Preparation and application of formaldehyde-free veneering adhesive for artificial board

A technology of veneer glue and wood-based panels, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as general water resistance, slabs that cannot be demoulded, and short open time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-2

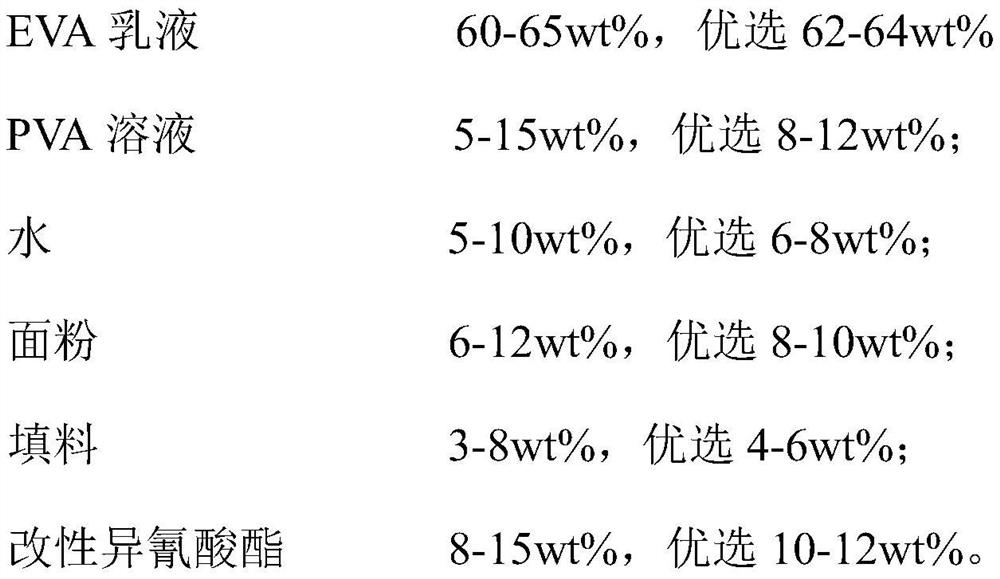

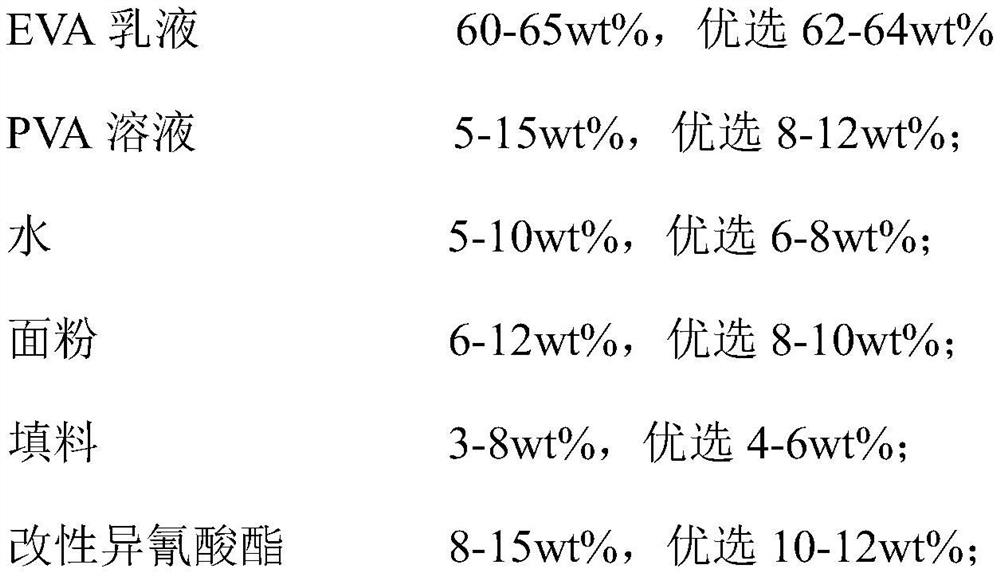

[0044] Raw material mass percent composition (wt%) composition comprises in embodiment and comparative example:

[0045] name Example 1 Example 2 Example 3 Example 4 Example 5 Comparative example 1 Comparative example 2 EVA emulsion 62 60 65 60 60 40 65 PVA solution 8 10 5 5 8 20 5 process water 8 8 5 10 5 10 5 flour 6 6 12 10 9 12 12 filler 4 8 3 5 3 5 3 Modified isocyanate 12 8 10 10 15 13 10

[0046] Preparation of formaldehyde-free veneer adhesive, including:

[0047] 1. Preparation of modified isocyanate:

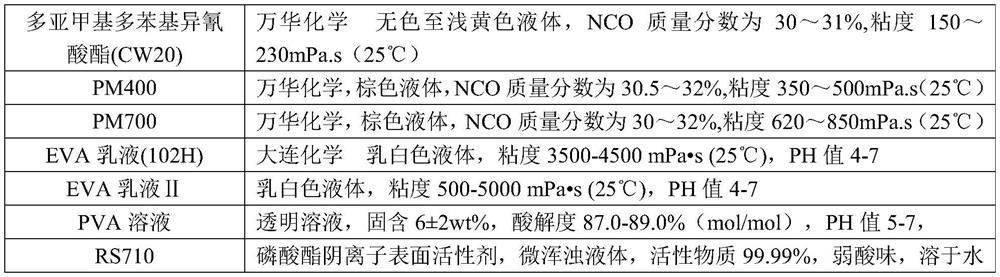

[0048] Pour 300g of isocyanate into a 500ml three-neck flask, slowly heat to 50°C, and add RS710 dropwise into the isocyanate liquid under stirring conditions, stir for about 50min, take it out, and set aside;

[0049] in:

Embodiment 1

[0050] In Example 1, the isocyanate is CW20, the addition amount of RS710 is 30g; the EVA emulsion is 102H; the solid content of the PVA solution is 5%; the filler is calcium carbonate;

Embodiment 2

[0051] In Example 2, the isocyanate is CW30, the addition amount of RS710 is 15g; the EVA emulsion is 102H; the solid content of the PVA solution is 8%; the filler is talcum powder;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com