Light aromatic hydrocarbon hydrogenation transformation device and operation method thereof

An operation method and technology for light aromatic hydrocarbons, which are applied in the directions of aromatic hydrocarbon hydrorefining, selective hydrorefining, and refining to remove heteroatoms, which can solve problems such as increased production costs, substandard products, and poor oil properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The accompanying drawings in the embodiments of the present invention will be combined below.

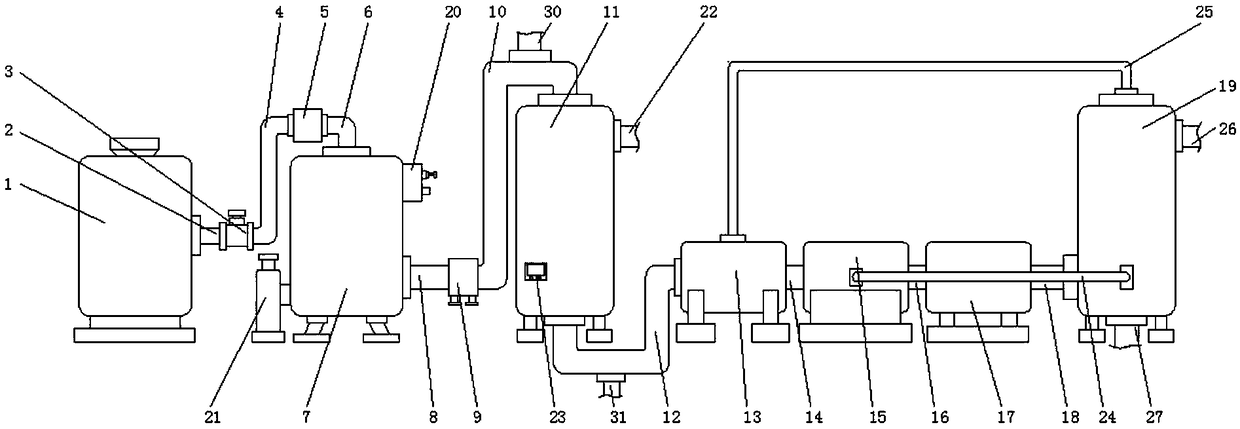

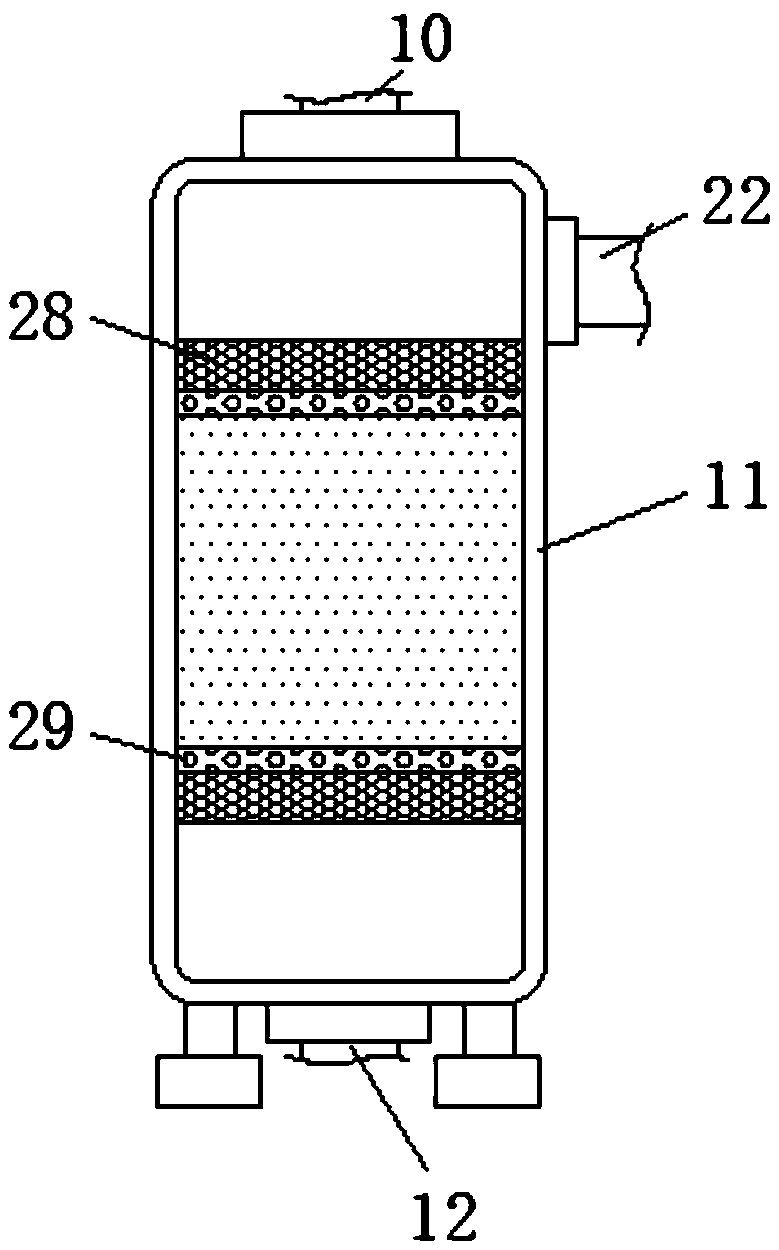

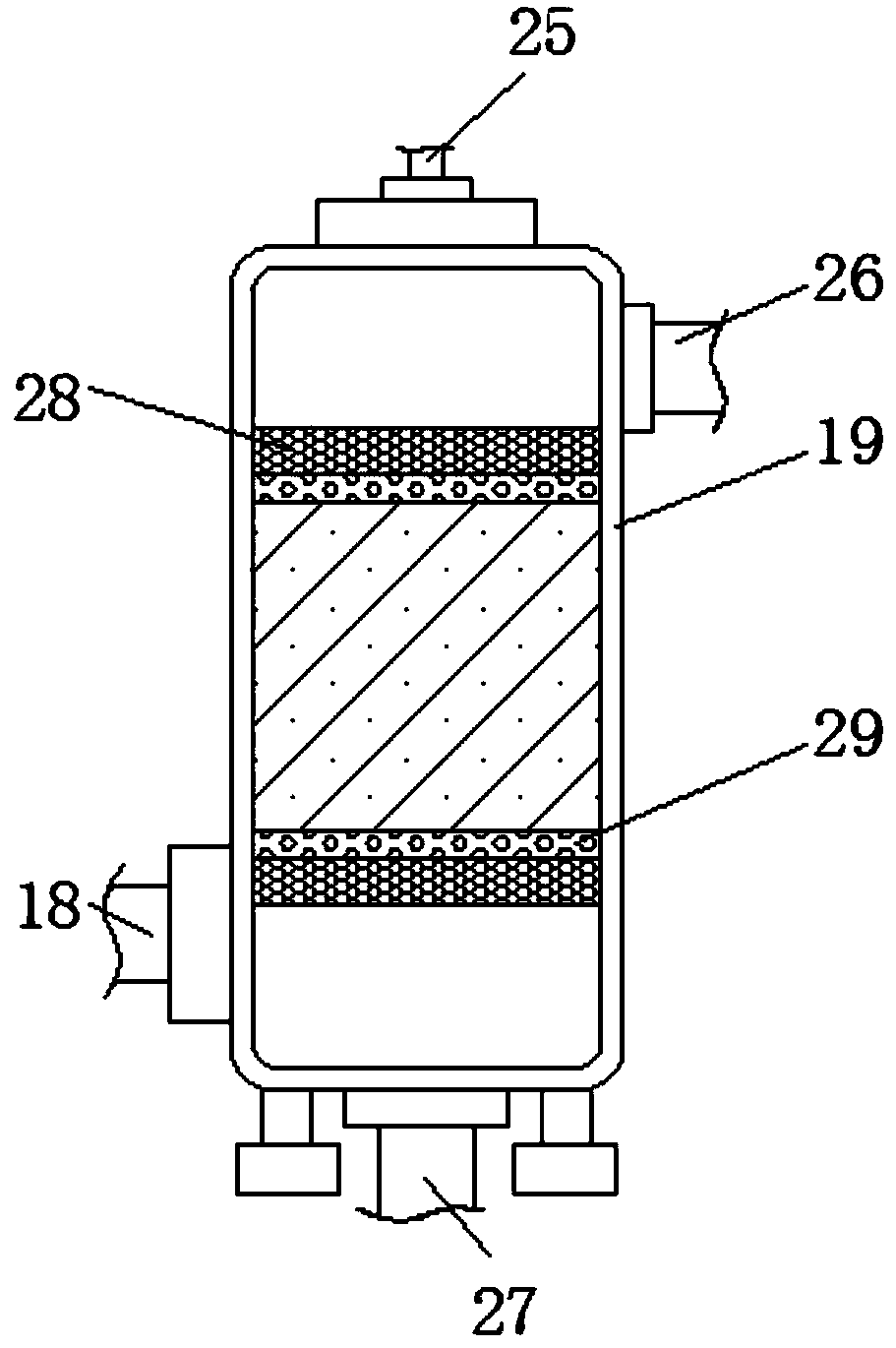

[0027] see Figure 1-3, a light aromatics hydrogenation modification device and operation method, comprising a raw material tank 1, a connecting pipe 2 is fixedly connected to the right side of the raw material tank 1, and a flow control valve 3 is fixedly installed on the right side of the connecting pipe 2, and the flow control valve 3 is The existing device, and the function of the flow control valve 3 is to control the flow of the light aromatic hydrocarbon raw material in the raw material tank 1, the model of the flow control valve 3 is VP542R-5DB-03A, and the right side of the flow control valve 3 is fixedly connected with a through pipe 4, The right side of the through pipe 4 is fixedly installed with a pre-hydrogenation heat exchanger 5, the pre-hydrogenation heat exchanger 5 is an existing device, and the function of the pre-hydrogenation heat exchanger 5 is to chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com