Oven and system and method for automatically measuring thermo-oxidative aging life of polymer material

A polymer material, thermo-oxidative aging technology, applied in the thermal development of materials, analytical materials, measuring devices, etc., can solve the problems of inability to guarantee the accuracy of thermo-oxidative aging life, unrealistic manual processing methods, and complicated testing processes. Achieve the effect of improving test stability, avoiding frequent out-of-box sampling, and simplifying the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

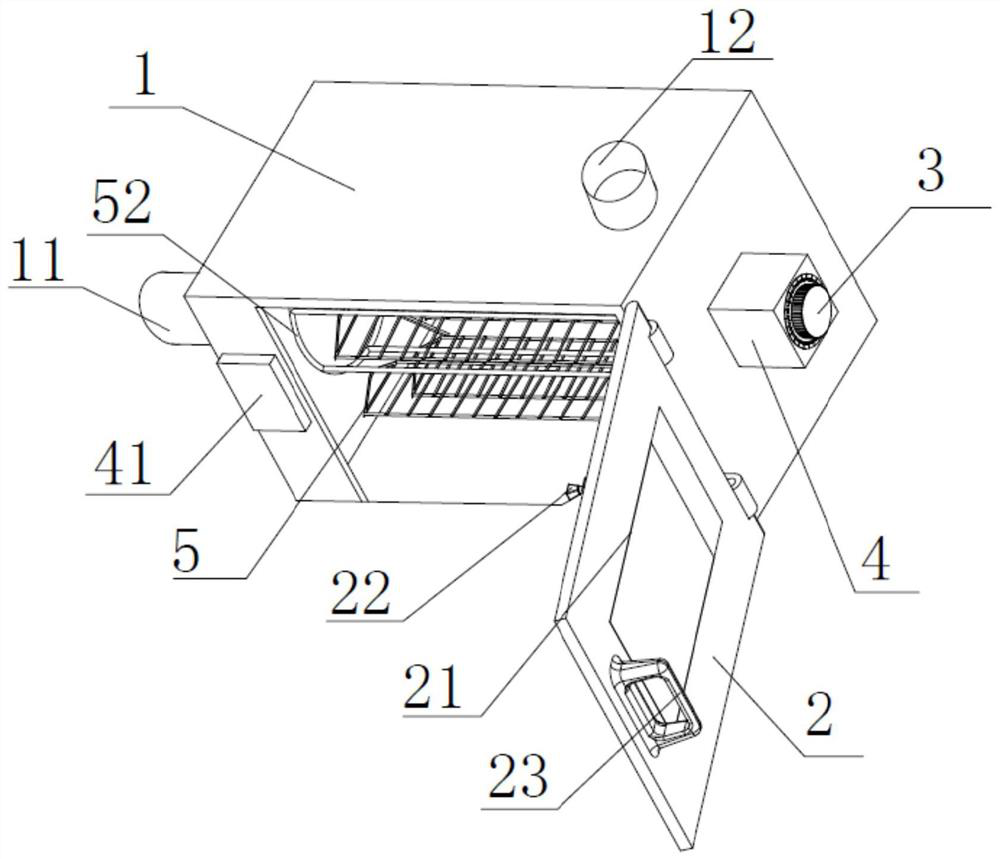

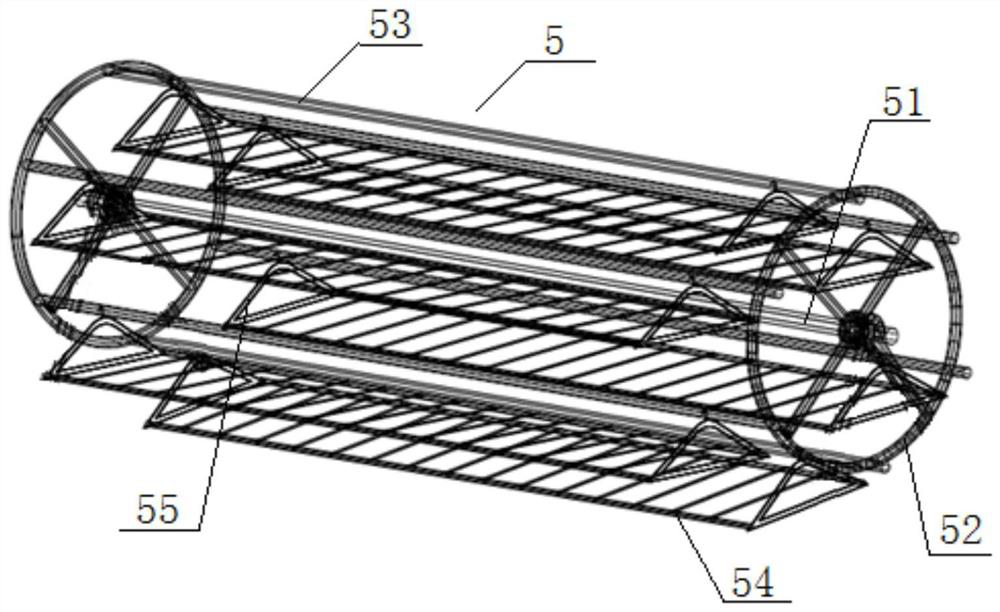

[0049] Such as figure 1 As shown, a kind of oven comprises box body 1, box door 2 hinged with box body 1, and box body 1 is provided with the sample rack 5 that is used to place sample, and box body 1 is provided with heating device; Box door 2 is installed There are 22 cameras.

[0050] The above-mentioned oven is provided with a heating device inside the box body 1. The heating device can heat and age the sample placed on the sample rack 5. The camera 22 can be used to take pictures of the sample, and judge whether the sample is aging and invalid according to the sample picture taken. Avoiding the problem of temperature deviation inside the oven caused by frequent opening of the oven is conducive to improving test stability and work efficiency. When the present invention is used for thermo-oxidative aging of polymer materials, the heating device performs thermo-oxidative aging of the polymer materials, the camera 22 can directly take pictures of the polymer materials, and t...

Embodiment 2

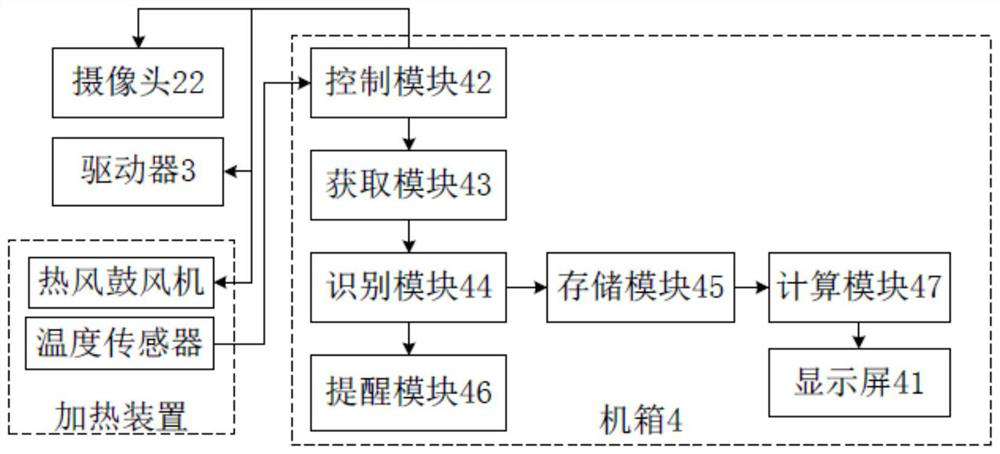

[0058] A polymer material thermo-oxidative aging life automatic measurement system, comprising the above-mentioned oven and cabinet 4, such as image 3 As shown, the chassis 4 includes a control module 42, a calculation module 47, a display screen 41, an acquisition module 43 for obtaining a gallery and a training sample set, an identification module 44 for identifying whether the image to be processed is an invalid image, The storage module 45 of storage failure picture and the reminding module 46 for warning, described camera 22, heating device are connected with described control module 42 respectively, and described acquisition module 43 is connected with camera 22, and described acquisition module 43, storage module 45 and the reminder module 46 are respectively connected to the identification module 44, the calculation module 47 is connected to the storage module 45, the display screen 41 is connected to the calculation module 47, and the heating device is used to heat an...

Embodiment 3

[0063] An automatic measurement method for thermal oxygen aging life of polymer materials, applied to the above-mentioned automatic measurement system for thermal oxygen aging life of polymer materials, such as Figure 4 shown, including the following steps:

[0064] S1: Put the sample into the sample rack 5, close the box door 2, preset the internal temperature of the box 1, set the shooting cycle of the camera 22, start the heating device, age the sample, and record the initial time t0 ;

[0065] S2: Use the camera 22 to photograph the sample according to the photographing cycle, obtain a gallery, and record the photographing time t′ of each photographing 0 ;

[0066] S3: Use the acquisition module 43 to acquire a gallery from the camera 22, the gallery includes at least one image to be processed;

[0067] S4: Input the pictures to be processed into the identification module 44 respectively, and use the identification module 44 to identify the pictures to be processed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com