Heater assembly and joining head including same

A heater and assembly technology, applied in lighting and heating equipment, heating elements, electric heating devices, etc., can solve the problems of heater thermal deformation, damage, and inability to uniformly cool the entire area of the heater, so as to prevent thermal deformation and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, a bonding head and a heater assembly provided in the bonding head according to an embodiment of the present invention will be described with reference to the accompanying drawings.

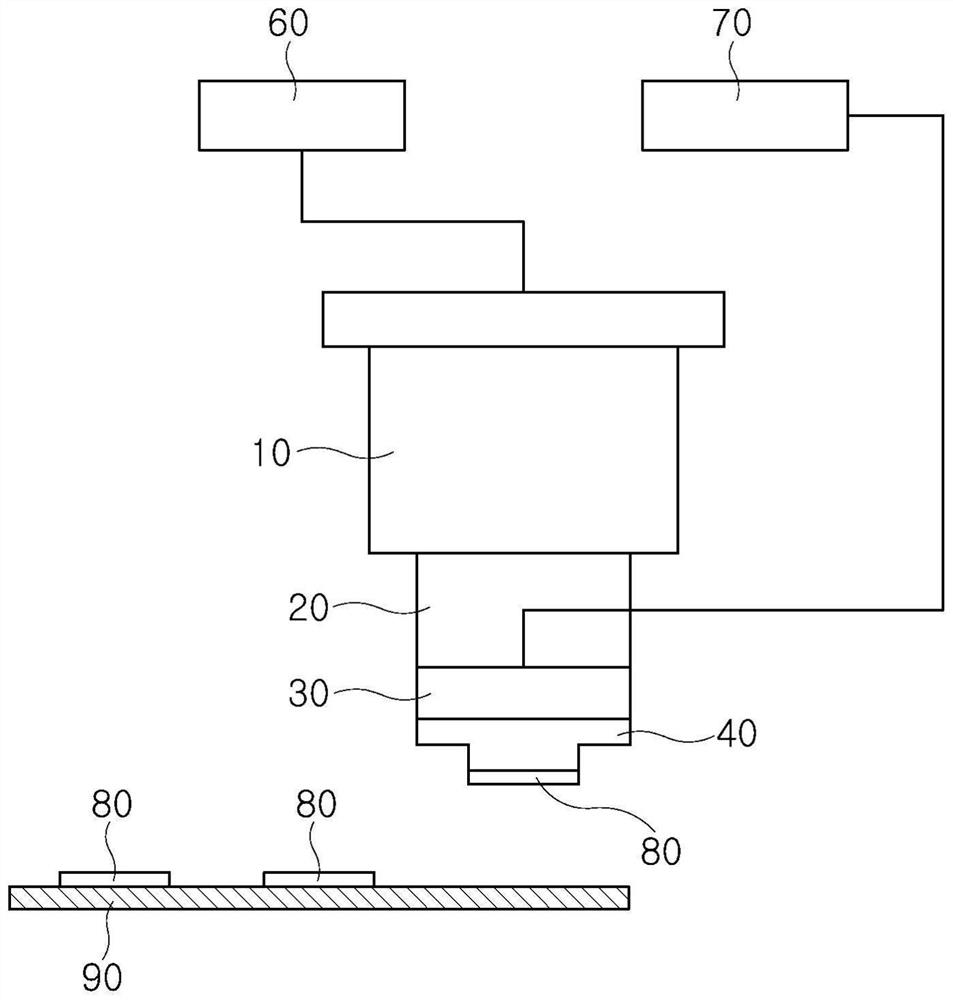

[0055] like figure 1 As shown, the bond head according to the first embodiment of the present invention is configured to pick up dies 80 from a wafer 90 including dies 80 singulated by a dicing process. Bond headers are used to mount die onto substrates such as printed circuit boards, lead frames, etc.

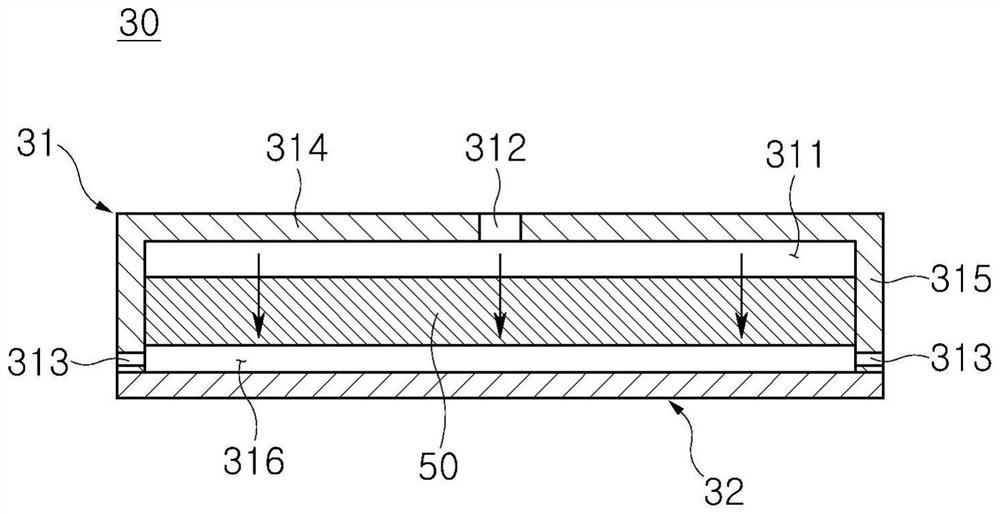

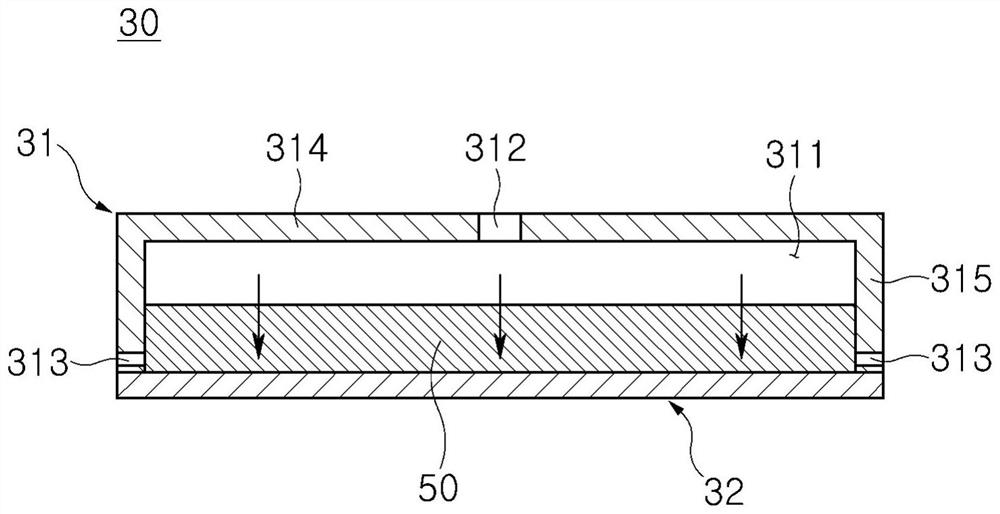

[0056] The bonding head includes a fixing block 10 , a heat insulating block 20 , a heater assembly 30 and a clip body 40 .

[0057] The fixing block 10 may be connected with a driving unit (not shown). The drive unit functions to move the bonding head horizontally and vertically.

[0058] The heat insulating block 20 prevents the heat generated in the heater assembly 30 from being conducted to the fixing block 10 .

[0059] The chuck body 40 may be configured to use negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com