Ion injectivity optimizing method for photovoltaic infrared detector tellerium-cadmium-mercury materials

An infrared detector and ion implantation technology, which is applied in semiconductor/solid-state device testing/measurement, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of time and energy, high test cost, and incomparability, and achieve Save time and effort, lower test costs, and improve comparability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It is now described in conjunction with the accompanying drawings:

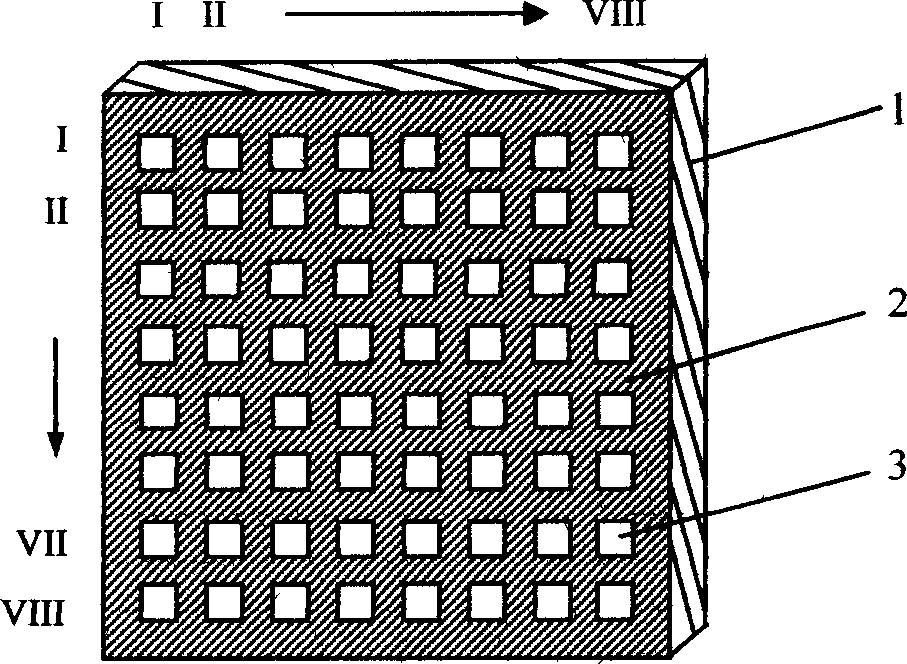

[0020] figure 1 It is the base material under test (MCT) sample, the sample is square, the surface layer of the base material of the sample is peeled off to expose a fresh mercury cadmium telluride layer 1, and then a layer of ZnS is evaporated as a barrier layer 2 for ion implantation, and in On the barrier layer, the implantation regions 3 of rows VIII and columns VIII, rows I-VIII in the horizontal direction and columns I-VIII in the vertical direction are regularly photoetched.

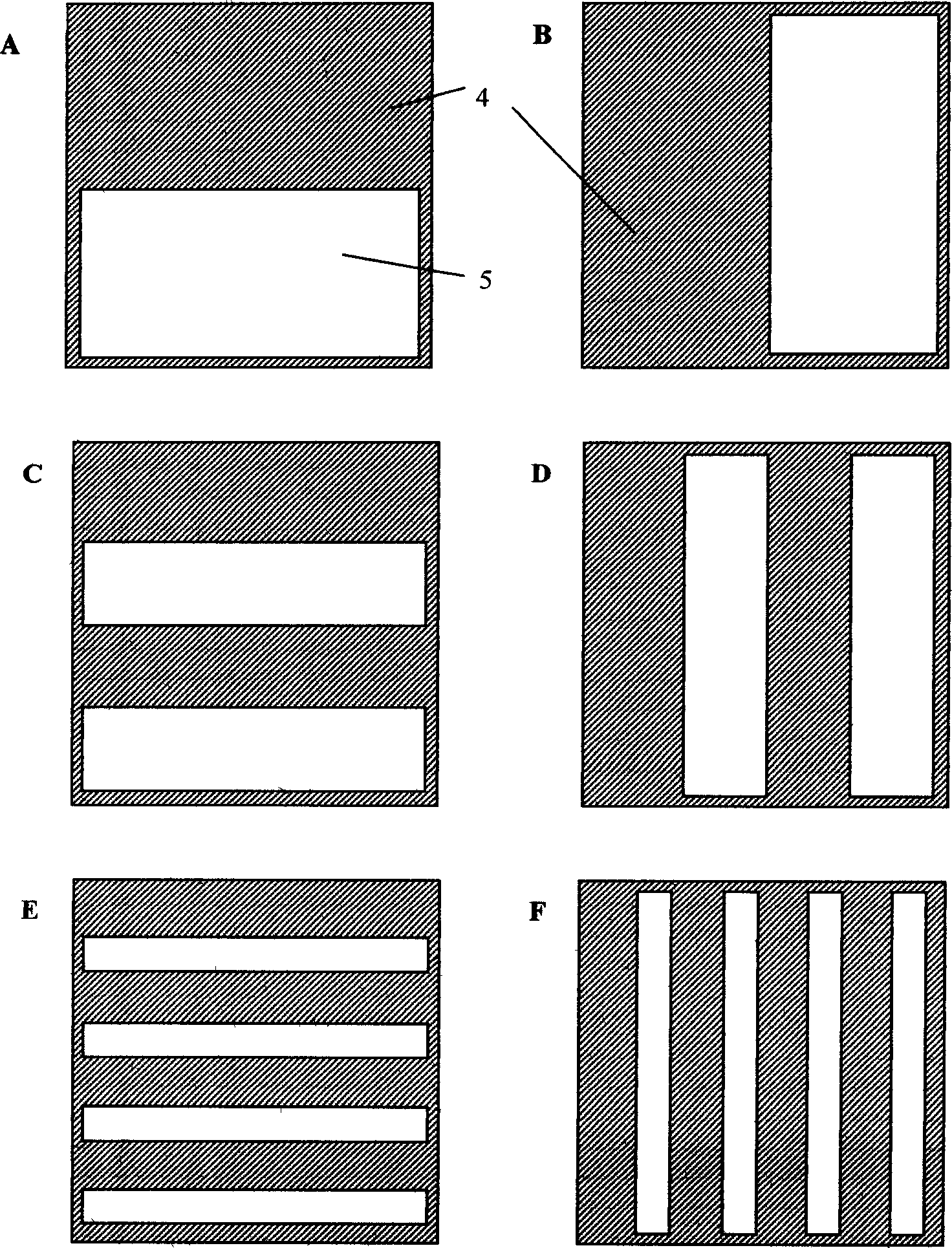

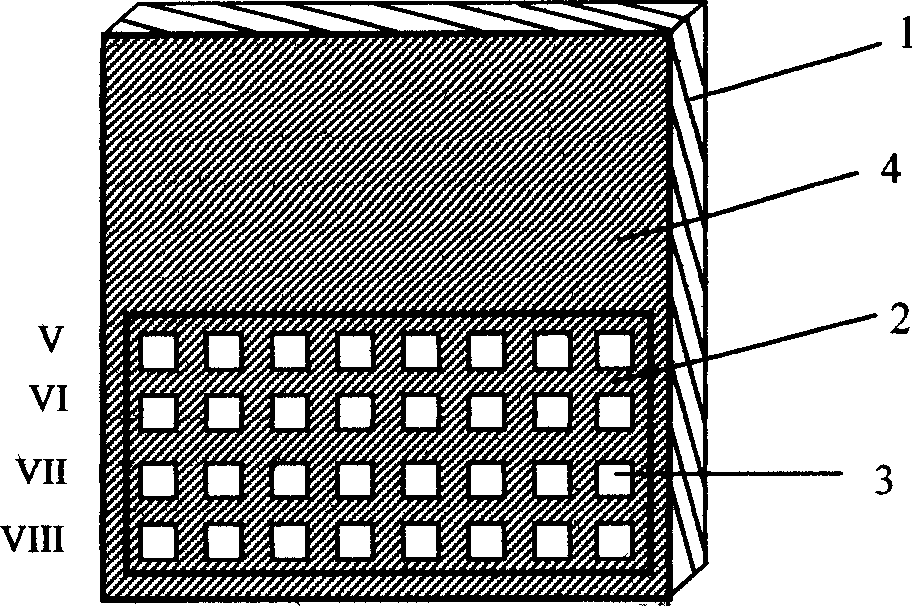

[0021] Such as figure 2 As shown in Figure A, the hollow area 5 carved out by the mask plate 4 is a horizontal rectangle and is located at the lower part of the mask plate, corresponding to figure 1 Rows V-VIII in the figure; Figure B shows that the hollow area 5 formed by the mask plate 4 is a vertical rectangle and is located on the right side of the mask plate, corresponding to figure 1 V-VIII columns in the figure;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com