Substrate placement unit

A substrate and tray technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of rising tray manufacturing costs, widening intervals, increasing tray deformation, etc., to minimize temperature deviation, Effect of preventing temperature deviation and improving tray life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention is not limited or limited by the embodiments. For reference, in this description, the same symbols refer to substantially the same elements, under this rule, the content recorded in other drawings can be cited for description, and it can be omitted. Obvious or repetitive content.

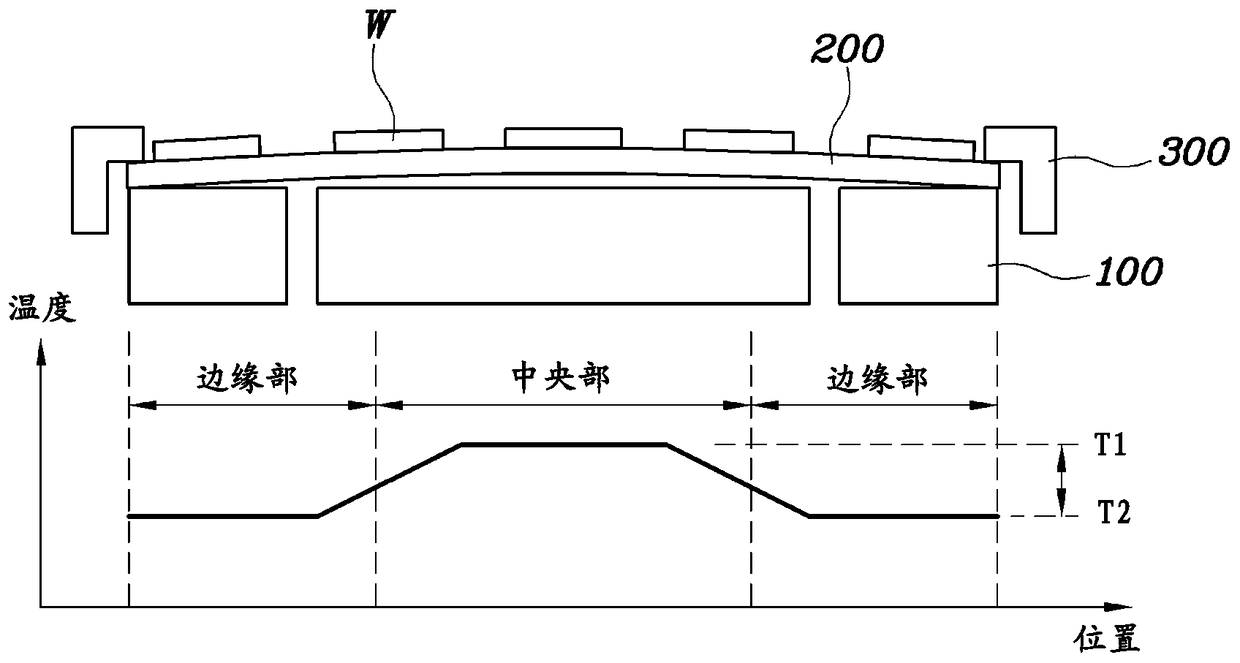

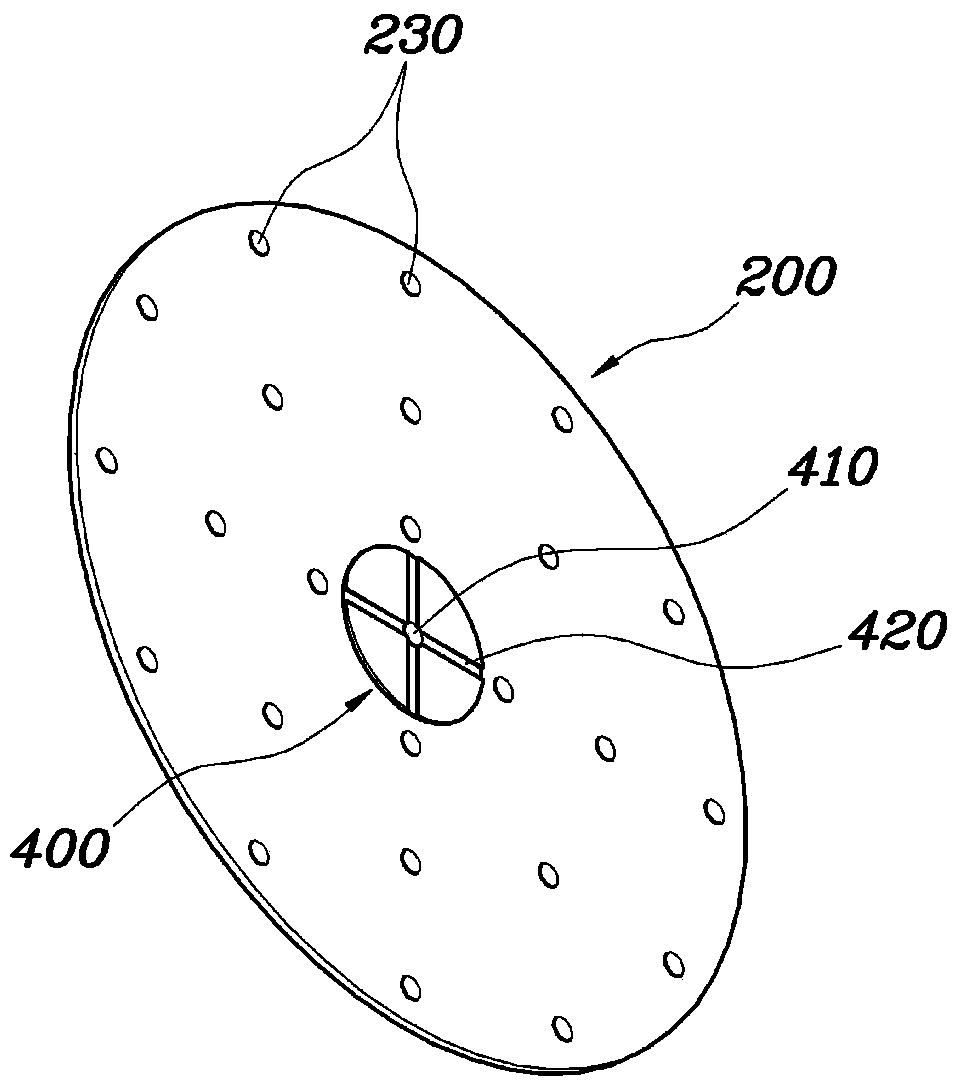

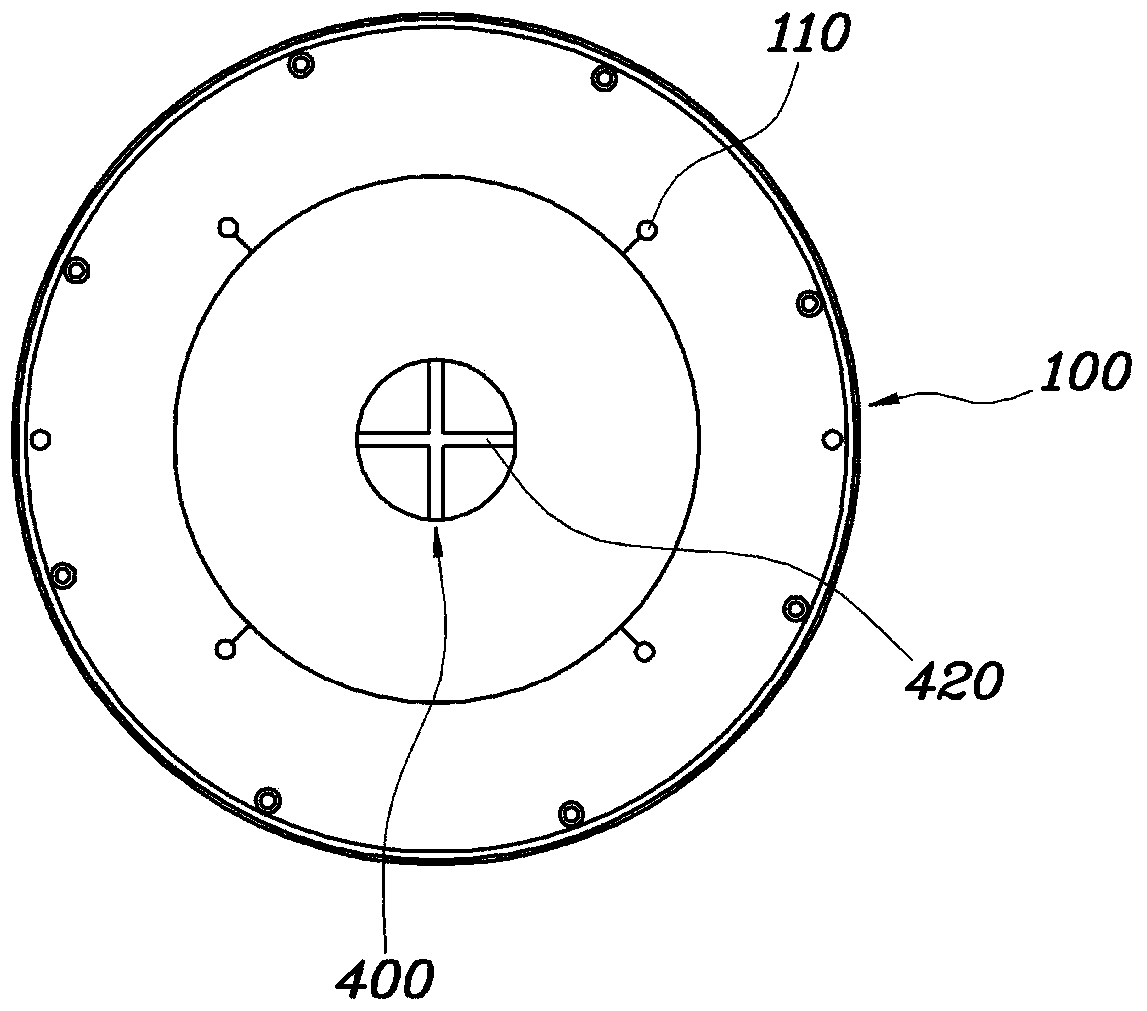

[0054] The substrate placement unit in one embodiment of the present invention includes: a chuck 100, which is arranged inside the cavity of the substrate processing device; a tray 200, which is placed on the upper part of the chuck 100, and a plurality of substrates W are placed on its plane; and clamps 300, which makes the tray 200 and the chuck 100 combined and fixed.

[0055] It is characterized in that when clamps 300 are used to press and fix the edges of the chuck 100 and the tray 200, the center of the tray 200 is deformed to be conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com