A prepreg automatic laying process parameter determination device

A technique for determining process parameters and devices, which is applied in the field of prepreg automatic laying process parameter determination devices, can solve the problems of many curvature changes, high development costs, and low efficiency, so as to improve test efficiency, reduce research costs, and avoid temperature problems. The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

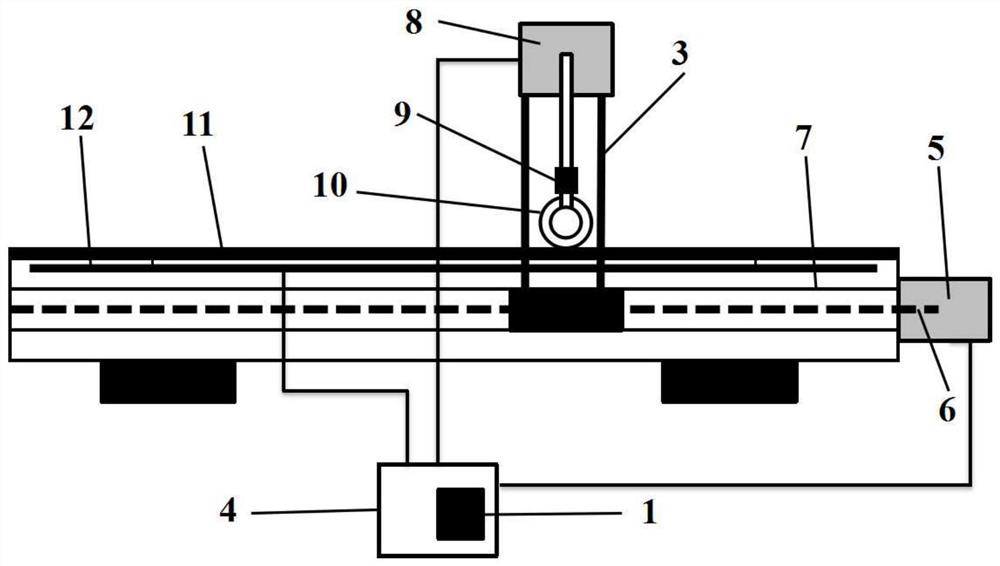

[0037] The invention discloses a prepreg automatic laying process parameter determination device and a test method, which belong to the technical field of composite material automatic forming equipment design and are used for simulation verification of prepreg automatic laying process parameters. The test device includes: a speed control unit, a pressure control unit, a temperature control unit, a control device and a data processing module. The prepreg data processing module (1) provides preset pressure to the prepreg through the flexible pressure roller (10) according to the set servo mechanism (8), sets the working parameters of the stepping motor (5), and sets the heating The constant temperature provided by the device (12) to the worktable (11) and the bonding force and strain force of the prepreg after the set laying process test are due to the optimal bonding force of the specific prepreg for laying and strain force are measurable data, and the best laying process param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com