mixing bin and mixed with the shavings evenly by means of spiral weighing and metering. At the same time, the liquid component is sprayed into the mixing chamber. Surface of shavings in the silo. The urea glue and the core lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com